Gondor Vegetable Air Dryer Machine

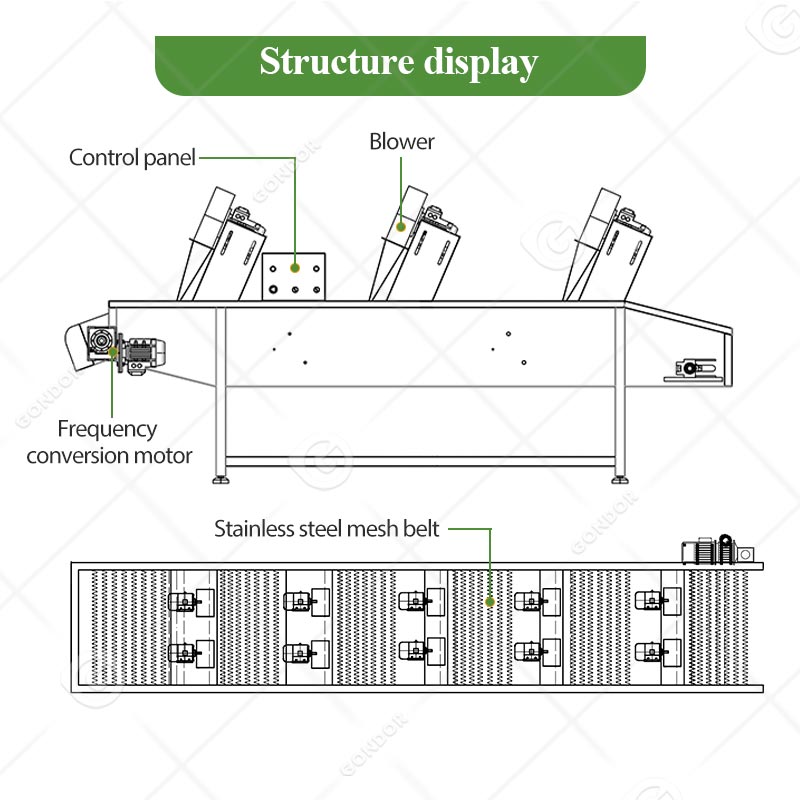

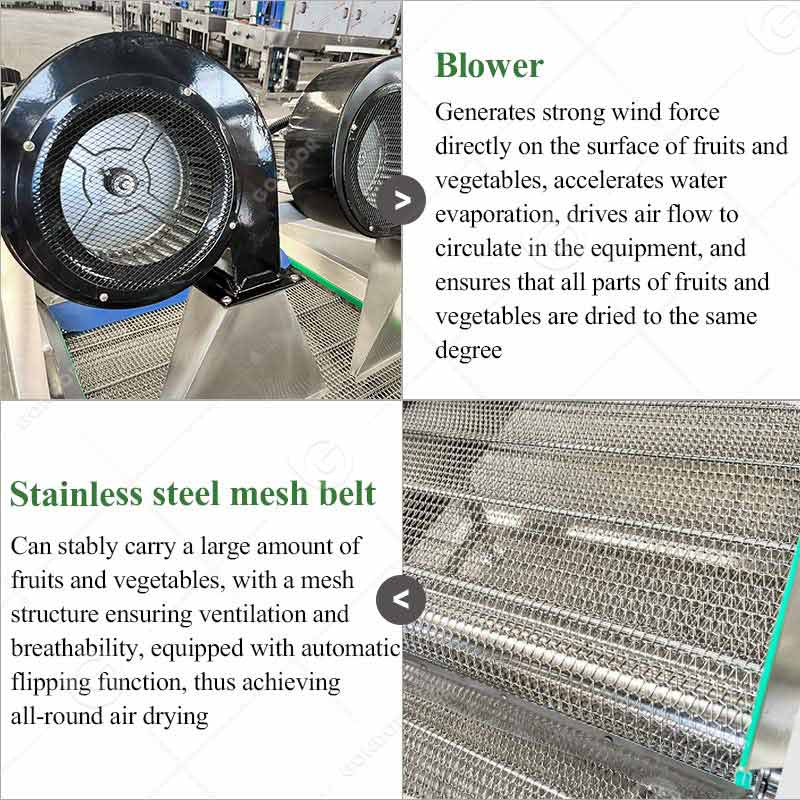

In modern food processing, because the packaging and storage will be affected if the cleaned materials are not dehydrated in time, the Gondor vegetable air drying machine came into being. It can quickly dry the water droplets on the surface within 30 seconds, thus greatly improving the efficiency. The equipment adopts several low-noise fans to form a three-dimensional air supply system and realizes all-around water removal through normal temperature air.

In addition, it is equipped with an automatic turning and adjustable speed conveying motor, which is simple to operate, highly efficient, and stable in performance. The whole machine is made of food-grade stainless steel, so it is durable and meets international food safety standards.

Vegetable Air Drying Machine Specifications

|

Model |

Size | Power(kw) | Capacity(kg/h) | Qty of fan(piece) |

Mesh belt width(mm) |

| GD-CADM-300 | 3000*1250*1300 | 4.5 | 500-800 | 6 | 800 |

| GD-CADM-400 | 4000*1250*1300 | 10.1 | 800-1200 | 8 | |

| GD-CADM-500 | 5000*1250*1300 | 13.6 | 1200-1500 | 10 | |

| GD-CADM-600 | 6000*1250*1300 | 16.6 | 1500-1800 | 12 | |

| GD-CADM-700 | 7000*1250*1300 | 18.6 | 1800-2000 | 14 | |

| GD-CADM-800 | 8000*1250*1300 | 20 | 2000-2500 | 16 | |

| Notes: The air drying machine can be customized according to the requirement, including the capacity, size, brand, fans, etc. | |||||

Scope of Use of Vegetable Air Dryer

Vegetable air dryers play a key role in many industries:

Core Advantages of the Food Cooling Machine

Create a Complete Processing Line

To form a complete processing line, in addition to the air drying machine, we also provide the following related equipment:

- Vegetable Washing Machine

- Packaging Machine

- Sterilizing Equipment

- Labeling Machine

Feel free to contact us for the complete line solution. We support OEM/ODM customization to help you build an intelligent factory! Whether you are a small processing enterprise or a large factory, we can provide the most suitable air drying solution!

Gondor Vegetable Air Drying Machine FAQs

1) What problem does this Vegetable Air Drying Machine primarily solve?

A: It is mainly used to quickly dry water droplets on the surface of washed materials or packaging, preventing residual water from affecting subsequent packaging sealing, storage, and quality safety, thereby improving production line efficiency and extending shelf life.

2) Is it a “heated drying” or “room temperature air drying” machine?

A: This equipment uses room temperature air for drying, without heating to evaporate moisture, which better protects the color and taste of the materials; the page also indicates a temperature range of approximately 26–40℃.

3) How fast is the drying speed?

A: The page states that it can quickly blow away water droplets on the surface of materials in approximately 30 seconds (actual speed will vary depending on the shape of the material, its moisture content, and the thickness of the layer).

4) Which products/industries is it suitable for?

A: Commonly used in food processing and deep processing of agricultural products, such as dehydration of bagged foods, fruits and vegetables, and jellies before packaging; also suitable for initial processing of agricultural and aquatic products, cleaning of medicinal materials or packaging materials, pretreatment of dairy product containers, dehydration of bottle/raw material surfaces before sauce filling, and rapid air drying of meat products after cleaning/sterilization.

5) How are the machine’s materials and food safety guaranteed? Is it easy to clean?

A: The entire machine is made of SUS304 food-grade stainless steel, which is rust-proof, corrosion-resistant, and easy to clean, meeting hygiene requirements and food safety standards. The page also lists multiple certifications (such as ISO, CE, etc.).