Making high-quality chocolate requires not only selected raw materials but also professional cacao processing equipment. A melange chocolate refiner can help you make chocolate with a smooth taste and rich flavor. In this article, we will introduce how to make delicious chocolate with chocolate equipment and ensure the high quality of the final product.

Step 1: Use of Melanger Chocolate Refiner

A melanger chocolate refiner is an important piece of equipment in the chocolate-making process. It is mainly used to refine cocoa beans, sugar, and other raw materials into fine chocolate liquid. Using a melanger can significantly improve the taste and texture of chocolate.

Usage Steps

After being processed by chocolate stone grinder, the chocolate liquid should be smooth and uniform in texture, laying the foundation for the next step of production.

Step 2: Application of Cocoa Processing Equipment

Although the melanger chocolate refiner can refine cocoa beans and sugar into liquid, cocoa processing equipment is indispensable to further optimize the taste and texture of chocolate. It can further remove the bitter taste in cocoa and improve the fluidity and smoothness of chocolate.

The Role of Cocoa Processing Equipment:

- Remove Impurities: Cocoa processing equipment removes residues in cocoa through further refining, making chocolate more delicate.

- Improve Taste: It helps to enhance the richness and smoothness of chocolate, making the final product more delicious.

Step 3: Fine Processing of Ball Mill Chocolate Machine

Although the chocolate grinder machine and cocoa processing machine have already refined the chocolate liquid initially, the ball mill chocolate machine is the last key equipment to ensure that the chocolate is completely smooth. The ball mill further refines the fine particles in the chocolate through the high-speed impact of the grinding balls, helping you to make smoother chocolate.

Operation Steps of the Ball Mill Chocolate Machine:

Add the chocolate liquid that has been refined by melanger and processed by cocoa to the ball mill.

The chocolate ball mill machine uses grinding balls (usually steel balls or ceramic balls) to continuously hit the chocolate in a closed environment to help further remove particles and improve its fineness.

This process usually takes several hours, depending on the desired fineness of the chocolate. The appropriate grinding time can bring a smoother chocolate texture.

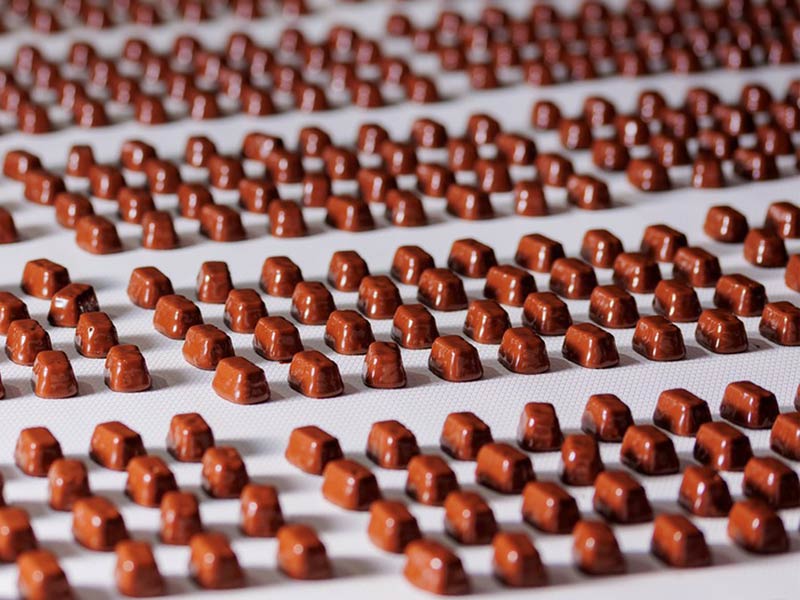

Step 4: Tempering and Molding

After the chocolate has been ground, the next step is tempering and molding. Tempering is a key step to ensure that the chocolate has gloss and hardness when it is molded.

Equipment Integration Improves Chocolate Quality

By using these cacao processing equipment together, you can make chocolate with a delicate taste and excellent quality. Combined with chocolate wrapping machines, chocolate enrobing machines, and other equipment, you can further improve production efficiency and product quality. Our company provides a full set of chocolate production line equipment to help you keep improving in every production link and create higher-quality chocolate.