If you plan to enter the chili sauce market or want to optimize your existing production process, then the Gondor chili sauce production line is your ideal choice. The production line integrates the whole process automation from pepper raw material treatment to finished product filling and sterilization, and realizes “one-button production”, which not only greatly improves production efficiency but also ensures stable product quality.

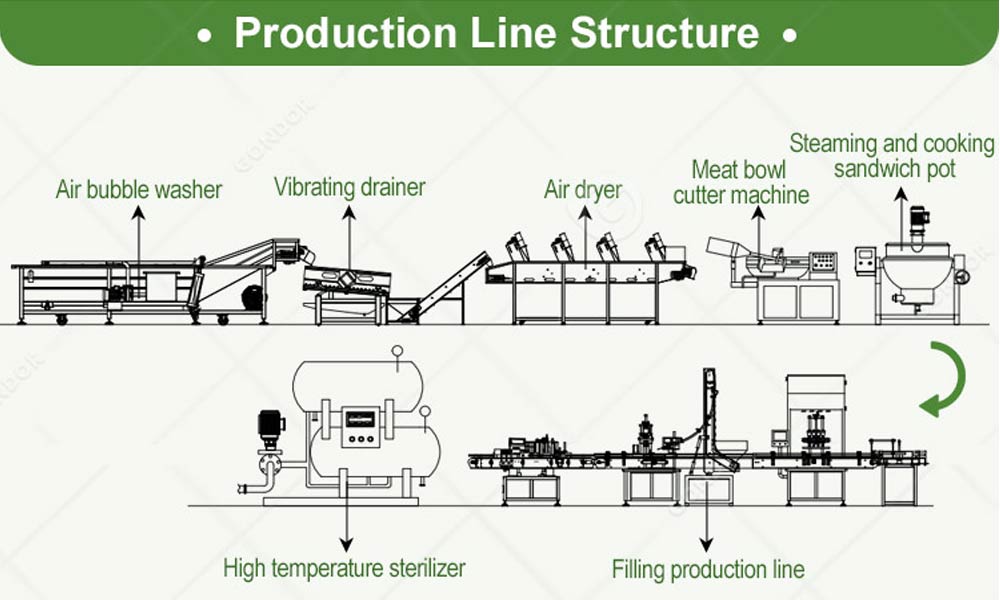

| Products | Size | Power | Voltage |

| Air Bubble Washer | 3000mm*1200mm*1300mm | 3.75kw | 380V/50hz |

| Vibrating Drainer | Customized | 0.08kw | 380V/50hz |

| Air Dryer | 4200*1200*1350mm | 0.75KW*8 | 220V/50hz |

| Meat Bowl Cutter Machine | 650mm*320mm*650mm | 3KW | 220V/50hz |

| Steaming and Cooking Sandwich Pot | 800mm*800mm*1850mm | 15kw | 220V/50hz |

| Filling Production Line | 2000mm *1100mm * 1700mm | 1.8KW | 220V/50hz |

| High-Temperature Sterilizer | 3800mm*1450mm*2700mm | 8kw | 380V/50hz |

Multi-application of Chili Sauce Production Line

Considerable Benefits and Advantages of Hot Sauce Production Line

Single-line production capacity can reach 500-1000kg/h per hour, or even higher, which can easily meet large orders and help enterprises seize market opportunities.

The whole process is automated, and only a small amount of manual labor is needed from cleaning to filling, which greatly reduces the labor cost.

The loss rate of pepper is less than 5%, which saves the cost of raw materials and improves the overall economic benefit.

The intelligent control system accurately adjusts the temperature, time, and stirring speed to ensure the consistency of each batch.

Support different types of peppers, different formulas, and taste customization, and help enterprises to create differentiated products.

The equipment is made of food-grade stainless steel, which is smooth and easy to clean and conforms to the global food safety regulations.

Modular design, convenient cleaning and maintenance, and reduced equipment downtime and maintenance costs.

The combination of high production capacity and low consumption shortens the investment recovery period and brings more considerable profit space.

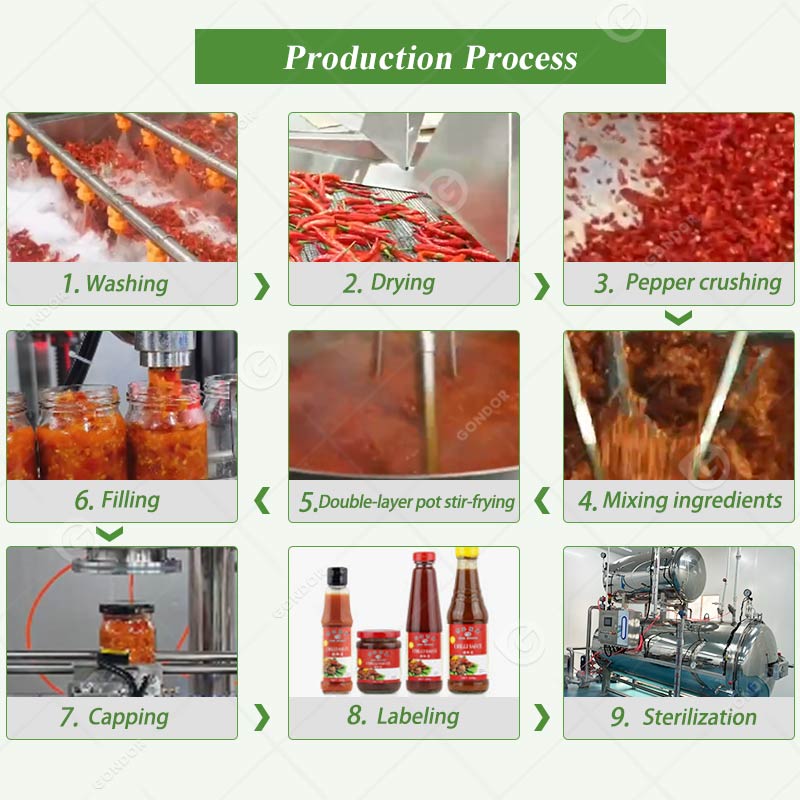

Fully Automatic Process of Sauce Production Line

As soon as fresh peppers enter the pepper lifting system, the production line is automatically completed:

- Bubble Washer Machine: Effectively removes impurities on the surface of pepper to ensure hygiene and safety.

- Vibration Dewatering Machine and Air Drying Machine: Quickly remove water and prepare for subsequent processing.

- Bowl Cutter Machine: Chop the mixed peppers at high speed to make a fine and uniform paste, keep the original color and flavor, and improve the taste of Chili sauce.

- Double Jacketed Steam Kettle: Chili sauce and seasoning are mixed in proportion, heated and boiled, and the temperature is accurately controlled to ensure the stability of flavor.

- Liquid Filling Line: according to different bottle types, the filling and sealing are accurate, with high efficiency and a loss rate below 5%.

- Retort Sterilizer: Thoroughly sterilize the finished product to ensure food safety.

- Packing System: complete the subsequent processes such as cooling, labeling, code spraying, packing, and so on.

Join Us for a Spicy Future

The chili sauce production line is not only efficient and intelligent, but also a powerful help for enterprises to create differentiated products and explore the global market. We also provide other vegetable processing equipment and other related equipment to meet your diversified production needs. Welcome to contact us, get a customized plan and detailed quotation, and let’s start a new chapter in the production of high-quality hot sauce together!