In recent years, the global chocolate market has been booming, especially in Asia and Africa, where demand continues to grow. As the demand for chocolate production increases, chocolate production equipment has gradually ushered in new technological innovations and development opportunities. Whether it is a small handmade chocolate workshop or a large commercial production plant, the commercial chocolate making machine and other equipment have become the key for manufacturers to improve production efficiency and ensure product quality.

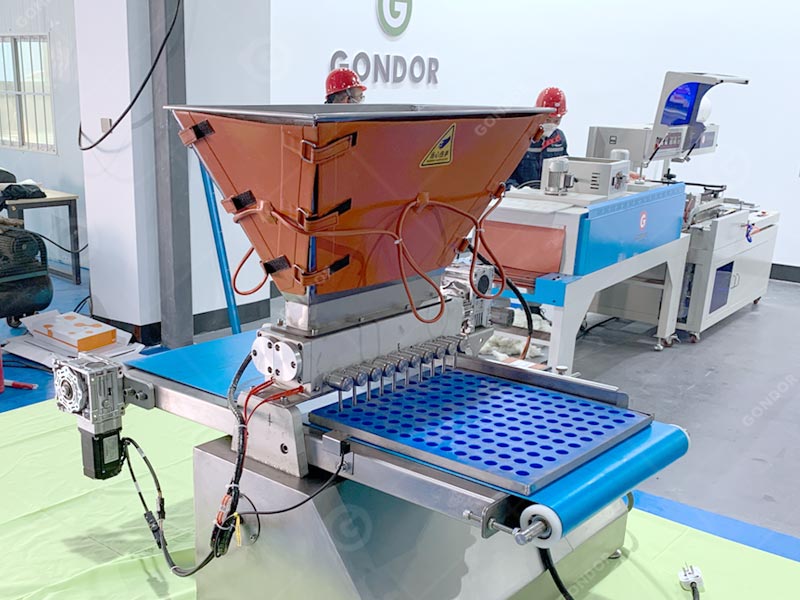

Chocolate Moulding Machine for Sale

With the continuous development of the chocolate market, consumers’ demand for chocolate products has shown a trend of diversification and personalization, which has prompted the continuous innovation of chocolate manufacturing equipment. chocolate moulding machine as a key equipment in modern chocolate production, its design and function are becoming more diversified and refined. The following are some of the main features and applications of this equipment in the current market:

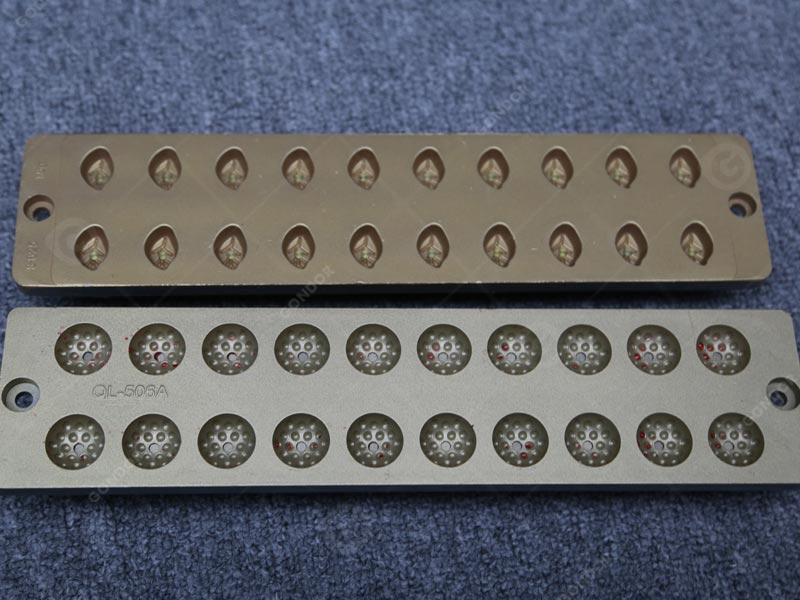

Support traditional blocks, complex shapes, and personalized customized molds to meet different market needs.

Accurately control filling speed, filling amount, and cooling temperature to ensure stable chocolate quality.

Quickly complete mass production, and flexibly adjust production speed to meet different batch requirements.

Design unique shapes and patterns according to consumer needs to enhance product differentiation and competitiveness.

Avoid bubbles and cracks to ensure a smooth and perfect appearance of chocolate.

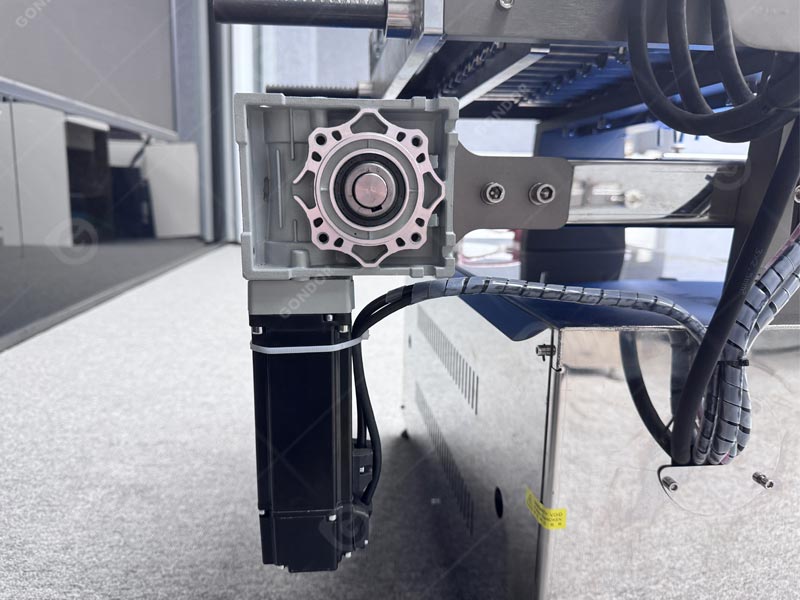

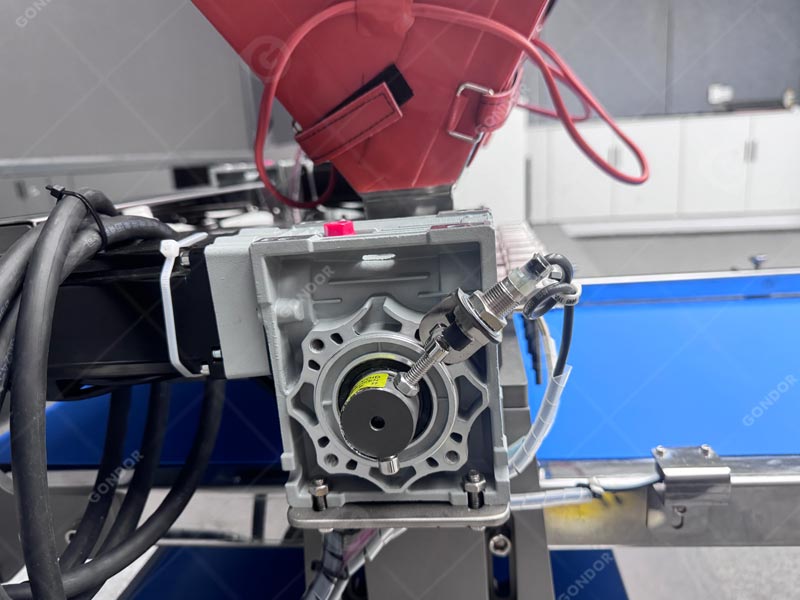

Integrated temperature adjustment, demoulding, and cooling functions to improve production efficiency and simplify processes.

Chocolate Processing Line: Improving Production Efficiency

The chocolate processing line is the core equipment of modern chocolate production, it covers multiple production links and has the following key features:

Commercial Chocolate-Making Machine: Adapting to the Commercial Needs of the Global Market

As the global market demand for high-quality chocolate increases, the demand for commercial chocolate making machines is also growing rapidly. Here are some key features of commercial chocolate making machines:

Supports large-scale production, improves production efficiency, and reduces unit costs.

Able to produce a variety of products such as cream chocolate, dark chocolate, white chocolate, etc. to meet different market needs.

High degree of automation, reduces labor costs and ensures the stability of the production process.

Easy operation, easy maintenance, and reduced equipment failures and downtime.

Quickly adjust production settings according to different consumer needs to enhance market competitiveness.

Industry Trends and Equipment Innovation: Intelligence and Environmental Protection

As environmental protection requirements increase, chocolate manufacturers are seeking more energy-saving and environmentally friendly production methods. Modern chocolate mold machines and processing lines are equipped with intelligent temperature control and energy efficiency optimization functions to reduce energy consumption while ensuring quality. Commercial chocolate manufacturing machines, by adopting environmentally friendly materials and processes, are driving the industry towards sustainable development.

Cooperate with Gondor to Seize the Chocolate Market Opportunity

With the rapid development of the chocolate industry, chocolate mold machines and other equipment have become the key to improving production efficiency and product quality. Combined with supporting equipment such as chocolate tempering machines and chocolate packaging machines, the production process will be further optimized and the overall capacity will be improved. Choosing the right equipment can bring more market opportunities to the company. Welcome to contact us to jointly promote the future development of the chocolate industry.