In today’s food processing industry, it is essential for businesses to focus on enhancing production efficiency and maintaining product quality to achieve success. Recognizing this, Gondor Machinery, a pioneer focused on providing high-efficiency food processing equipment, has recently partnered with a coffee chain in Qatar. This collaboration involves delivering customized commercial peanut butter making machines, which are designed to support the chain’s new product development. By integrating advanced technology and tailored solutions, Gondor aims to enhance the coffee chain’s market competitiveness, which ensures it can meet the evolving consumer demands while optimizing their production processes. This partnership not only highlights Gondor’s commitment to innovation but also showcases the potential for growth in the food processing sector through strategic collaborations.

Gondor Commercial Peanut Butter Making Machine

Project Overview: Customized Peanut Butter Production Line

Our client from Qatar, who has a decade of experience in the food industry and currently operates 15 coffee shops, is dedicated to driving brand innovation. Therefore, on August 1, 2024, they reached out to us with inquiries regarding customized equipment. After a month of productive communication, they ultimately placed an order on September 5th. Their goal is to attract a broader consumer base by launching a diverse range of nut chocolate spreads. Notably, this new peanut butter product line not only enriches its menu but also has the potential to significantly enhance overall store sales.

In order to achieve these objectives, the Qatari client has outlined specific requirements for their commercial peanut butter making machines. During our communication, we found that they need a capacity of 50 kg/h peanut butter production line, with a strong emphasis on equipment adaptability, product quality, and production safety. Furthermore, they are seeking an efficient production line that will ensure consistent product quality and flavor. At the same time, they are looking forward to minimizing human factors that could impact overall quality. By addressing these requirements, they will be well-positioned to improve their market competitiveness and meet the evolving demands of consumers.

Factory Visit – Client from Qatar

Lunch Communication with Qatari Client

Project Goals: Commercial Peanut Butter Making Machine in Qatar

The primary goal of this collaboration with our client from Qatar is to enhance production efficiency and ensure that the peanut butter production line can consistently and effectively produce nut chocolate spreads for our customer’s coffee shops. Through our focused efforts, we aim to meet the client’s expectations and strengthen their market competitiveness. For this reason, we are particularly focused on several key aspects below to achieve success:

Machine Compatibility

Ensuring seamless integration between all equipment is essential for facilitating a smooth production process and minimizing downtime as much as possible.

Quality Control

We will ensure that each piece of food processing equipment meets its quality standards while implementing a rigorous quality inspection mechanism throughout the production process.

Production Safety

By adhering to industry best practices, we strive to guarantee the safe operation of all machines in commercial peanut butter making machines, thereby reducing production risks.

Communication Process with Qatari Coffee Chain Client

In our communication with the client from the Qatari coffee chain, we implemented a series of specific measures to ensure a comprehensive understanding of their needs and to provide tailored solutions. Below is a detailed overview of the process based on actual case information:

Key Equipment Overview of Commercial Peanut Butter Making Machines

Commercial Peanut Roasting Machine

This essential equipment plays a critical role in the peanut butter production line by evenly heating nuts, which not only enhances their unique flavors but also minimizes nutritional losses during processing. With its precise temperature control, the peanut roasting machine ensures optimal taste in every batch, thereby establishing a solid foundation for product quality.Peanut Butter Grinding Making Machine

The peanut butter grinding machine is designed with high efficiency and precision, ensuring a smooth and consistent texture. With its powerful motor and advanced grinding mechanism, the grinding machine for peanut butter effortlessly processes peanuts into fine, creamy butter. Additionally, the machine is equipped with adjustable settings, allowing for customization of the grinding texture, which makes it ideal for producing not only peanut butter but also other nut-based spreads.Chocolate Tempering Melting Machine

This chocolate tempering and melting machine boasts a dual melting tank design, which ensures even chocolate melting while providing precise temperature control. Moreover, its efficient pouring function not only enhances production efficiency but also improves the visual appeal of the products, which makes it an ideal choice for various chocolate-making applications.Chocolate Mixing Tank

The chocolate mixing tank is a crucial component in the chocolate production process, which is designed to evenly blend ingredients and maintain a consistent texture. With advanced temperature control systems, it ensures the chocolate remains smooth while preventing any unwanted crystallization. Ideal for large-scale or artisanal chocolate production, it enhances product quality and efficiency.Double Head Paste Filling Machine

The double head paste filling machine is designed for efficient and precise filling of various paste-like substances. Equipped with two filling nozzles, it ensures high-speed production while maintaining accuracy. Moreover, the machine’s adjustable settings allow for flexible filling volumes, making it ideal for a wide range of industries, from food to cosmetics. Its user-friendly interface and easy-to-clean components further enhance its practicality and efficiency in daily operations.Desktop Capping Machine & Automatic Sealing Machine & Round bottle label machine

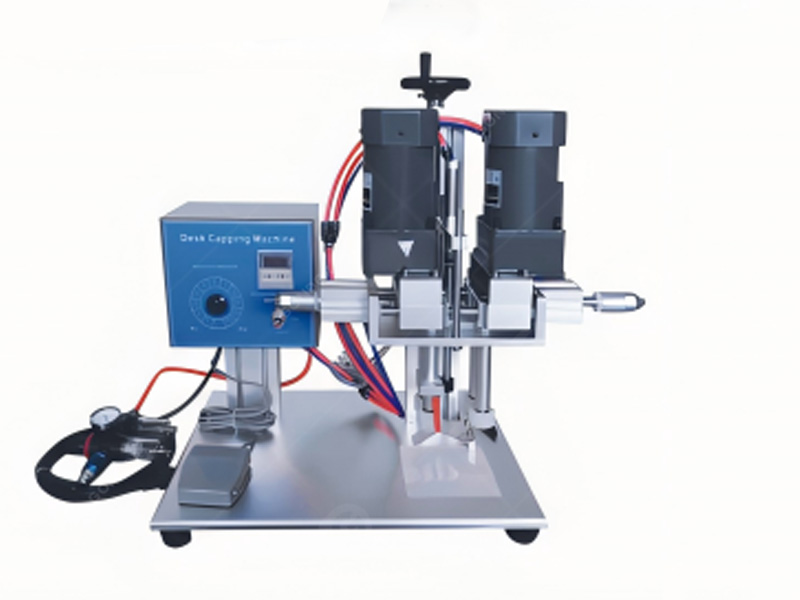

- Desktop Capping Machine: This compact, efficient capping machine is designed for sealing bottles of various sizes. With its user-friendly interface and adjustable settings, it provides precise and consistent cap sealing, which is ideal for small to medium-scale production lines.

- Automatic Electromagnetic Induction Aluminum Foil Sealing Machine: This machine utilizes electromagnetic induction to securely seal aluminum foil onto containers, ensuring leak-proof packaging. Equipped with automatic functionality, it enhances production speed and guarantees airtight seals for a variety of products.

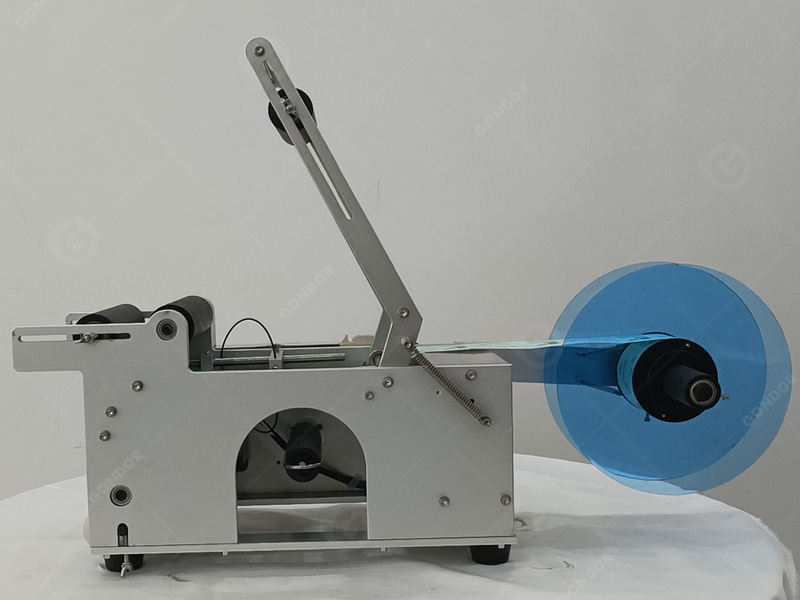

- Round Bottle Label Machine: Designed for efficiently applying labels to round bottles, this machine ensures precise and wrinkle-free labeling. With adjustable settings and automatic operation, it is suitable for a wide range of bottle sizes, which improves both production speed and presentation quality.

Food Security Belt Conveyor Metal Detector

The food security belt conveyor metal detector is designed to ensure the safety and quality of food products by detecting and removing metal contaminants during production. With its highly sensitive detection system and a user-friendly interface, it not only improves food safety standards but also enhances production efficiency. Furthermore, its belt conveyor design allows for seamless integration into existing production lines, which makes it an essential tool for maintaining food security in various processing environments.Flexibility and Scalability

These machines not only demonstrate high performance but also offer remarkable flexibility and scalability. For this reason, this adaptability allows clients to make adjustments and expansions according to their future production needs. Whether it involves increasing line capacity or introducing new products, our customized solutions can seamlessly accommodate any changes.

Professional Support and Services

Our dedicated team provides ongoing technical support, along with regular maintenance and training services, which ensures that your equipment remains in optimal working condition. This comprehensive support enables clients to enhance production efficiency, which can help them maintain a competitive edge in a challenging market. Through our complete commercial peanut butter making machine solution, Gondor machinery is committed to delivering quality products and services that empower our clients’ business success.

High-Efficiency Commercial Peanut Butter Making Machine Solutions in Gondor

To meet the specific needs of our client in nut chocolate spread production, we offered a high-efficiency, stable commercial peanut butter making machine solution. This production line not only enhances production efficiency but also ensures product quality, which makes it particularly suitable for producing various nut chocolate spreads. Below are the main features, advantages, and key equipment of the peanut butter production line:

Features and Advantages of the Peanut Butter Production Line

Efficiency

The optimized design not only achieves a remarkable production capacity of 50kg/h but also effectively meets large-scale production needs, which enables rapid responses to market demands.

Ease of Operation

Featuring high levels of automation, the peanut butter production line is designed for ease of use, minimizing manual intervention and reducing skill requirements for operators, which accelerates production timelines.

Scalability

As your business continues to expand, the production line can be easily scaled or upgraded to accommodate increasing production demands, which ensures long-term adaptability and sustained growth potential for your operations.

Safety

Equipped with advanced metal detectors and additional safety devices, the commercial peanut butter making machine guarantees hygiene and safety throughout the production process, which ultimately enhances consumer trust.

Stability

Each machine undergoes rigorous testing, which can ensure stable performance during continuous production. For this reason, it significantly reduces failure rates and enhances overall efficiency.

Versatility

The production line is highly versatile, and suitable for crafting various nut chocolate spreads. Its flexible configurations can accommodate different recipes and flavor requirements, which cater to diverse market preferences.

Qatar Peanut Butter Production Line: Future Collaboration Opportunities

As Gondor Machinery continues its partnership with the Qatari coffee chain, the potential for future collaborations is immense. Leveraging our innovative commercial peanut butter making machines, we aim to explore additional product lines, including organic and specialty spreads, which cater to evolving consumer preferences. What’s more, by integrating advanced technology and market insights, we can enhance product offerings and streamline production processes further. Meanwhile, our commitment to ongoing support and tailored solutions positions us as a key ally in the coffee chain’s growth, which can ensure they remain at the forefront of the competitive food market in Qatar.

Contact Gondor Machinery: Building a Bright Future Together

In summary, our collaboration with the Qatari coffee chain exemplifies our commitment to innovation and quality in food processing machinery. By delivering customized commercial peanut butter making machines, we empower our client to expand their product offerings and enhance market competitiveness. Furthermore, our comprehensive support ensures seamless production efficiency and product excellence. As we look to the future, we warmly invite potential partners to explore how our advanced food processing and packaging machinery can elevate their operations. Let’s connect and build a prosperous future together – contact Gondor machinery today to discuss your needs and discover tailored solutions for your business!