Chocolate making is not only an art but also a technical job. From the selection of raw materials to the carving of the finished product, every step is inseparable from efficient and precise equipment. In this article, we will focus on key equipment such as the cocoa butter extraction machine to take you into the chocolate-making process and help you understand how to make high-quality chocolate with advanced equipment.

Selection and Processing of Cocoa Beans

In any chocolate-making process, the selection of high-quality cocoa beans is the key to success. After the carefully selected cocoa beans are roasted and fermented, they enter the initial processing stage. At this time, chocolate processing machinery comes in handy. The equipment breaks the cocoa beans through a series of processing procedures, separating the cocoa kernels and shells, and preparing for the subsequent production steps.

Cocoa Butter Extraction Machine: Separation and Purification

After the initial processing of cocoa beans, the next step is to extract cocoa butter and cocoa powder, which are the core ingredients of chocolate. The cocoa press machine plays a key role in this process. Through physical pressing, it separates the cocoa butter from the cocoa powder in the cocoa beans and extracts high-quality cocoa butter, which determines the taste and gloss of the chocolate.

Application of Cocoa Butter:

- Cocoa butter is indispensable in chocolate production, which gives chocolate a silky taste and gloss.

- In addition to chocolate, it is also widely used in the cosmetics and pharmaceutical industries as a moisturizing ingredient.

Mixing and Blending of Chocolate

When the raw materials such as cocoa powder, cocoa butter, sugar, etc. are ready, the next step is mixing and blending. At this stage, chocolate processing machinery plays an important role, including the following aspects:

Shaping and Cooling: The Charm of Chocolate

When the chocolate paste is ready, the next step is the shaping and cooling process. The chocolate is poured into the mold and cooled to form the final shape. In addition to traditional molds, the automatic shaping and cooling system in chocolate processing machines can provide more precise and efficient production, ensuring that each piece of chocolate is smooth and delicate with a rich taste.

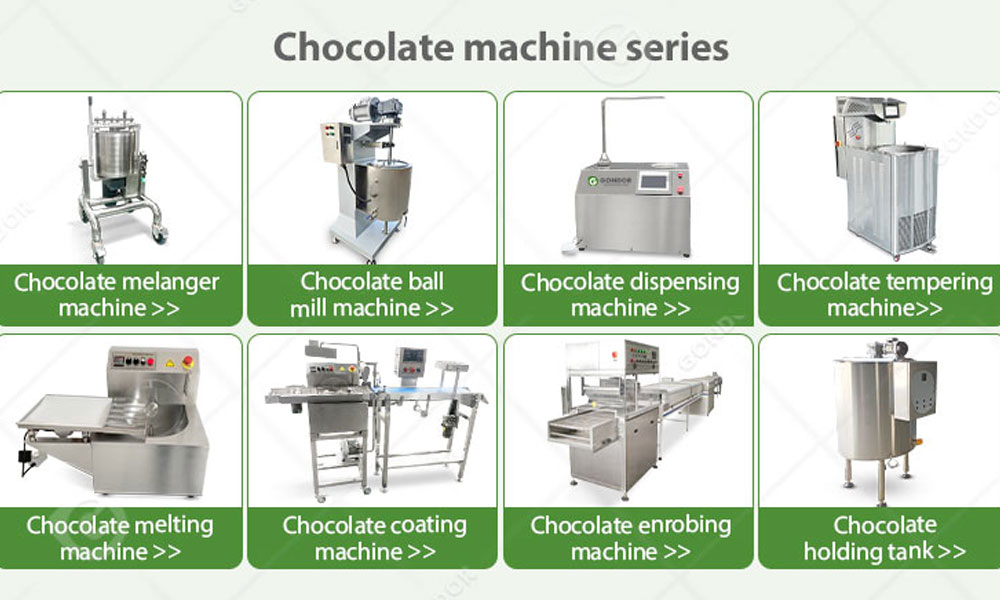

Other Related Equipment: Improve Production Efficiency

In addition to the core equipment mentioned above, the chocolate production process also involves a series of other auxiliary equipment, such as:

- Chocolate Grinder Machine: Grinds raw materials such as cocoa powder, cocoa butter, and sugar into fine chocolate paste to improve the taste and make the chocolate smoother.

- Chocolate Tempering Wheel: Evenly coats chocolate on the surface of candies or biscuits to ensure that each product has a perfect chocolate shell.

Efficient Equipment Helps the Future of the Chocolate Industry

By using advanced equipment such as the cocoa butter extraction machine, chocolate production is not only more efficient but the quality of the finished product is significantly improved. As the global demand for chocolate grows, modern equipment will play a key role in the industry.

If you are looking for professional chocolate production equipment, welcome to learn about our other chocolate equipment to help your production line run more efficiently and stably. Let us work together to create a better future for the chocolate industry!