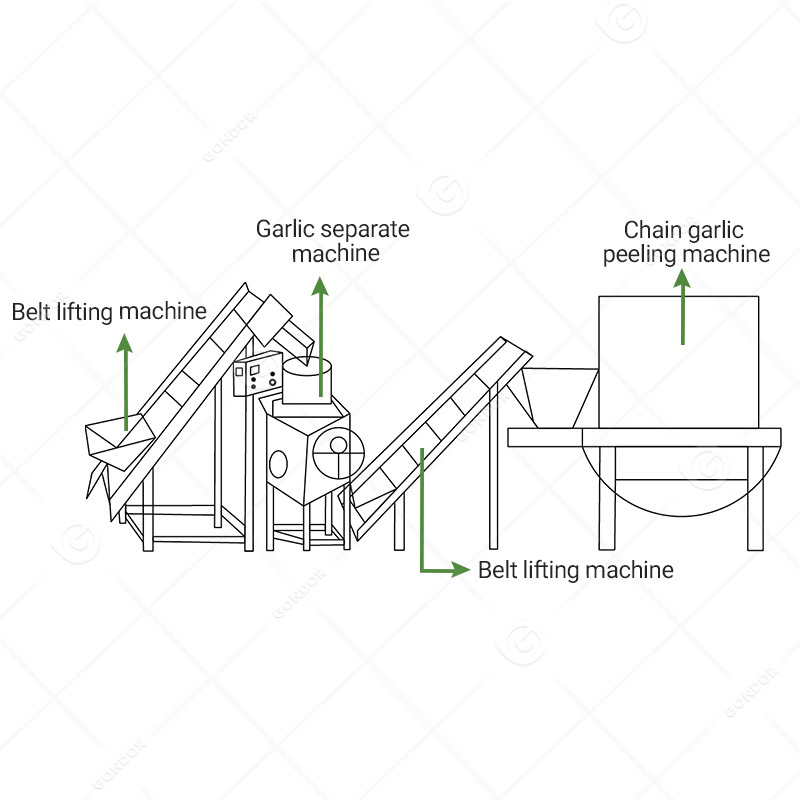

The garlic peeling production line is a set of highly intelligent, efficient, and reliable production systems. It is mainly used for the large-scale separation and peeling of garlic, including an elevator, garlic separator, chain garlic peeling machine and other machines. Gondor machinery provides the garlic peeling processing lines for our customers and our clients span across the globe. And they choose to purchase from Gondor machinery to increase productivity and quality with our advanced machinery or lines. Get in touch with us for a free consultation about the automatic garlic peeling production line in Gondor Group!

High-Efficiency Garlic Peeling Production Lines in Gondor

Different Models of Gondor Garlic Peeling Production Lines

In Gondor machinery, we offer various automatic garlic peeling production line models that can be customized based on the specific requirements of our customers and their desired production capacity. Whether you are looking forward to purchasing a small-scale setup for local production or a larger, industrial-grade line for mass production, the Gondor garlic peeling machine line can be tailored to meet your demands. Moreover, our processing lines for garlic adopt an advanced system that can ensure a seamless transition from whole garlic to perfectly peeled cloves. Furthermore, and even more significantly, it can maintain high productivity and quality throughout the whole process. The bellows are some main models of the garlic peeling production line from Gondor group:

| Products | Model | Motor power | Capacity | Gross Weight | Dimension(cm) |

| Conveyor | GD-130 | 0.75kw | / | 130kg | 220*70*150 |

| Garlic Separate Machine | GD-500 | 1.12kw | 500kg/hr | 135kg | 80*74*114 |

| Garlic Separate Machine | GD-1000 | 2.05kw | 1000kg/hr | 165kg | 150*73*120 |

| Garlic Peeling Machine | GD-400 | 1.0kw | 400kg/hr | 240kg | 160*50*145 |

| Garlic Peeling Machine | GD-600 | 1.0kw | 600kg/hr | 280kg | 180*58*152 |

| Garlic Peeling Machine | GD-1000 | 2.25kw | 1000kg/hr | 450kg | 310*100*200 |

Energy-Saving Garlic Peeling Machine for Sale in Gondor

High-Output Garlic Peeling Machine from Gondor Machinery

Why Invest in Garlic Peeling Production Line?

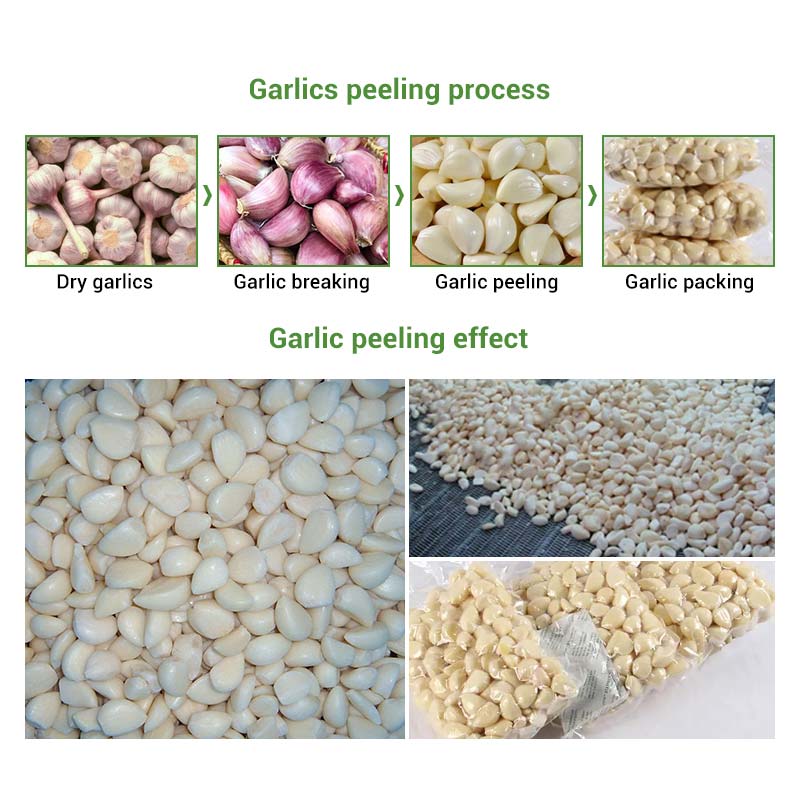

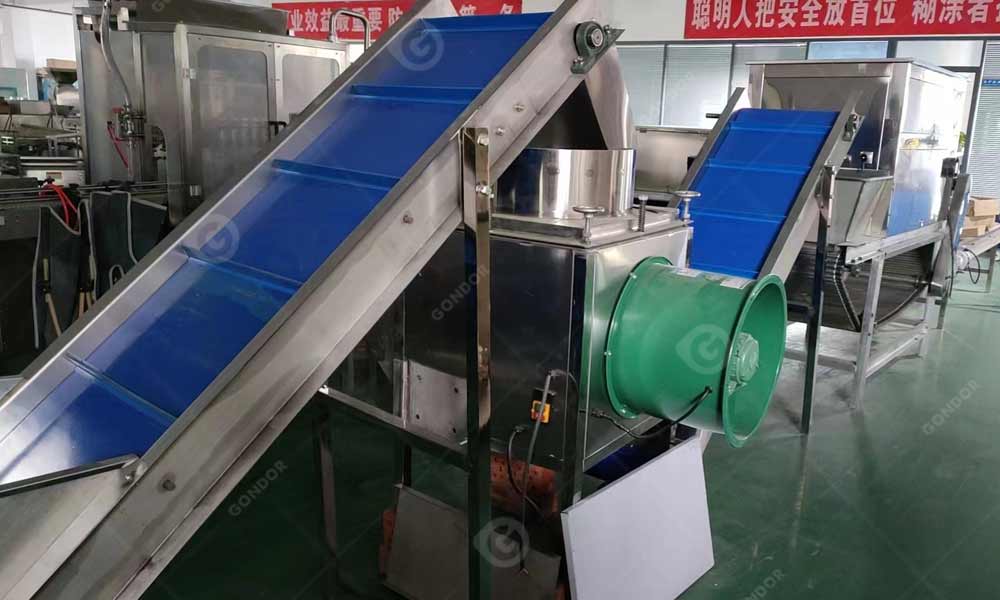

The garlic peeling production line transports garlic via stainless steel tracks and uses compressed air to blow off the garlic skin, achieving damage-free peeling. And it is composed of 304 stainless steel, which is fairly durable. Besides, the use of high-tech for high-quality peeling of garlic and onions is currently the most ideal tool for peeling.

On the other hand, the dry stripping method of the automatic garlic peeling processing line does not require water, so the production line not only can avoid the waste of water resources but also complies with current environmental policies. In addition, it reduces labor costs and ensures consistency and stability in product quality, which can guarantee the increased productivity and enhanced operational efficiency. Meanwhile, as for the large-scale industrial production and small to medium-sized enterprises, the high precision and reliability of the equipment contribute to a significant reduction in waste, which can ensure optimal use of raw materials and maximize profitability.

Garlic Peeling Line for Large Scale Production

Automatic Garlic Peeling Processing Line Application

Automatic garlic peeling processing lines in Gondor machinery are ideal sections for different sectors including the food processing industry, restaurant, agricultural product processing enterprise, seasoning and spice producers, and food research and development institutions. This peeling production line has well-equipped facilities and can operate efficiently, and so it can guarantee the rapid peeling of garlic for different investors. If you have a demand for this garlic peeling processing line or other production lines, do not hesitate to get in touch with our team for more information and personalized support here!

Main Features of Gondor Automatic Garlic Peeling Production Lines

By choosing to buy the automatic garlic peeling production lines in Gondor, businesses can benefit from the combination of high efficiency, superior quality, and reliability. In this way, Gondor machinery can stay competitive in the fast-paced food processing industry. In addition, Gondor automatic garlic peeling production lines are designed for maximum efficiency and speed. We utilize advanced technology to peel large quantities of garlic in a shorter time, reducing labor costs and increasing productivity. The peeling process is streamlined to ensure that each clove is peeled perfectly in a matter of seconds. Check below to know some main features of this production line and contact us for more product details!

- It is engineered to handle garlic gently, which can preserve the integrity and quality of the cloves. And it is obvious that less waste and higher yield are crucial for businesses looking to maximize their output.Minimal Damage to Garlic

- Our factory adopts high-quality stainless steel to manufacture our garlic peeling lines, and it is easy to clean and resistant to corrosion. Besides, the unique design also minimizes the risk of contamination, which ensures the highest food safety standards.Hygienic and Safe Operation

- For the purpose of satisfying the unique needs of different businesses, Gondor offers customized garlic peeling production lines. Therefore, global customers can choose from a range of options and configurations from our factory.Customizable Solutions

- The automatic system will streamline the entire peeling process. And it can ensures a seamless and consistent operation during the whole process, which can reduce the need for manual intervention.Integrated Automation

- The machine uses electricity as its energy source, featuring low energy consumption. In addition, the dry stripping method does not pollute the environment and complies with environmental policies.Energy conservation

- This production lines can be used in various industries such as food processing plants, catering services, and agricultural product processing enterprises.Widely applicable

- The device has a simple intuitive interface, making it easy to operate. Easy to clean and maintain, meanwhile, reducing downtime.Simple operation

- The production line is designed with full automation, enabling rapid peeling and significant labor cost savings.High Efficiency

- Each garlic clove achieves a consistent peeling effect to ensure the stability of product quality.Quality Assurance

- The equipment has a high performance-to-price ratio. It has a fast return on investment through reduced labor costs and high production efficiency.Cost Effectiveness

- In addition to garlic, it can also peel onions. Customers can customize production lines to meet specific business needs.Multi-functional

Why Choose Gondor Machinery?

Gondor machinery, as a leading garlic peeling production line manufacturer and supplier, stands out in the market due to our commitment to quality, innovation, and customer satisfaction. Every staff in Gondor will make our efforts to help our customers solve their problems and provide exceptional solutions to maximize their business benefits. What’s more, Gondor machinery serves customers worldwide, and many of them consistently give us positive feedback, place repeat orders, and introduce new clients to us. Here are a few reasons why businesses prefer our machinery:

Expertise and Experience

With many years of manufacturing, designing and exporting experience in the food processing machinery, we deeply understand the unique challenges of garlic processing and have constantly improved our proccessing lines to address them effectively. For this reason, Gondor machinery can always keep the leading position in the industry.

Customization Available

Our professional designer has many years of extensive experience in mechanical design, so we can provide tailored solutions for our clients to meet their specific requirements. Thus we can guarantee that our automatic garlic peeling production line integrates seamlessly with your existing operations.

After-Sales Support

Our dedicated support team is always available online to provide after-sales support, and they can help customers resolve issues and alleviate their concerns. In addition, they are always ready to assist our clients with installation, training, and maintenance, ensuring that your production line operates smoothly.

Inclusive Product Range

With many years of manufacturing, designing and exporting experience in the food processing machinery, we deeply understand the unique challenges of garlic processing and have constantly improved our proccessing lines to address them effectively. For this reason, Gondor machinery can always keep the leading position in the industry.

Reliability and Trust

On account of consistent performance and customer satisfaction, our production lines has been trusted by clients across the globe. Many customers from Gondor group has consistently choose us for their expanding demands and their boost their business, which definitely prove the dependability and quality of our production lines.

Integration Capabilities

Our company is highly skilled at combining different machines into a seamless production line, which ensure the smooth and efficient operations, and enhance the productivity. Additionally, we help businesses achieve higher output and maintain consistent quality. Furthermore, Gondor can expand different production lines effortlessly to meet your demands.

Partner With Gondor Group

As we know, it is a smart choice for businesses to invest in our garlic peeling production line when you are looking to improve the garlic processing operation. With its high efficiency, consistent quality, and cost-effectiveness, Gondor automatic garlic peeling production line will help you achieve your production goals and maintain a competitive edge in the market. Please follow our garlic transaction news or contact us to learn more product details about our garlic peeling line and choose the right model for your business! We will help you take your garlic processing business to the next level!