Paraguay'a Bisküvi ve Ekmek Ekipmanları İhraç Edildi, Marka Otomasyonu Yükseltmelerini Kolaylaştırma

Güney Amerika'nın fırıncılık endüstrisinde, Paraguaylı bir şirket, üstün ürün kalitesini kullanarak, yalnızca yerel pazarda lider konumunu güvence altına almakla kalmadı, aynı zamanda Kuzey Amerika'ya da yayıldı, Kendi markasını ve istikrarlı bir satış ağını kurmak.

Pazar talebi artmaya devam ettikçe, geleneksel manuel ve yarı otomatik üretim yöntemleri artık gelişen ihtiyaçları karşılayamıyor. Otomasyon çözümleri arıyorum, müşteri Gondor Machinery'ye döndü. Deneyimli Paraguaylı fırın sahiplerine özelleştirilmiş gıda makineleri çözümlerini başarıyla sağladık, yüksek performans dahil bisküvi makineleri, ekmek dilimleyiciler, ve ekmek ruloları.

Müşteri İhtiyaçları: Miktardan ziyade Kalite

Müşterinin ana ürünleri kurabiyeler ve galetalardır. Şu anda çeşitli üretim zorluklarıyla karşı karşıyalar:

- 1. Galeta kesme boyutu ve uzunluğunda tutarlılığın korunması zordur, Ambalajı ve ürün stabilitesini etkileyen.

- 2. Galeta yuvarlama işlemi büyük ölçüde operatörün becerisine bağlıdır; yeni çalışanlar yavaş öğreniyor, getiri oranlarında dalgalanmalara yol açıyor.

- 3. Kurabiye oluşturma ve çıktı ritimleri el emeğinden önemli ölçüde etkilenir, yoğun sezonlarda önemli teslimat baskısına neden olur.

İlk iletişimde, müşteri tipik bir davranış sergiledi “uzman alıcı” özellikler. Açıkça belirttiler, “Tek amacım nicelik değil; ürünün şekillendirme etkisi ve makinenin dayanıklılığı çok önemlidir.” Daha sonra ihtiyaçlarını sıraladılar:

- 1. Bisküvi Üretim Çeşitliliği: Müşteri çok çeşitli çerezler üretir, Sadece hassas ekstrüzyon kapasitesine sahip değil, aynı zamanda değişen viskozitelerdeki hamurlara da uyum sağlayabilen makineler gerektirir, Sıkı Kuzey Amerika ihracat standartlarını karşılamak için her çerez için tutarlı ağırlık ve görünüm sağlanması.

- 2. Galeta Dilimleyici: Temiz ve hassas kesim gerekiyor, eşit kenarlar, hamurun yapısını korumak.

- 3. Galeta Rulosu: Bitmiş üründe pürüzsüz bir yüzey ve uygun iç yoğunluk sağlamak için elle yoğurma basıncını simüle eder.

Güven Oluşturmak: CE Sertifikası ve Profesyonel Teknik Destek

Paraguaylı müşterimiz için, Uluslararası büyük makine satın alırken en büyük endişeler kalite uyumluluğu ve satış sonrası hizmettir.

Müşteriye gerekli tüm sertifikaları sağladık, ve müşteri bize olan güvenini ifade etti, Tesisimizi ziyaret etmeye karar vermek.

Şüpheleri Ortadan Kaldırmak: CE Sertifikasının Onaylanması

Müşterinin ürünleri Kuzey Amerika'da satıldığı için, üretim ortamları ve ekipmanları uluslararası güvenlik ve hijyen standartlarını karşılamalıdır. Müşterinin kaliteyle ilgili endişelerini gidermek, CE sertifikası sağladık (Avrupa Uygunluğu) tüm üretim hattına ilişkin belgeler.

Emniyet: Ekipmanın devre koruması ve mekanik güvenlik tasarımı Avrupa güvenlik yönetmeliklerine uygundur.

Hijyen Standartları: Makinenin gıdayla temas eden tüm parçaları gıdaya uygun paslanmaz çelikten yapılmıştır (SUS304), temizlik ve dezenfeksiyonu kolaylaştırır.

Fabrika ve Showroom Ziyareti, Sonuçları Onaylamak için Yerinde Test

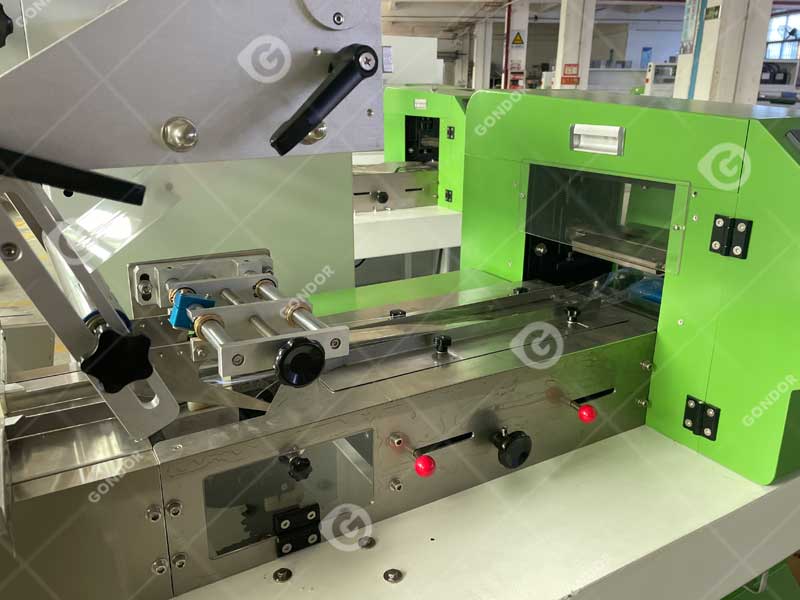

Ekipmanın spesifik üretim süreçlerini tam olarak karşılamasını sağlamak, müşteri, Gondor Makinelerinin yerinde incelenmesi için şahsen Çin'e uçtu. Bu ziyaret projenin nihai uygulanmasında önemli bir dönüm noktası oldu.

1. Şeffaf Üretim Süreci Gösterimi

Mühendisler eşliğinde, müşteri atölyeyi gezdi, İki çekirdekli makinenin üretim süreçlerinin ayrıntılı olarak anlaşılması. Hammadde kesme ve kaynaklamadan temel bileşen markalarının seçimine kadar, müşteri Gondor'un detaylara olan bağlılığına ilk elden tanık oldu.

2. Yerinde Test: Veriler ve Bitmiş Ürünler Kendi Adına Konuşuyor

Müşteri markasına özel formülünü getirdi, ve showroom'da yerinde testler gerçekleştirdik:

3. Kurabiye Makinesi Testi: Kalıpları ayarladıktan sonra, makine hızlı bir şekilde mükemmel şekilli kurabiye hamuru parçaları üretti, minimum aralıkta kontrol edilen kalınlık hataları ile.

4. Hamur Açma Bağlantı Testi: Müşteri, ekmek şeritleri kesildikten sonra açma makinesine giren hamurun düzgünlüğünü gözlemlemeye odaklandı. Test, otomatik bağlantının manuel hareketten kaynaklanan hamur deformasyonunu etkili bir şekilde önlediğini kanıtladı.

Müşteri geri bildirimi: “Makinenin çalışma sırasında stabilitesini gözlemledim; titreşim minimum düzeydeydi, ve gürültü kontrolü mükemmeldi. Bu, iç dişlilerin ve motorun çok hassas bir şekilde eşleştiğini gösterir.”

Ziyaret ve deneme çalışması sayesinde, müşteri, ekipmanın çalışma mantığına dair sezgisel bir güven kazandı, istikrar, ve kontrol edilebilirlik, ayrıca satın alma kararlarını teyit etmek.

Takip Gelişmeleri: Paketleme Ekipmanı Eklemeyi Planlıyoruz

Fabrikayı ve showroomu ziyaret ettikten sonra, müşteri genel otomasyon yükseltmelerine daha fazla ilgi gösterdi, özellikle gelişmiş seviyemize çekildi yastık paketleme makinesi ve otomatik paketleme hattı. Önceden, müşterinin paketleme süreci büyük ölçüde manuel emeğe dayanıyordu, ancak Gondor paketleme makinesinin bisküvi üretim hattına ne kadar kusursuz bir şekilde entegre olduğunu gördükten sonra, müşteri daha fazla maliyet azaltma potansiyelinin farkına vardı.

Ürünleri Kuzey Amerika pazarında satıldığı için, paketleme tutarlılığı ve verimliliği konusunda daha yüksek gereksinimlere sahipler. Müşteri, paketleme ekipmanının daha fazla yapılandırılmasıyla ilgilendiğini ifade etti, ve her iki taraf da şu anda belirli ambalaj formatları gibi ayrıntıları tartışıyor, çanta tipi gereksinimleri, ve entegrasyon yöntemleri.

Şu anda, her iki taraf da paketleme makinesinin özelleştirilmiş özelliklerine ilişkin derinlemesine görüşmelerde bulunuyor, film malzemesi uyumluluğu, Paraguay'da voltaj uyumluluğu.

Paraguaylı bir müşteri neden Gondor Machinery'yi seçti??

Oldukça rekabetçi bir küresel pazarda, müşteri sonuçta birkaç önemli nedenden dolayı sipariş verdi: