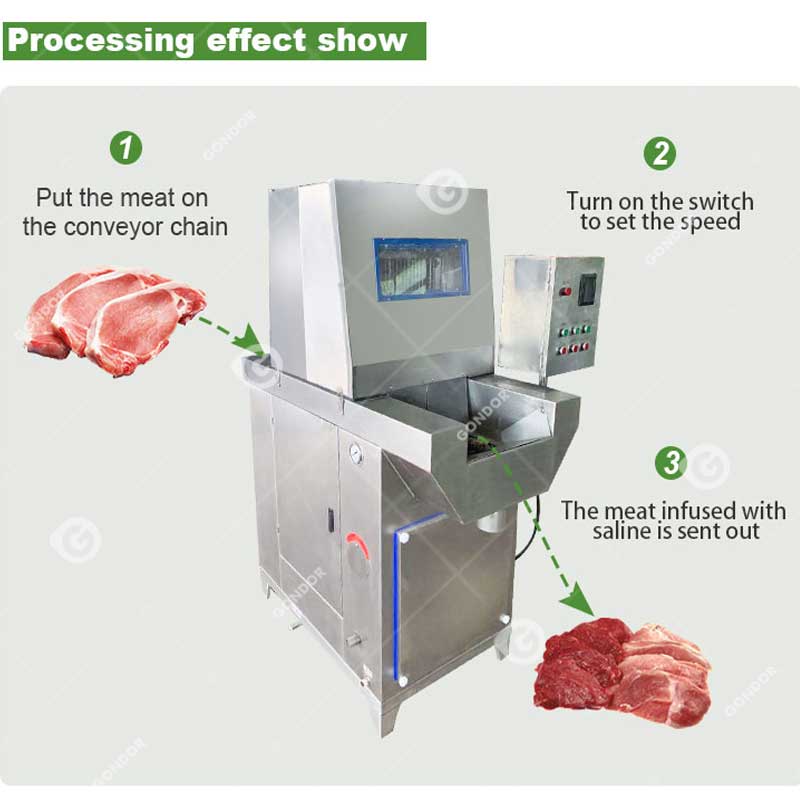

Precision Brine Injection for Enhanced Meat Quality

The meat saline brine injector machine is an essential piece of equipment in modern meat processing operations, playing a crucial role in improving product quality and production efficiency. Its primary function is to uniformly inject prepared brine solutions, pickling agents, or seasoning liquids deep into the meat tissue. Utilizing an array of fine needles operating under controlled pressure, the machine rapidly distributes the liquid throughout the meat fibers. What’s more, this process not only enhances the meat’s tenderness and juiciness but also significantly accelerates the pickling process compared to traditional immersion methods, allowing for faster production cycles and consistent flavor penetration.

| Model | Power | Capacity | Injection | Voltage | Injection speed | Machine size |

| ZYZ-48 | 4.1kw | 300kg | 0.45-0.9Mpa | 380v | 40-70m/min | 1350x750x1650mm |

| ZYZ-80 | 5.1kw | 700kg | 0.45-0.9Mpa | 380v | 40-70m/min | 1550x880x1650mm |

| ZYZ-120 | 6.2kw | 900kg | 0.45-0.9Mpa | 380v | 40-70m/min | 1850x1350x1800mm |

Applicable Industries of Gondor Meat Injector Machine

- Such as ham, sausage, etc., through brine injection, the meat is more tender and juicy, and the pickling process is accelerated.Meat Product Manufacturers

- Pre-process the cut meat to prepare for subsequent processing.Large Slaughterhouses

- Produce products such as prepared chicken and prepared beef, injecting brine to improve taste and flavor.Prepared Food Production Plants

- Provide standardized semi-finished food ingredients for chain catering companies, and brine injection can ensure the consistency of food quality.Central Kitchen

- Central kitchen, providing meat ingredients treated with brine injection for its stores, facilitating store cooking and making dishes.Catering Service Industry

- Meet the requirements of foreign markets for product quality and taste, and brine injection can enhance product competitiveness.Export Food Companies

- Used for experimental research and teaching demonstrations, to explore the impact of brine injection on meat quality and optimize processing technology.Teaching Fields

Unique Performance Characteristics of Gondor Saline Injection Machine

Easy operation, high degree of automation, reduced manual intervention, reduced labor intensity, and also improved the standardization of production.

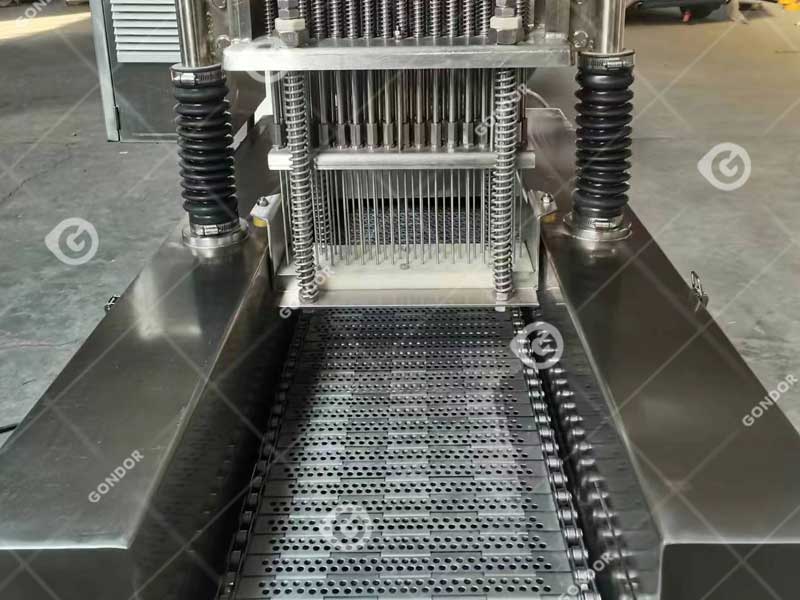

The four-level layered filtration function can filter out the particles in the liquid in time, effectively ensuring that the injection needle hole is not blocked.

Using PLC controller, the chain step and step speed can be adjusted synchronously with the needle speed.

It can accurately control the injection volume and injection depth of brine to ensure that each piece of meat can evenly absorb the brine and achieve the best pickling effect.

The parts in contact with food are made of stainless steel and other materials that meet food hygiene standards, which are corrosion-resistant, easy to clean, and will not cause pollution to meat.

The injection needle adopts a single needle and a single tube, and the injection is uniform. The independent spring design can automatically rebound when encountering hard objects.

It is not only suitable for common meats such as pork, beef, and mutton, but also can be used for saline injection of various poultry and aquatic products to meet diverse processing needs.

Upstream and Downstream Related Equipment

The brine injector machine can efficiently collaborate with the following equipment to form a meat processing production line:

Pre-processing Equipment:

- Frozen Meat Mincer: Directly conveys the injected meat to the grinder, achieving continuous operation of marinating and mincing.

- Vacuum Meat Tumbler: After injection, the tumbling process ensures uniform penetration of brine, improving meat tenderness and flavor integration.

Downstream Processing Equipment:

- Meat Mixer Machine: Suitable for products such as sausages and meatballs, it mixes the injected meat with auxiliary materials to ensure consistent seasoning.

- Smoking Oven/Cooking Line: Marinated meat products can directly enter the cooking process, forming a seamless automated process.

Frequently Asked Questions

Meat Saline Brine Injector Machine – Gondor Group Manufacturer

Choose Gondor meat saline brine injector machine to improve the quality of your meat processing! Our meat injector machine is accurate and efficient, making every piece of meat evenly flavored. Besides, its easy operation, stable performance, and high-quality after-sales service can give you peace of mind. Buy now to add competitiveness to your products! Join hands with Gondor to create a delicious future!