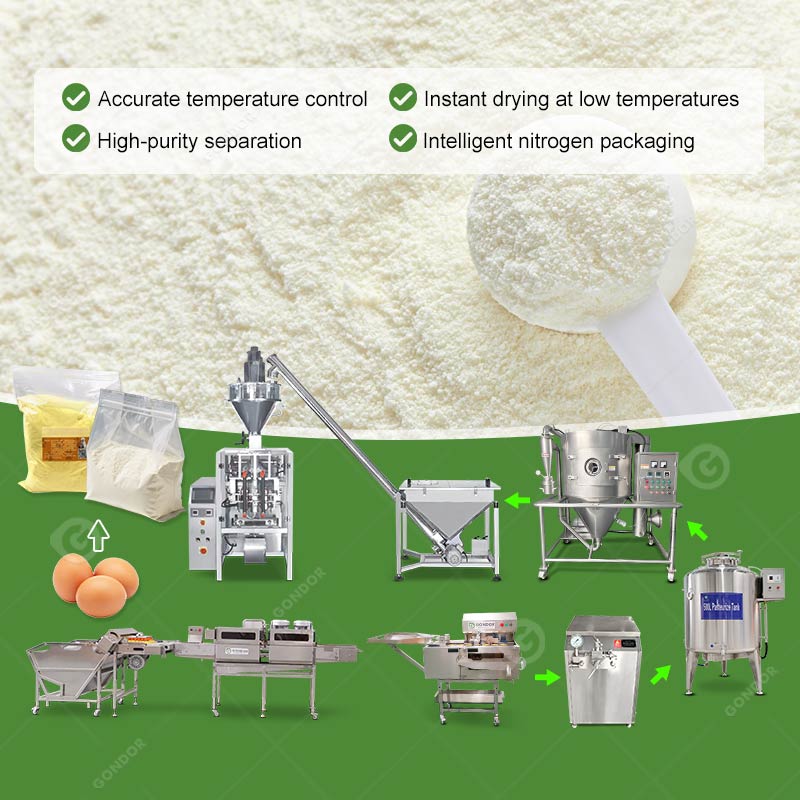

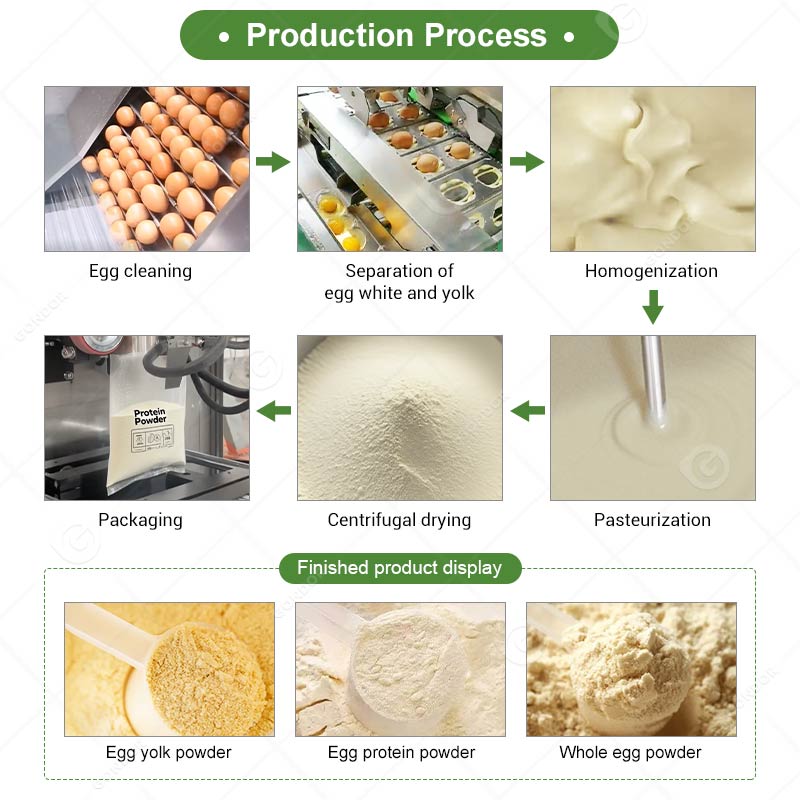

The egg powder production line is an advanced, automated system specifically designed to process fresh eggs into high-quality egg powder. Through precise temperature control, high-purity separation, and low-temperature spray drying, the system fully retains the nutrition and functionality of egg powder. The whole line integrates many processes such as egg cleaning, separation, homogenization, pasteurization, and intelligent packaging. Therefore, it is very suitable for large food enterprises and nutritional supplement manufacturers. In addition, this system can be flexibly adapted to ordinary eggs, selenium-enriched eggs, or organic eggs. Finally, egg white powder, egg yolk powder, whole egg powder, and a variety of customized protein powder products can be produced.

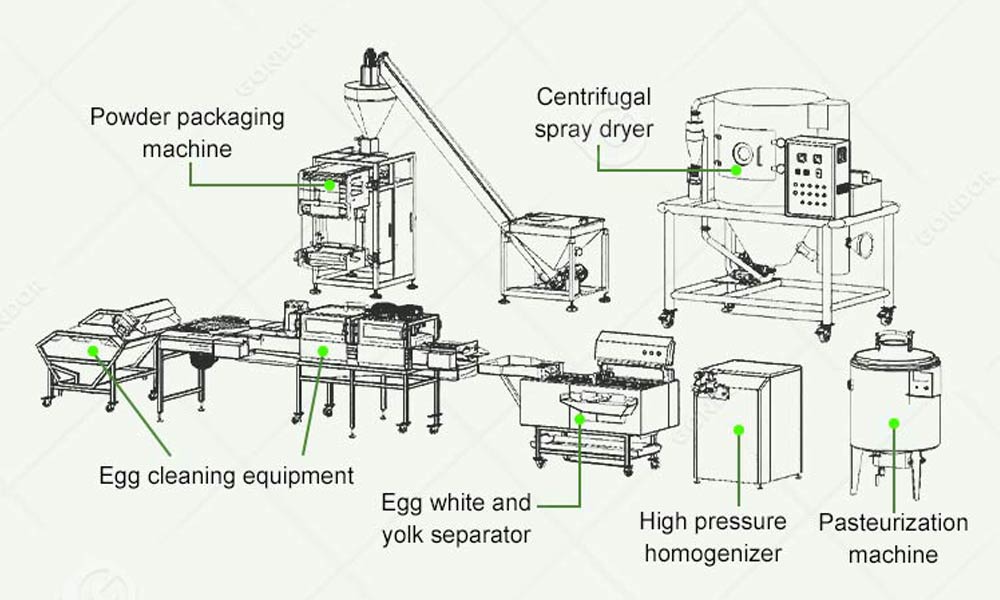

| Machine Name | Voltage | Power | Material | Size |

| Egg cleaning and drying machine | 220V | 2.1kw | Stainless steel | 2840*550*1400mm |

| Egg white and yolk separator | 220V | 0.4kw | 1700*980*1280mm | |

| High-pressure homogenizer | 220V | 2.2kw | 755*520*935mm | |

| Pasteurization machine | 380V | 9kw | 1400*800*1400mm | |

| Centrifugal spray dryer machine | 380V | 17.5kw | 2000*900*1900mm | |

| Screw powder filling machine | 220V | 2.2kw | 1424*980*1343mm |

Market Application of Egg Powder Production Line

With the increasing global demand for protein powder, its high nutritional value, good solubility, and multi-functional characteristics are promoting the expansion of multi-industry applications. The protein powder production line can help enterprises accurately meet the needs in the following fields:

Superior Advantages of Egg Powder Making Machine

Why Choose Gondor Whey Protein Production Line?

- Flexible Expansion: It can support small and medium-sized capacity improvement or automation transformation of large enterprises.

- Wide Adaptation: Suitable for food, nutritional supplements, cosmetics, and other industries.

- Compatibility of Raw Materials: It can handle a variety of egg raw materials and flexibly produce different forms of end products.

- Standard Compliance: It conforms to international quality and safety standards and easily meets export certification.

- Sustainable Profit: Realize stable production through automation, significantly reduce costs, and improve efficiency, with considerable returns.

Equipment Recommendation

To help customers further improve the production system, we also provide other equipment, such as:

- Milk Powder Production Line

- Automatic Cartoning Machine

By integrating these systems, your factory can realize a more comprehensive protein powder processing solution to meet the diverse raw materials and global market demand. Whether you are in the food processing industry, the nutritional supplements industry, or the cosmetics industry, this production line can bring you efficient, reliable, and sustainable productivity.