Gondor Horizontal Structure Garlic Clove Separating Machine

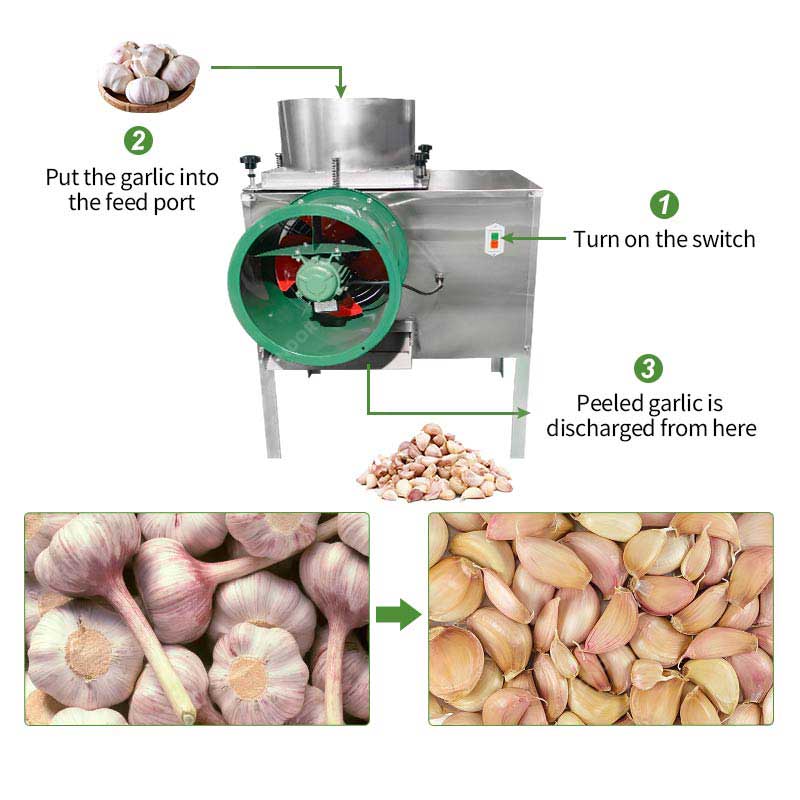

Horizontal garlic clove splitting separator is a highly efficient equipment for separating whole garlic into cloves. It employs the principle of dry rubbing, using a soft silicone disc to squeeze garlic. The silicone’s hardness is only 45 degrees, much lower than garlic’s, causing no damage. Moreover, it complies with national environmental protection and hygiene standards, suitable for various conditions like constant temperature storage, vegetable distribution and export.

Most importantly, it not only greatly improves work efficiency and reduces labor intensity but also maintains garlic clove integrity and reduces damage, facilitating subsequent deep processing like garlic slices and paste.

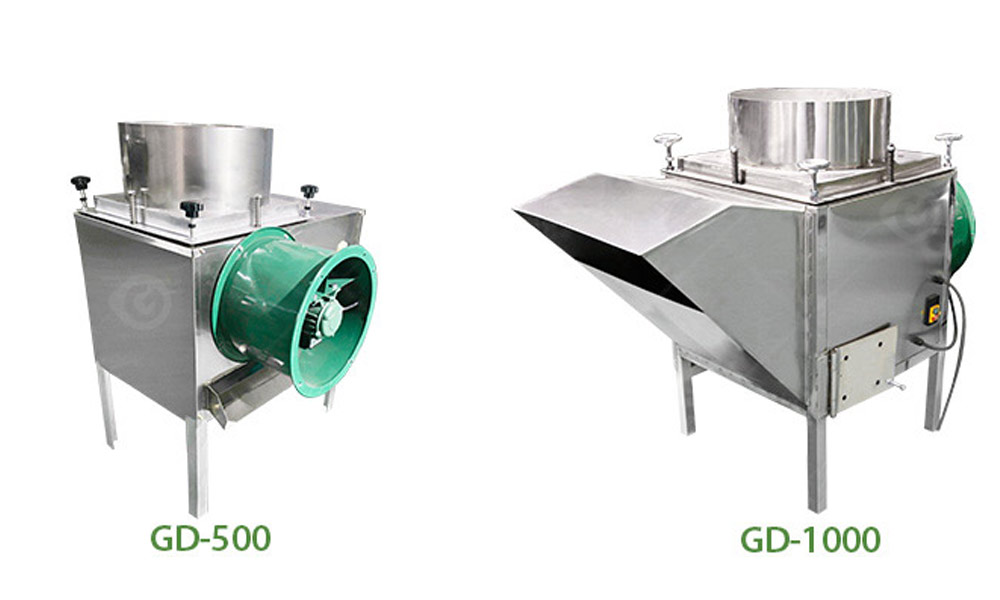

Gondor Horizontal Garlic Splitting Separator Specification

| Model | Capacity | Size | Weight |

| GD-500 | 500 kg/h | 80*74*115cm | 135kg |

| GD-1000 | 1000 kg/h | 150*73*120cm | 135kg |

Main Application Markets of the Gondor Garlic Clove Separating Machine

The garlic splitting machine efficiently processes raw materials, accurately splits the cloves to reduce damage, ensures smooth subsequent processing and improves product quality.

In order to ensure the standardization of dishes and supply efficiency, machines are used to process garlic. For example, it can meet the large demand for garlic cloves from fast food companies and save labor costs.

Split garlic seeds can improve the sowing efficiency and uniformity of garlic seed cultivation and large-scale planting. At the same time, it reduces the labor intensity of large planting households and improves planting efficiency.

When conducting garlic research experiments, the splitter provides standardized operations to ensure that the experimental data is accurate and reliable, and meet the needs of accurate splitting and processing of garlic.

Garlic traded in the wholesale market is easy to sell and transport after splitting. Wholesalers use garlic splitting machines to process, increase product added value, and can also classify and grade to meet the needs of different customers.

In the garlic import and export business, use machines to pre-process garlic to ensure that product quality meets international standards, improve packaging and transportation efficiency, and reduce costs.

Superior Advantages of the Gondor Horizontal Garlic Clove Separator

Gondor horizontal garlic splitting separator makes garlic clove separation easy and worry-free!

Dear customers, Gondor garlic splitting machine is truly your ideal choice for garlic processing. It can efficiently separates garlic cloves, thereby greatly improving production efficiency. Moreover, it has a low damage rate, ensuring the integrity of garlic cloves. Additionally, it is easy to operate, thus saving labor costs. What’s more, it has a compact structure and reliable quality, being stable and durable. So, Gondor Group garlic splitting machine to inject powerful impetus into the development of your garlic industry. Come and order it!