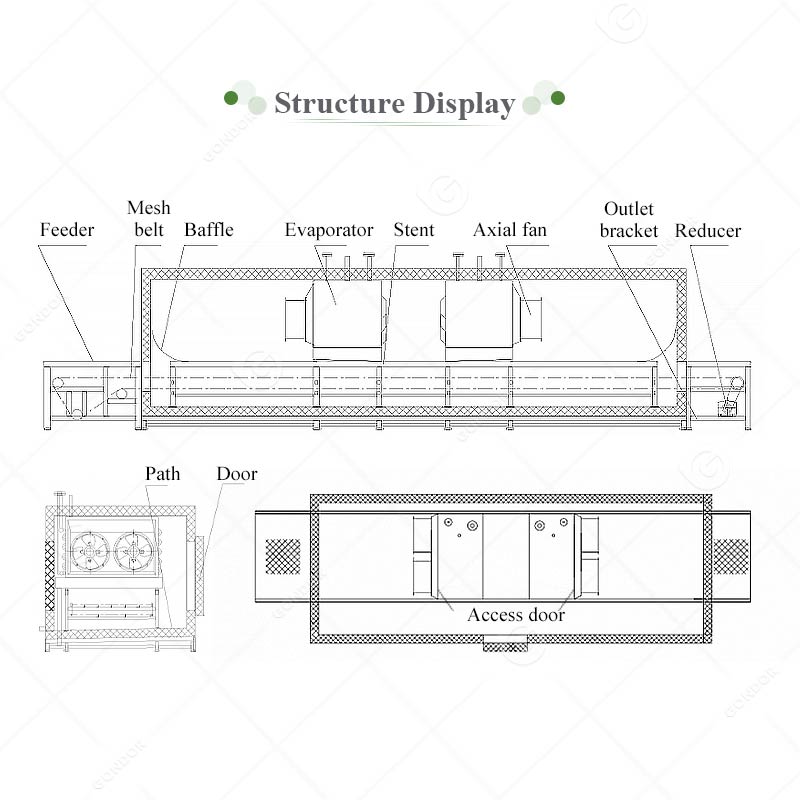

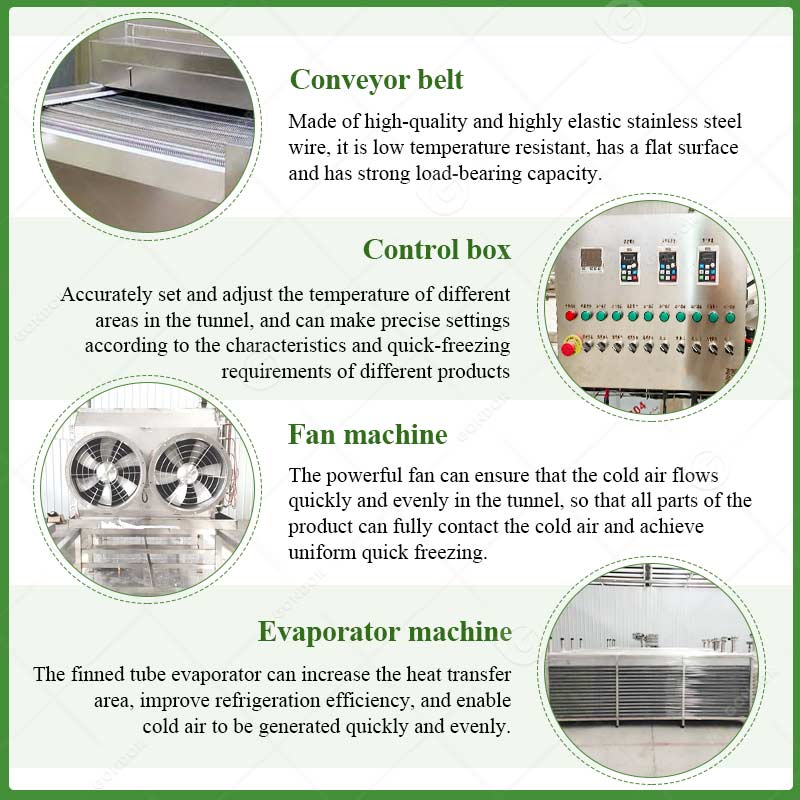

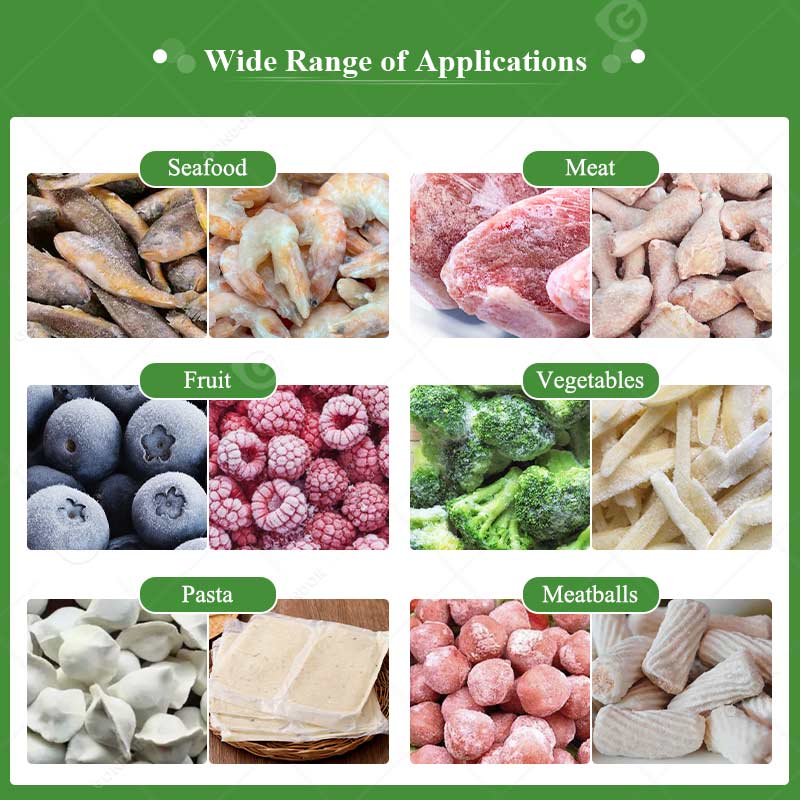

With the rapid development of the food industry, rapid freezing and efficient preservation have become the core requirements of the industry. The tunnel freezer introduced by Gondor is specially designed to meet the high standards of global customers on food quality, production efficiency, energy saving and environmental protection. The equipment adopts advanced refrigeration technology and a strong air circulation system so that the product can quickly cool down when moving at a constant speed on the conveyor belt, effectively preventing the formation of ice crystals and retaining the original flavor and nutrition to the greatest extent. It is widely used for efficient and uniform quick freezing of meat, aquatic products, fruits and vegetables, prepared foods, dairy products, and other foods, and ensures export-grade quality.

|

Model |

Freeze time | Freezing temperature | Size | Frozen product discharging temperature |

| GD-TFZM | 15-45 Minutes | -35℃ | 15500*2700*2500mm |

-18℃ |

Target Market of IQF Tunnel Freezer

Tunnel freezer is suitable for all kinds of customers around the world who want to improve the quality of food preservation, expand production capacity and optimize production process. It is especially suitable for large factories with strict requirements for continuous production.

Quickly lock in fresh food, improve food turnover, and supply chain response speed.

Kept the taste and nutrition of dishes and met the requirements of standardized production.

Quickly freeze yogurt, cheese, etc., to extend their shelf life.

Realize efficient and continuous quick freezing and ensure product quality and production efficiency.

Ensure quick freezing before transportation and ensure the freshness of the cold chain.

Significant Advantages and Highlights of Quick Freezing Machine

Open a New Era of Food Preservation

If you are looking for equipment that can be used with a tunnel freezer, such as a vegetable wash machine, packaging machine, etc., please browse our website catalogue or contact us directly for customized solutions. Let tunnel freezer become the “freezing engine” in your food processing production line, open a new era of preservation, and retain the original taste of ingredients! Our professional team of engineers will provide you with one-on-one selection suggestions and technical support to help you build an efficient, intelligent, and sustainable cold chain production system.