Gondor Marshmallow Production Line Introduction

Gondor Machinery has developed this automated cotton candy production line, combining ease of operation with ultra-high production capacity, based on cutting-edge foreign technology and localized improvements. Utilizing advanced extrusion technology and a matching formula, this marshmallows making equipment can achieve large-scale production of a variety of creative shapes, from single-color/multi-color ropes and twisted braids to watermelon shapes, animal shapes, and square shapes.

>

Gondor Marshmallow Production Line Model

We offer a variety of marshmallow manufacturing equipment specifications and can provide customized system solutions based on your production capacity targets. Contact us for a free consultation and detailed answers.

| Technical Parameter | |

| Model | GD-150 |

| Material | Stainless Steel |

| Capacity | 100-150kg/h |

| Voltage | 380v/220v |

| Marshmallow Color | As Your Request |

Application Scope and Product Forms of Gondor Marshmallow Production Line

Leveraging the high-precision extrusion control system and diverse mold solutions of our Marshmallow production line, you can effortlessly create a full range of market-leading marshmallow products that cater to the aesthetic and taste preferences of consumers across all age groups.

Standard Shapes

- Single-Color Rope: Features uniform color and delicate texture, making it a timeless favorite for bakery decoration and casual snacking.

- Multi-Color Twist: Utilizes precise multi-channel co-extrusion technology to deliver a mesmerizing spiral effect with vibrant, interlocking colors for maximum visual impact.

Innovative Designs

- Creative Watermelon Shape: Perfectly simulates a watermelon slice through intricate core-and-shell layering, serving as a seasonal bestseller.

- Bio-inspired Animal Shapes: Produces vivid, well-defined animal silhouettes using specialized molds, highly popular in the children’s confectionery market.

Geometric & Custom Series

- Four-Color Strips & Squares: Showcases clean cuts and distinct patterns, demonstrating the exceptional structural stability and cutting precision of our production line.

- Four-Strand Twist: Features exquisite craftsmanship with rich layering, significantly enhancing product recognition and premium market value.

Gondor Marshmallow Production Line Application Industries

Leverage high-capacity automation to achieve standardized mass production, ensuring a rapid response to massive orders from the global candy retail market.

Utilize flexible molds and process formulas to develop uniquely shaped, differentiated products that capture niche markets for premium snacks and specialty gifts.

Produce high-quality decorative marshmallows to provide stable ingredient sourcing and customization for cake baking, hot drink garnishes, and catering chains.

Rely on multi-color co-extrusion and precision cutting technology to offer flexible manufacturing solutions for snack brands, creating high-aesthetic, brand-exclusive products.

How to Make Twisted Marshmallows with a Machine

To make twisted marshmallows with a machine, aerated marshmallow mass in different colors is simultaneously pumped into a specialized rotating extrusion head. As the multiple colored strands are pushed through the nozzles, the head rotates at a synchronized speed to intertwine the strands into a continuous spiral rope. This twisted rope is then deposited onto a starch-coated conveyor belt, where it travels through a cooling tunnel to set its shape before being cut into uniform pieces by a high-speed synchronized guillotine.

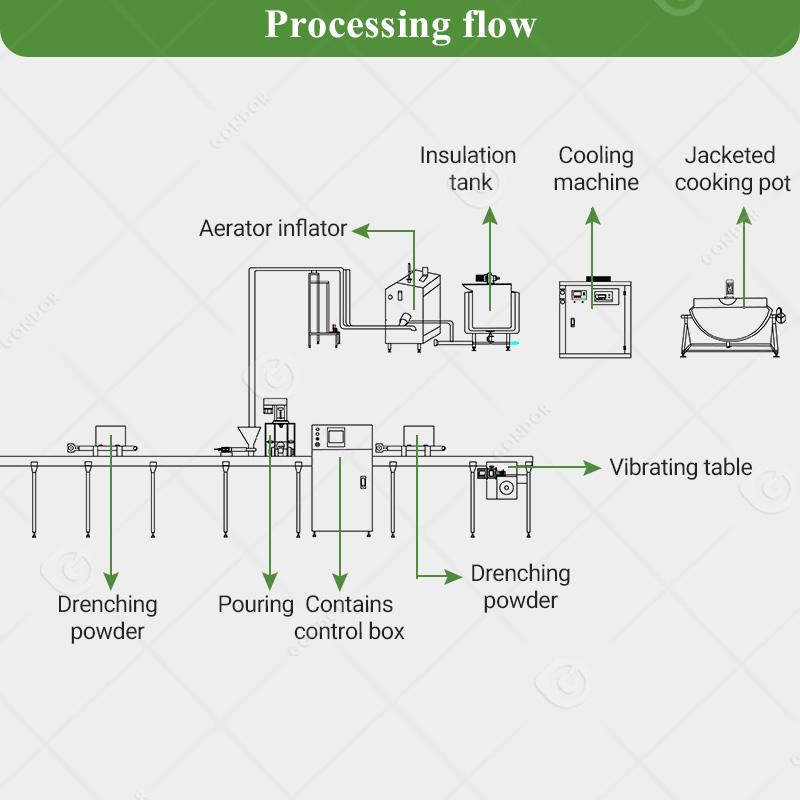

Marshmallow Production Process

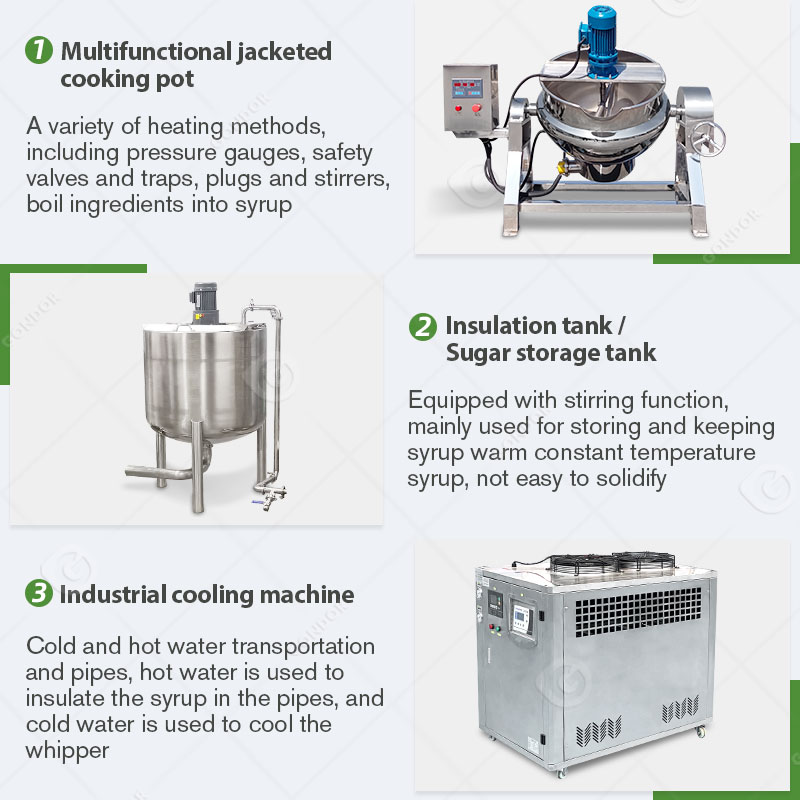

- Syrup Cooking: Ingredients are heated and boiled to precise temperatures to ensure complete dissolution and the ideal syrup consistency.

- Syrup Storage & Buffering: The cooked syrup is transferred to insulated tanks to maintain a stable working temperature, preventing premature crystallization.

- Syrup Filtration: The syrup passes through a high-efficiency filtration system to remove impurities, ensuring a smooth texture and pure quality.

- Aeration & Whipping: The core stage where air is whipped into the syrup at high speeds, transforming the dense mixture into a light, fluffy, and aerated mass.

- Shaping (Extrusion / Depositing): The aerated mass is either extruded through nozzles or deposited into molds to create various shapes like twists, watermelons, or animals.

- Starch Coating: A fine layer of starch or sugar is evenly applied to the surface to prevent sticking and give the marshmallow its signature dry finish.

- Vibratory Sifting & Discharge: The finished pieces move across a vibratory screen to remove excess powder, ensuring clean products ready for final packaging.

Marshmallow Production Line Features

Small footprint with simple operation, designed for high-efficiency industrial output.

Switch components to produce multicolored strips, blocks, or jam/chocolate-filled marshmallows.

A complete automated system covering boiling, aeration, mixing and extrusion.