Gondor Pasta Production Lines

In today’s era of pursuing quality and personalized consumption, small food workshops and entrepreneurs are constantly looking for production equipment that can balance technology, efficiency, and taste. Our brand-new small pasta production line was born for this purpose. It combines traditional Italian noodle-making technology with modern automation technology, making it easy for your workshop to replicate authentic Italian flavor and create a competitive local food brand.

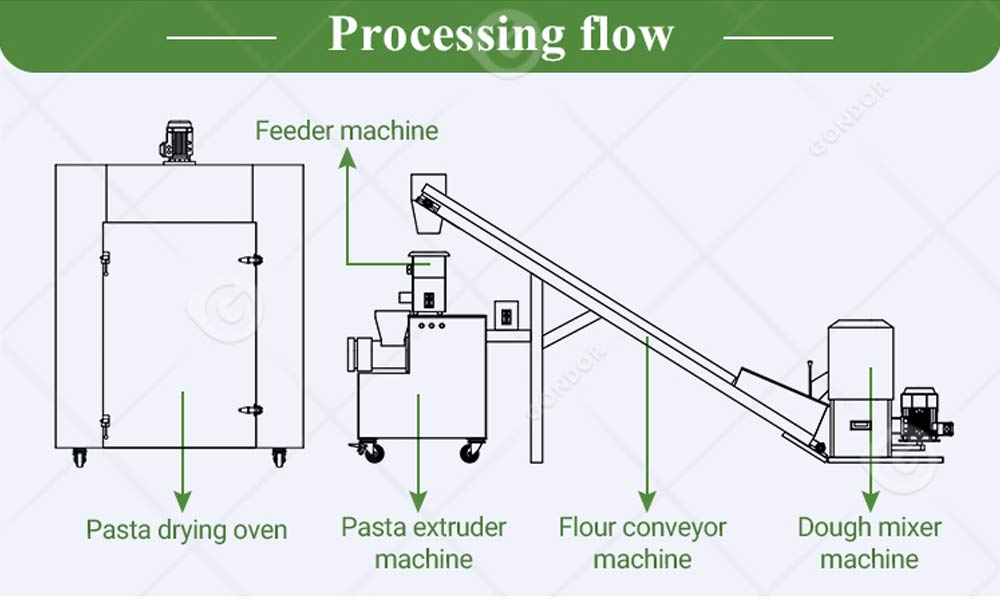

This semi-automatic macaroni production line is specially designed for small and medium-sized food enterprises, central kitchens, and startup workshops. The entire line consists of a dough mixer, flour conveyor, feeding system, macaroni extruder, and drying machine. The equipment features a compact structure, small footprint, and easy operation, supporting various molds and customizable production capacities to achieve fully automated production from raw materials to finished products.

Small Pasta Production Line Specification

| Machine Name | Voltage | Power | Material | Size |

| Dough mixer machine | 380V | 3kw | Stainless steel | 900*550*1000mm |

| Flour conveyor machine | 220V | 0.35kw | 2800*750*650mm | |

| Pasta extruder machine | 380V | 5.5kw | 1100*650*1200mm | |

| Pasta drying oven | 380V | 12kw | 1400*1250:2350mm | |

| Feeder machine | 220V | 0.3kw | 650*420*450mm |

Target Market of Long Cut Pasta Production Line

Long cut pasta production line is an ideal choice for small and medium-sized food manufacturers around the world, especially for the following customer groups:

Help brands differentiate their Italian flavor in the local market.

An ideal equipment scheme with low investment and high return.

Used to develop short pasta products with innovative shapes and flavors.

Meet the demand of fresh noodle making on-site and enhance the customer experience.

Core Equipment Characteristics of Short Cut Pasta Production Line

Unique Advantages of a Small Pasta Production Line

Help to Create Authentic Italian Flavor

If you are planning a complete pasta processing project, we also provide a variety of supporting equipment:

- Dry Pasta Macaroni Production Line

- Pasta Packing Machine

- Vacuum Kneading Machine

- Continuous Dryer