Gondor Fully Automatic Potato Chips Line

Fully automatic potato chips production line from Gondor machinery will be your ideal selection to improve your business of manufacturing commercial potato chips. And our potato chips production lines are specially designed for large-scale production of different potato chips for different customers. Moreover, Gondor fully automatic potato chips line has the advantages of high automation, ongoing production, Superior efficiency, reduced manpower, and energy conservation. Dedicated to product innovation and customer satisfaction, Gondor will be your trusted partner to ensure a good margin for your business!

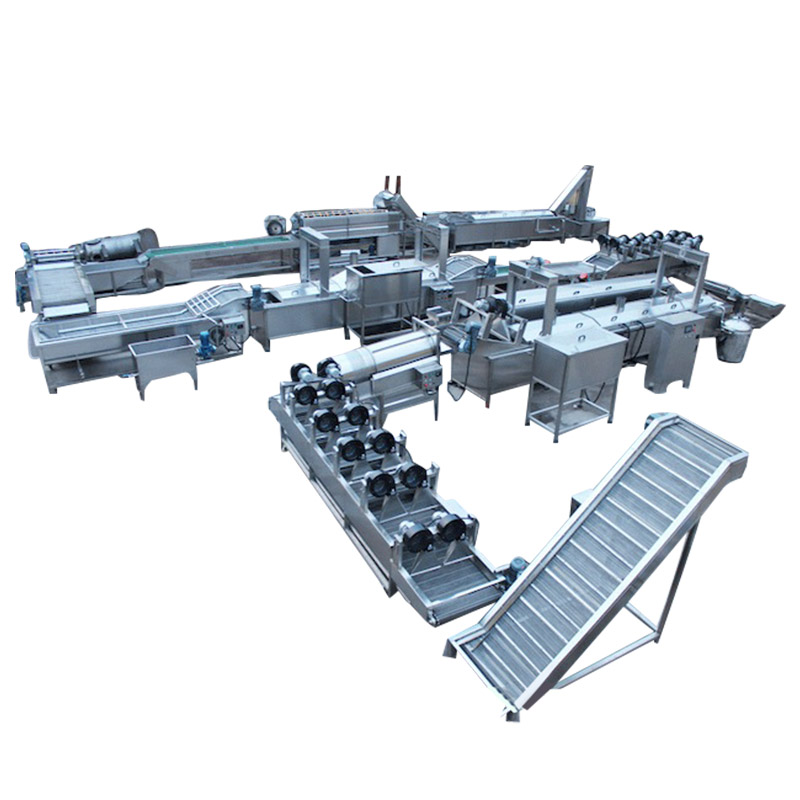

Fully Automatic Fresh Potato Chips Production Line in Gondor Machinery

Brief Introduction of Gondor Potato Chip Production Line:

As a professional potato chips line manufacturer, Gondor can elevate your snack production with our state-of-the-art automatic fresh potato chips production line. The chips production line is composed of a lifting machine, cleaning and peeling machine, sorting line, potato chips cutter, bucket elevator, descaling machine, and a continuous frying machine and these machines adopts are manufactured in our factory with advanced technology.

Besides, our production line stands out with its use of high-quality 304 stainless steel and high PLC electrical control for unparalleled reliability and efficiency. Equipped with top-grade imported stainless steel bearings and renowned brand-name electrical components, this line represents the pinnacle of technology in the snack food industry.

Buy Automatic Potato Chips Machinery from Gondor Machinery

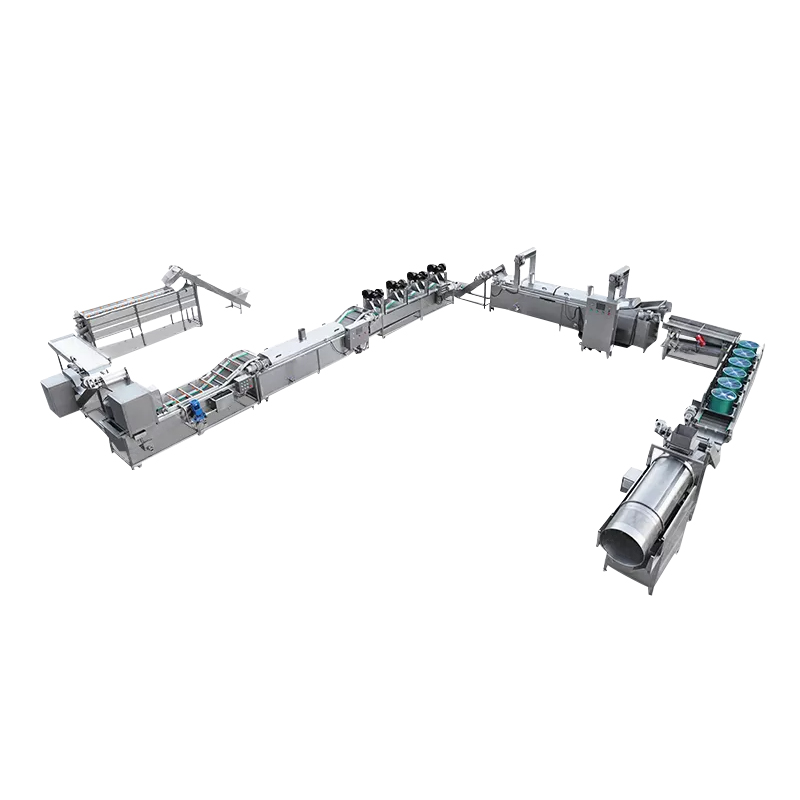

Gondor Fully Automatic Potato Chips Processing Line in the Factory

Fully Automatic Potato Chips Line Applications in Gondor Machinery:

As we know, the fully automatic fresh potato chips production line is an all-in-one solution for businesses aiming to produce high-quality commercial potato chips at a large scale, which is ideal for large-scale snack processing factories and potato chip manufacturing facilities. Therefore, it is essential in various sectors, which has a promising market prospect. Here are some of the key applications of a fully automatic potato chips line from Gondor group:

Food Service Industry

1. Catering Services: They can benefit from the fully automatic potato chips-making line to produce high volumes of snacks efficiently for events, sports arenas, and airlines.

2. Restaurants and Fast-Food Chains: With the chips processing line, they can offer freshly made potato chips as part of their menu, which can enhance customer satisfaction with fresh and tasty snacks.

Retail and Supermarkets

1. Private Label Production: As for some supermarkets and retail chains, they often use the potato chips lines to produce their own potato chips, which allows them to control the quality, flavor, and cost of their products.

2. Ready-to-Eat Snack Sections: Some retailers can offer freshly made potato chips in their ready-to-eat snack sections, which is a unique selling point and can attract more customers.

Innovative Product Development

1. New Flavors and Varieties: The flexibility of fully automatic potato chips lines allows snack manufacturers to experiment with new flavors, shapes, and textures, catering to evolving consumer preferences and trends.

2.Healthier Options: With the growing demand for healthier snacks, Gondor has the chips production lines to produce low-fat, low-salt, or organic potato chips to help our customers make a big profit.

Industrial and Institutional Use

1. Large Institutions: Provides snacks for schools, hospitals, and military bases.

2. Food Processing Plants: Streamlines production in plants specializing in potato products.

3. Large Institutions: Some institutions like schools, hospitals, and military bases, will buy and use the potato chips line to produce large quantities of potato chips for their residents or members, which can guarantee a steady supply of snacks.

4. Food Processing Plants: The production lines adopts advanced technology and configuration, which can streamline the production process and improve the overall efficiency. Thus, it is indispensable for food processing plants specializing in potato products.

Commercial Food Production

1. Snack Manufacturing: This is a primary users for this chips production line, which can ensure consistent quality and high production rates for large snack companies.

2. Contract Manufacturing: These companies will use the lies to produce potato chips for various brands with specific recipes and standards.

Export and International Markets

With the advanced technology and hygiene standards, the fresh potato chips production line in Gondor machinery can meet international food safety and quality regulations. Meanwhile, the consistency in quality and production volume helps in establishing a strong presence in global markets.

Main Features of Fully Automatic Fresh Potato Chips Production Line

The fully automatic fresh potato chips production line is designed to cater to the ever-growing demand for high-quality, crispy potato chips. This advanced machinery ensures efficiency, consistency, and quality in every batch. Here are the main features that make this production line a top choice for worldwide customers. Embrace the future of snack production with our Automatic Fresh Potato Chips Production Line – a blend of technology, efficiency, and quality.

- Choose from electricity, gas, steam, or electromagnetism to suit your operational needs.Versatile Heating Options

- Set your desired frying time with automatic temperature control ranging from 0-300°C.Precision Frying

- The double mesh belt ensures even frying, with adjustable speed for optimal results.Adjustable Conveyor Speed

- Comes with an oil filter machine, oil tank, and mesh lifting system for efficient oil usage and easy cleaning.Oil Management

- Optional fire-extinguishing and refined oil filtration devices enhance safety and oil quality.Safety Features

- Easy control settings and maintenance procedures make it suitable for various operational scales.User-Friendly Operation

Automatic Potato Chips Production Line Equipment in Gondor

Fully Automated Potato Chips Production Lines: Key Components

Thanks to the advanced photo chips production lines, businesses or investors can handle large volumes of potatoes, transforming them into crispy, delicious chips with minimal human intervention step by step. In the whole process of snack food production, each step will be meticulously handled by specialized machines to guarantee the efficiency, consistency, and high-quality output. At the same time, these machines can streamline the production process and are key components that compose the fully automated potato chips production lines. Here are some details about these key components:

Washing and Peeling Machine

At first, the automatic chips production lines begin with this washing and peeling machine, and it adopts the high-pressure water and brushes to clean the photos thoroughly, which is prepared for the next step.

Slicing Machine

Upon completion of the washing, the washed and peeled potatoes are fed into the slicing machine, and then the machine slices them into thin and uniform pieces. Additionally, the slice thickness can be adjusted.

Blanching Machine

Next, in the blanching machine, the potato slices are briefly cooked in hot water or steam to eliminate the excess starch as well as improve the texture of the photo chips. In addition, it also can preserve the natural color of chips.

Dehydrator

This step aims to achieve the preferred finished products. The dehydrator will remove excess moisture from the slices photo slices to guarantee the crispiness. What’s more, our production lines with higher efficiency can reduce the frying time and oil absorption, which makes it a healthier snack.

Frying Machine

The dehydrated slices are fried in a frying machine to turn them into crispy chips. And our automatic chips processing lines maintain a consistent temperature and use high-quality oil to ensure the chips can be cooked to perfection.

De-oiling Machine

Once fried, the chips go through a de-oiling machine to remove excess oil, and this makes them less greasy and extends their shelf life, which is attractive for health-focused consumers.

Seasoning Machine

Before packing, the photos chips are then evenly coated with flavors in a seasoning machine, such as salt, cheese, barbecue, or any other desired seasoning, which will ensure the same great taste.

Packaging Machine

Finally, the final products are sealed in airtight bags by a packaging machine, in order to maintain the freshness and chip quality.

De-oiling Machine

Once fried, the chips go through a de-oiling machine to remove excess oil, and this makes them less greasy and extending their shelf life, which is attractive for health-focused consumers.

Automatic Fresh Potato Chips Production Line Parameter in Gondor

The automatic potato chips production line is capable of automatically cleaning, peeling, cutting, and controlling moisture levels during drying, frying, managing oil levels, seasoning, and other processes necessary. During the production of potato chips, each component of the potato chips production lines work together seamlessly and high effectively, which can streamline the production process to produce and package high-quality, the low-fat french fries and fresh potato chips. Here are some main parameters for this production line to our clients to make reference, and feel free to contact us for more product details here!

Fully Automatic Potato Chips Production Line Specification

| Device name | Power(kw) | Voltage(V/Hz) | Dimensions(mm) |

| Hoist | 0.75 | 380/50 | 1500*1800*1500 |

| Washing and Peeling Machine | 4.75 | 380/50 | 3000*900*1500 |

| Picking Line | 0.75 | 380/50 | 4000*1000*900 |

| In addition to Water Machine Vibration | 1.5 | 380/50 | 2000*1000*1300 |

| Fries Machine Potato Chips | 1.5 | 380/50 | 1300*900*1500 |

| Washing Machine | 5.5 | 380/50 | 4000*1200*900 |

| Blanching Line | 125 | 380/50 | 5000*1200*950 |

| Air-dryer | 15 | 380/50 | 5000*1200*1400 |

| Electrically Heated Frying Line | 203 | 380/50 | 5000*1200*2400 |

| Wind-blown Leacher | 15 | 380/50 | 4000*1200*1500 |

| Vibration Degreasing Machine | 1.5 | 380/50 | 2000*1000*1300 |

| Roller Seasoning Machine | 0.75 | 380/50 | 3500*1200*1000 |

Processing Flow of Gondor Fully Automatic Potato Chips Production Line

A fully automatic potato chips production line is a comprehensive set of snack machines designed to manage every step in the production of potato chips. It covers everything from washing and peeling raw potatoes to blanching, dehydrating, frying, de-oiling, seasoning, and packaging the final product. What’s more, the potato chips production line with high automation can guarantee consistent quality, taste, and texture, aligning with the high standards expected by consumers and regulatory authorities.

Market Prospects for Fully Automatic Potato Chips Production Lines

In recent years, because of the increasing consumer demand for convenient snacks, the global market of photo chips is increasing rapidly. For the purpose of meeting the changing market demands, our company is pleased to introduce the fully automated potato chips production lines with different capacities. It can help our customers stand out in this competitive market. With advanced technology, customized solutions, and a focus on efficiency and quality, Gondor production lines are ideal selections for investors looking to excel in the growing market.

Contact Gondor to Buy Potato Chips Production Lines

The fully automatic potato chips production line revolutionizes the snack manufacturing industry. By integrating advanced technology and automation, it not only boosts production efficiency and consistency but also ensures high-quality and safe products. Therefore, many investors choose to invest in the fully automatic potato chips production line to meet the dynamic demands of today’s snack-loving consumers, which is a strategic and forward-thinking decision.

Do not hesitate to contact Gondor machinery for more product details and our team of experts is ready to assist you in revolutionizing your snack manufacturing process. As a top manufacturer of food processing equipment, Gondor can customize the potato chips processing line to satisfy the different demands of our customers worldwide. And we are ready to assist you in revolutionizing your snack manufacturing process, which promotes your business to stay ahead in the competitive snack market.