Against the backdrop of the continuous integration of the global economy, the bond of international trade closely connects enterprises from different countries. In July 2024, we welcomed a new customer – a customer from Paju City, Gyeonggi Province, South Korea. The customer’s procurement goal this time is clear. They urgently need Gondor DIPM100 dry ice pelletizer, and also need matching CO2 storage tanks and dry ice insulation boxes.

Gondor DIPM100 Dry Ice Pelletizer Machine

Rear View of DIPM100 Dry Ice Pelletizer

Gondor Dry Ice Pellet Maker Parameters and Machine Features

Parameter:

- Power: 3kw

- Voltage: 220V/380V

- Weight: 175kg

- Depositing Nozzles: 10

- Output: 50kg/h

Main Features:

- Sturdy and Durable Structure

- Low Wear

- Light Weight

- Efficient Production

Background Introduction of Dry Ice Pelletizer Project

The client has extensive experience in the field of mechanical equipment, and their 45-year industry history has witnessed their professionalism and persistence. Because their cleaning vehicle project has strict requirements on equipment and the output needs to reach 100kg/h, they found our company online through their Chinese friends.

Customers Come to China to Visit Gondor Factory

In late August 2024, the customer came to China to visit the factory. The customer’s visit schedule was compact and efficient. Finally, after communication and negotiation, the customer had a deeper understanding and trust in our products and services. They decisively placed an order and chose our 100-type dry ice pelletizer, CO2 storage tank, and dry ice insulation box.

Gondor Factory Is in Full Production

At present, the factory is in full swing. The production cycle is about 20 days, and it is expected to be completed and shipped in mid-September. We will strictly control every production link to ensure that the product quality meets customer requirements. At the same time, we will also make preparations for shipment in advance to ensure that the goods can be delivered to customers safely and promptly.

Why Customers Choose Gondor?

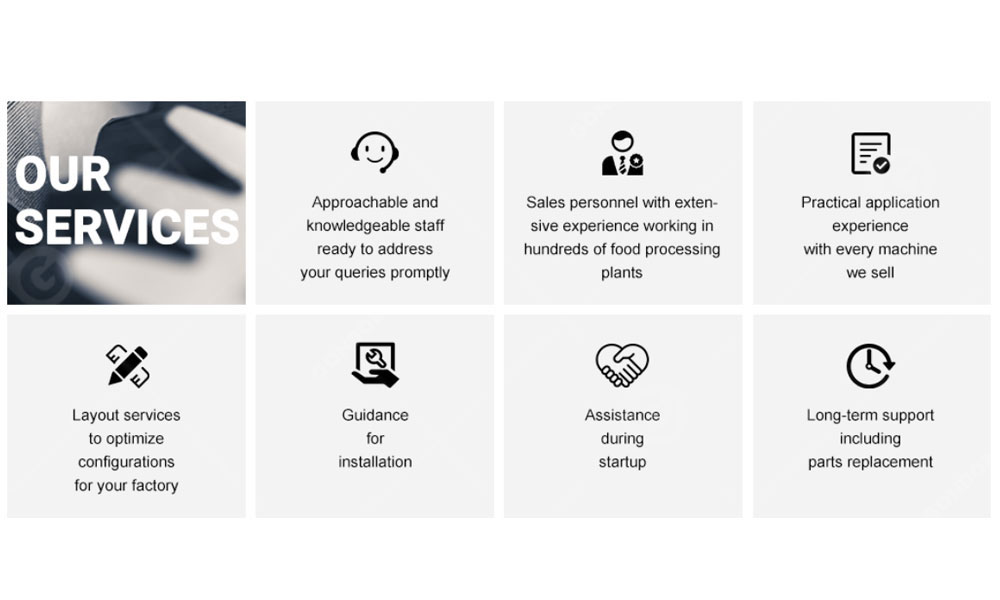

We have a professional R&D team, and we are constantly committed to technological innovation and product upgrades to meet the different needs of the market. At the same time, the scale of our factory is sufficient to support large-scale production tasks and ensure the timely delivery of high-quality products. Moreover, we also have perfect after-sales guarantees to solve the worries of customers, so that they can use them without any worries.

Gondor Group – Top Food Processing and Packaging Machinery Supplier

This visit and cooperation with Korean customers is another successful breakthrough for our company in the international market. It not only proves the competitiveness of our products in the international market, but also provides a broader space for our future development. We will continue to provide equipment and solutions for food processing and packaging machinery to more customers. Click below to contact us to get exclusive machinery customization solutions and start projects with higher returns on investment!