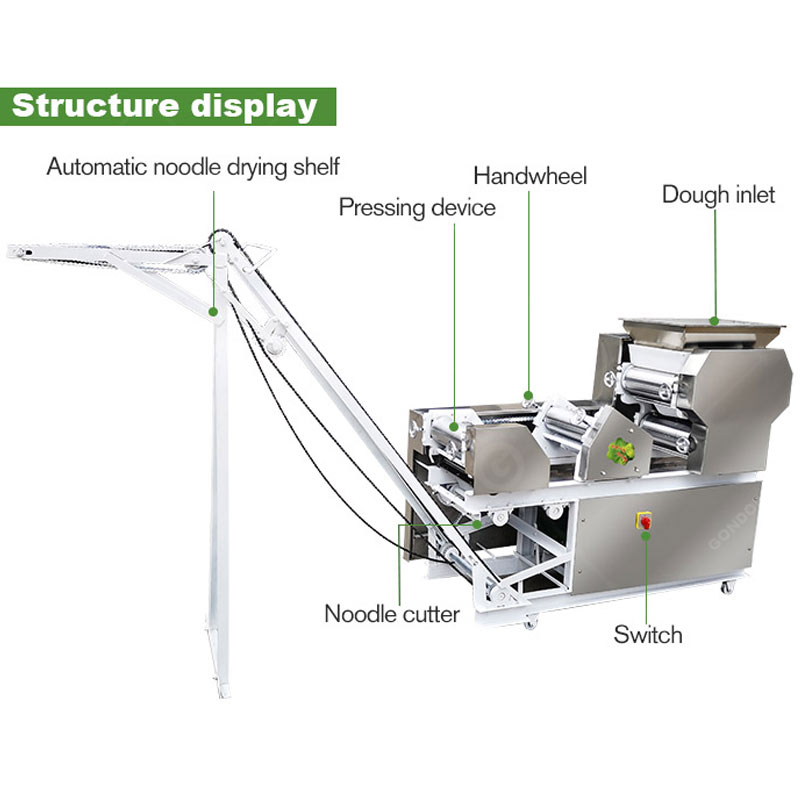

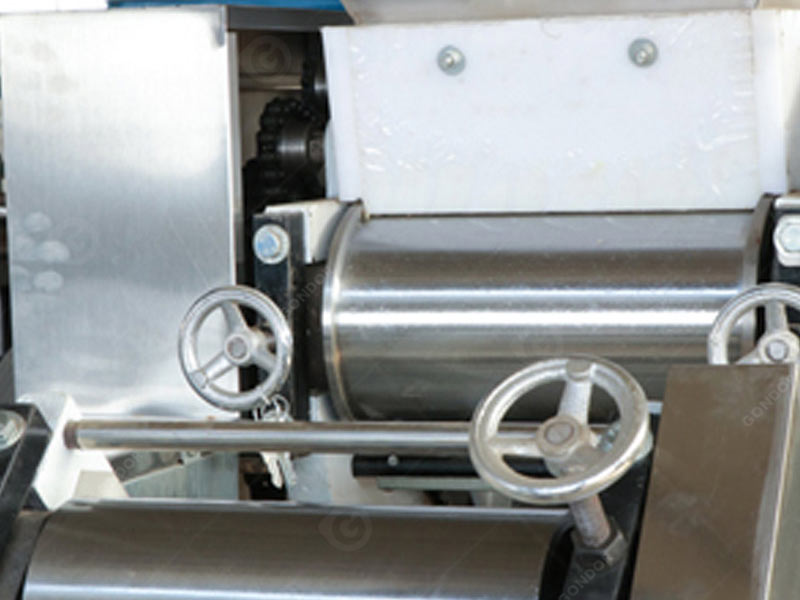

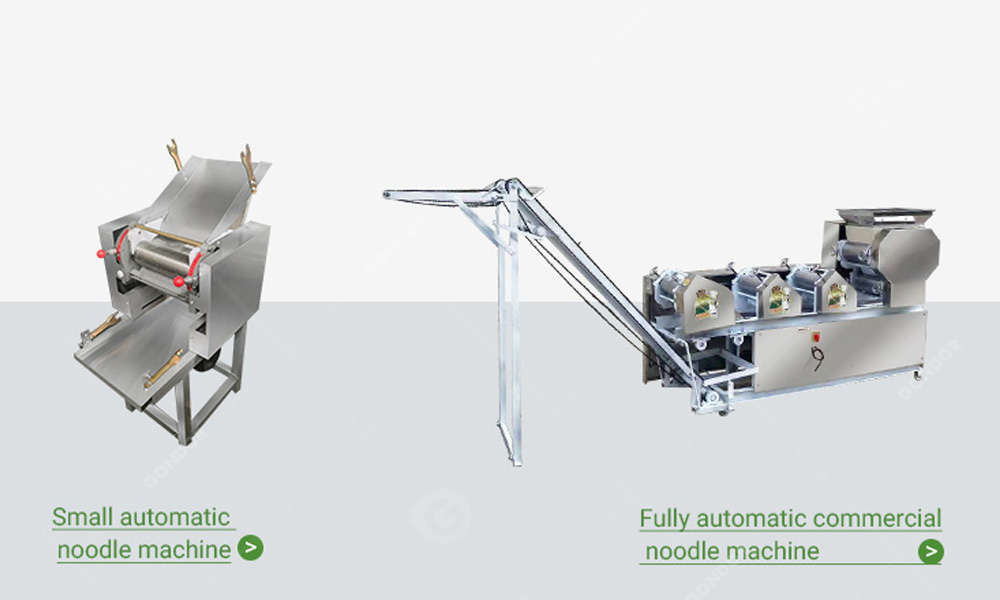

Fully automatic noodle making machine is an efficient and convenient kitchen equipment, which can quickly produce a large amount of noodles due to its high degree of automation and adjustable noodle thickness. And it has a compact structure, simple operation, and easy cleaning. It is suitable for noodle workshops, restaurants, canteens and other places, which can greatly improve the efficiency of noodle production and meet the needs of different groups of people for fresh noodles. In short, it is a great helper for making noodles, allowing people to easily enjoy delicious noodles and save time and energy.

Gondor Automatic Noodle Machine Parameter

| Model | Capacity | Parameter | Power | Weight | Machine Size |

| 5 group 250Dry noodles machine | 170kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 550 | 1700*610*1370 |

| 5 group 300Dry noodles machine | 260kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 650 | 1700*750*1370 |

| 5 group 350Dry noodles machine | 280kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 800 | 1700*780*1370 |

| 5 group 250Fresh noodles machine | 170kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 600 | 1700*610*1370 |

| 5 group 300Fresh noodles machine | 260kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 700 | 1700*750*1370 |

| 5 group 350Fresh noodles machine | 280kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 950 | 1700*780*1370 |

| 6 group 260Dry noodles machine | 170kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 860 | 2000*650*1370 |

| 6 group 300Dry noodles machine | 260kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 910 | 2000*680*1370 |

| 6 group 350Dry noodles machine | 280kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 990 | 2000*730*1370 |

| 6 group 260Fresh noodles machine | 170kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 910 | 2000*650*1370 |

| 6 group 300Fresh noodles machine | 260kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 950 | 2000*680*1370 |

| 6 group 350Fresh noodles machine | 280kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 990 | 2000*790*1370 |

| 7 group 260Dry noodles machine | 170kg | Main roller diameter 138other roller diameter 120 | power 3 kw | 980 | 2600*680*1370 |

Industries Suitable for the Gondor Fully Automatic Noodle Machine

With the help of this equipment, chain noodle restaurants can ensure a stable and fresh supply of noodles, create a unique noodle brand, and win the favor of customers.

Quick-frozen food factories use fully automatic noodle machines to quickly make noodles and then quickly freeze them to produce quick-frozen fresh noodles products for a wide market.

Medium and large restaurants use noodle machines to make fresh noodles and present special noodles to customers, ensuring the taste quality and attracting diners.

Professional noodle processing factories must have large-volume noodle machines to efficiently produce multiple types of noodles to meet large-scale market demand and enhance competitiveness.

Supermarkets and convenience stores use fully automatic noodle machines to make fresh noodles for sale, meet consumers’ demand for fresh and healthy food, and increase sales.

Significant Working Advantages of the Gondor Automatic Noodle Machine

- Through precise mixing and kneading force control, the dough can be fully and evenly mixed, and the noodles produced have a strong taste. It is more uniform and consistent than handmade noodles, and the quality is stable.Strong Taste

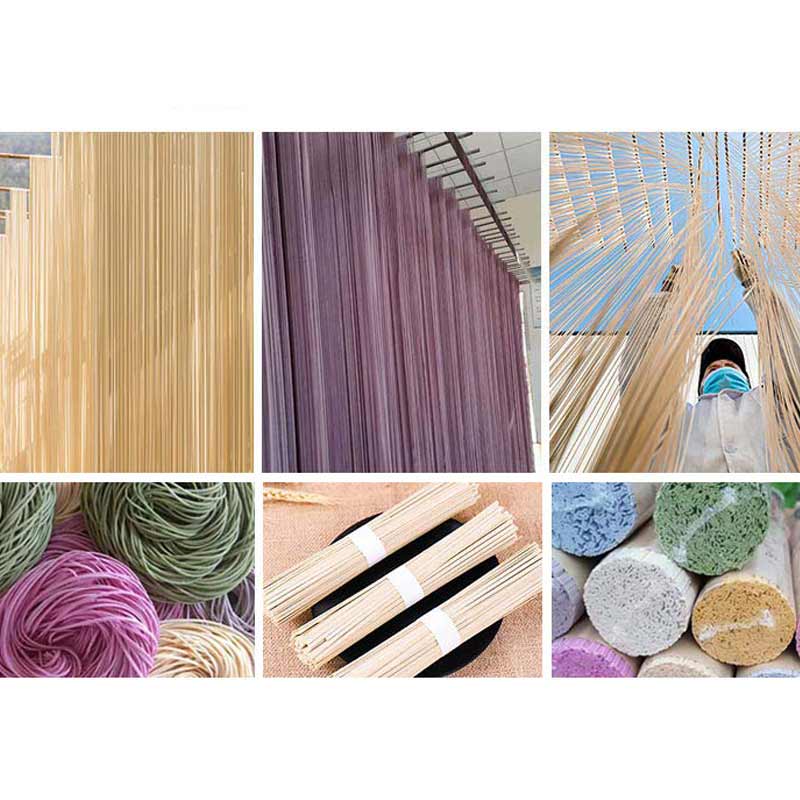

- Adjust the shape and thickness of noodles according to different needs, such as thin noodles, wide noodles, etc., to meet different taste preferences. It can also make various special noodles, such as ramen, etc.Diversified Production

- For restaurants, canteens and other places, it can reduce labor costs and improve production efficiency. At the same time, making noodles yourself is more economical than buying ready-made noodles.Cost Saving

- It can quickly complete the entire process from mixing to making noodles, greatly saving time and energy in making noodles. Fresh noodles can be easily obtained without repeated kneading and rolling.Efficient and Convenient

- Made of food-grade materials, safe and reliable contact with food. Made in a closed environment, it reduces the possibility of external pollution and ensures the sanitary quality of noodles.Hygiene and Safety

- Reasonable design, detachable parts, easy to clean. No flour and dough will remain, keeping the machine clean and hygienic, providing good conditions for the next use.Easy to Clean

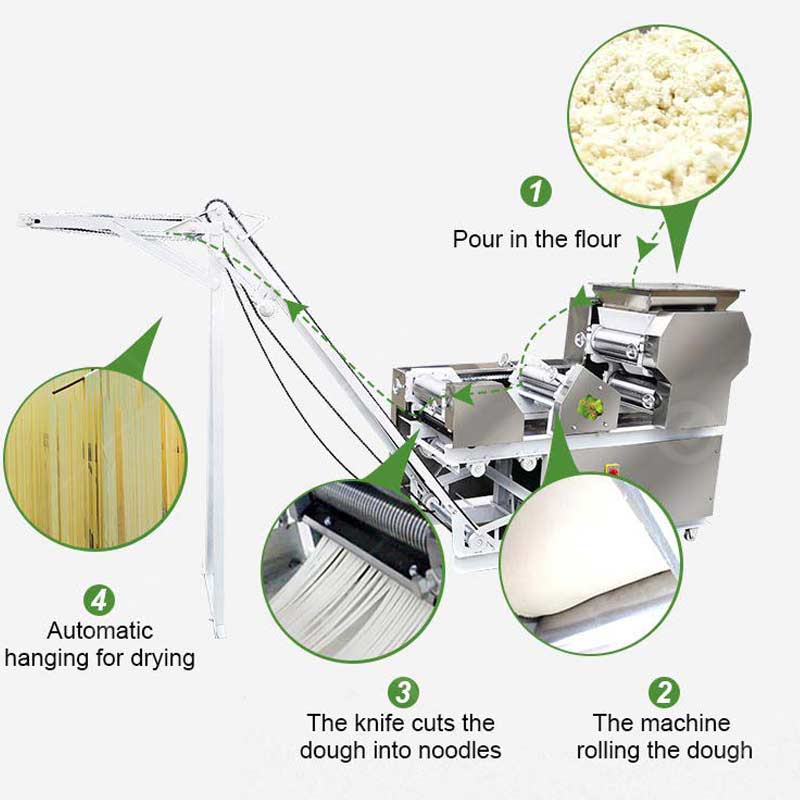

Working Steps of Gondor Automatic Noodle Machine

Gondor Fully Automatic Noodle Making Machine – Delicious and Easy to Make

Want to taste fresh and chewy noodles at any time? Gondor’s fully automatic noodle making machine is undoubtedly your best choice. Because it is efficient and convenient, you can quickly make noodles with just one button. And the taste is chewy, comparable to handmade. At the same time, the equipment is made of stainless steel, which is durable and easy to clean. In short, whether it is a large noodle processing factory or a restaurant canteen, our automatic noodle machine can bring you deliciousness and convenience, come and order it!