Efficient Automatic Paper Cup Making Machine

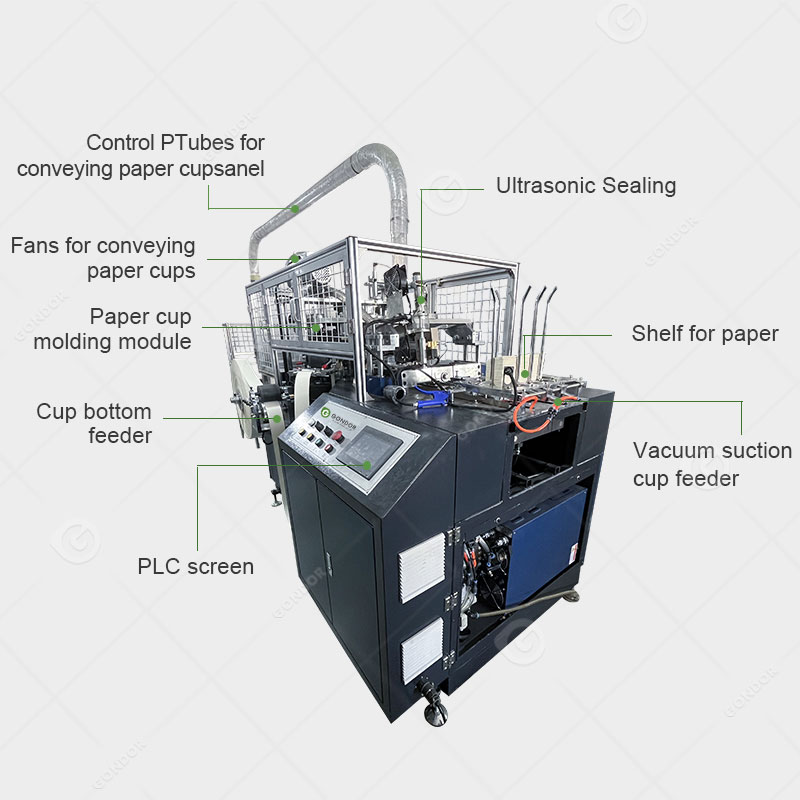

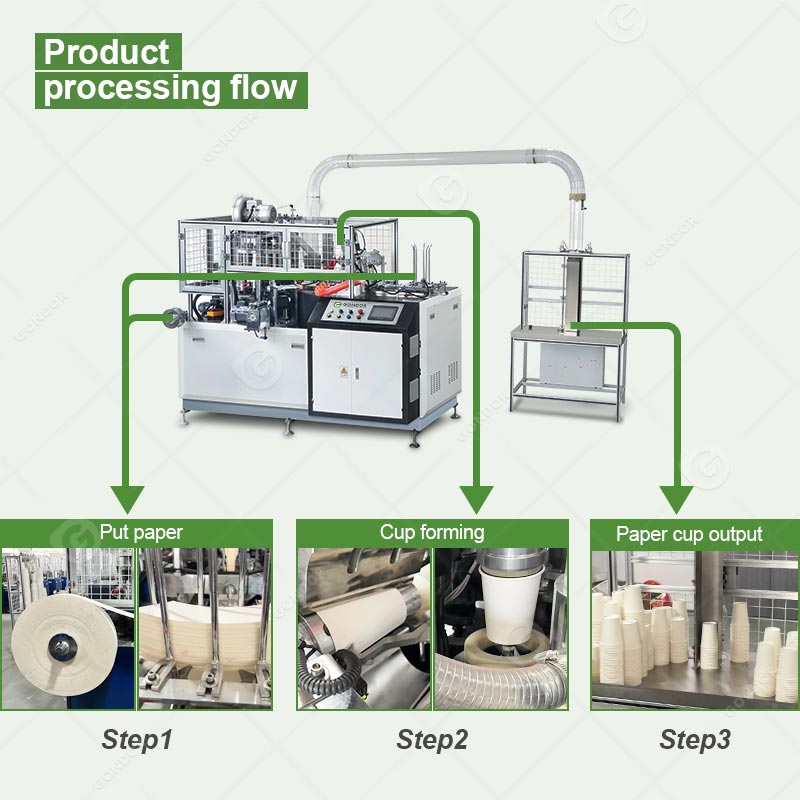

Paper cup glass making machine is a highly integrated multi-station automatic forming machine, which realizes efficient production through a series of precise and coordinated continuous processes, including key steps such as automatic paper feeding, heat sealing, oiling, bottom punching, knurling, curling and automatic collection of finished products. In addition, the equipment is equipped with advanced photoelectric detection system, real-time fault alarm device and production counting function to ensure the stability and controllability of the production process. More importantly, Gondor paper cup machine not only has excellent operating efficiency and stable output performance, but also can flexibly adapt to the production requirements of various specifications and shapes of paper cups.

At the same time, the design of the equipment fully considers the convenience of user operation, and its high level of automation significantly improves the overall production efficiency and effectively reduces the labor and time costs. Whether it is a large-scale food and beverage enterprise or a small and medium-sized catering supplier, Gondor paper cup machine can provide strong support for the growing market demand with reliable performance and adaptability, and help enterprises realize large-scale and standardized production.

| Name | Paper cup making machine | |

| Model | GD-S800 | GD-M100 |

| Power | 6kw | 4.5kw |

| Weight range of paper cup | 16oz | 1.5-9oz |

| Working Air Source | 0.4-0.6Mpa; 0.4m³/min | |

| Paper weight | 160-300g/m²;±20g/m² | |

| Output | 40-60 pcs/min | 90-110pcs/min |

| Cup size | Bottom 35-70mm;Top 45-90mm; Height 32-135mm |

Bottom 28-54mm;Top 40-75mm; Height 30-95mm |

| Paper Material Requirements | Single and double laminated paper | |

| Size of main machine | 2100*1200*1800mm | 1900*875*1550mm |

| Size of shelf | 900*600*1500mm | 900*600*1500mm |

| Weight | 2000kg | 1500kg |

| Cup Side Sealing | Ultrasonic | |

| Bottom Knurling | HOT AIR SYETEM | |

Wide Application Market Range of Gondor Paper Cup Making Machine

Paper cups with different beverage capacities and styles can meet the personalized needs of coffee shops and milk tea shops, helping the shops to create a unique brand image.

Restaurants also use paper cups when providing drinks such as water and juice. Paper cups with reliable quality and exquisite appearance add a sense of quality to the restaurant.

Customized production of paper cups of different specifications and patterns, perfect match with beverage packaging production line, improve production efficiency and reduce packaging costs.

Many companies will customize the production of paper cups with corporate logos and advertising information to expand the influence of corporate brands. It is a low-cost, high-exposure publicity method.

The paper cup machine can quickly produce customized paper cups, print exhibition information and sponsor logos, and enhance the overall image of the exhibition.

At event sites such as concerts and sports events, the Gondor paper cup machine can meet the paper cup needs of the event in a timely manner to ensure the smooth progress of the event.

Outstanding Equipment Features of Gondor Paper Glass Machine

- Continuous production of paper cups improves production efficiency and meets the production needs of large-scale orders.High-speed Operation

- The entire production process is basically automated, reducing manual intervention and labor intensity.High Degree of Automation

- Paper cups with regular shapes and smooth edges not only improve the appearance quality, but also facilitate subsequent packaging and use.Accurate Size

- Through precise molds and control systems, paper cups that meet standard requirements are produced.Regular Shape

- The vacuum adsorption transmission device automatically transmits the printed fan-shaped paper forward.Automatic Transmission

- Equipped with PLC display, supports multiple languages, simple and easy to use.Intelligent System

- It is easy to adjust the parameters and molds of the equipment to meet diverse production needs.Convenient Adjustment

- There are complete safety protection devices, such as external guardrails, emergency stop buttons, etc., to ensure the safety of operators.Safety Protection

Gondor Paper Cup Glass Making Machine – Your Professional Paper Cup Production Partner

Our paper cup machine is the core weapon of efficient automatic production, which can be accurately molded and run at high speed, and easily meet the needs of food packaging, beverage take-out and enterprise customization. With our paper bowl making machine, we can realize the flexible production combination of cups and bowls and enrich your product line. It can also be seamlessly connected with pillow packaging machine to form an integrated production line of “production-packaging”, which greatly improves the terminal processing efficiency. Choosing Gondor means choosing systematic solutions, excellent quality and lasting efficiency, ordering immediately and opening a new chapter in your paper products production!