Efficient Coating for Quality Food Production

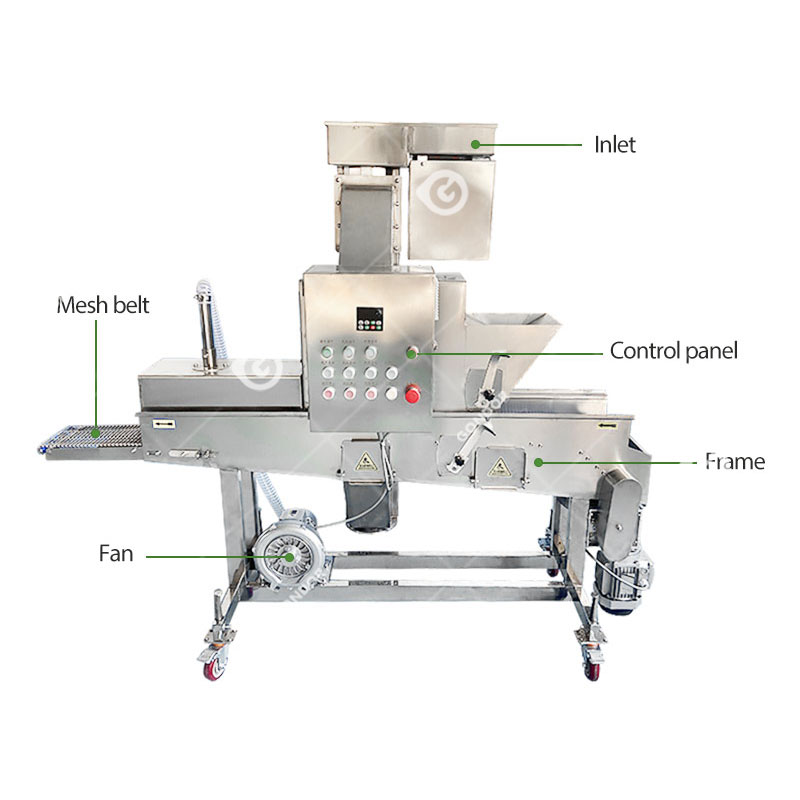

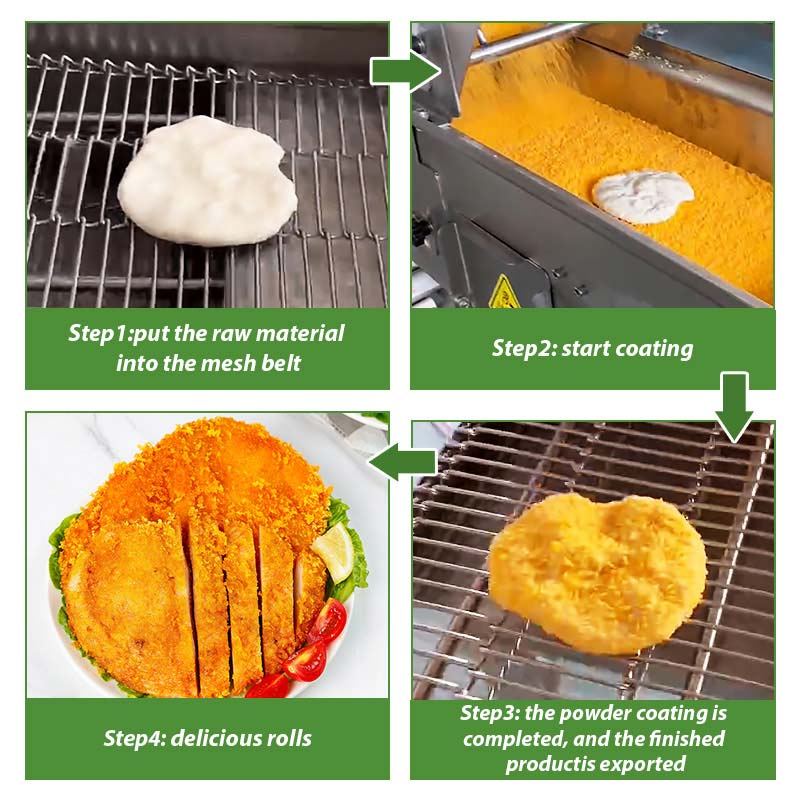

The Gondor automatic chicken breading machine is a purpose-built device engineered to apply a consistent and uniform layer of bran or breadcrumb coating onto various food products. Its robust construction typically includes a receiving feed port, a synchronized conveyor system, a high-efficiency bran spreading mechanism, and a regulated discharge outlet. In operation, food items are introduced at the feed point and carried steadily forward by the conveyor. The innovative design ensures that crumbs are continuously supplied both from the overhead hopper and strategically placed along the mesh belt, enveloping the product from multiple angles for complete, 360-degree coverage.

| Model | GD-200 | GD-400 | GD-600 |

| Belt Width | 200mm | 400mm | 600mm |

| Power | 0.86kw | 3.7kw | 3.7kw |

| Size | 1720*650*1400mm | 2638*1050*2280mm | 2638*1050*2280mm |

| Weight | 230kg | 450kg | 620kg |

Industries Related to Using Gondor Automatic Breading Machine

Considerable Benefits of Gondor Chicken Breading Machine

Improve Product Quality

Ensure that the bread crumbs are evenly attached, so that the finished product has a consistent appearance and better taste, thereby improving the market competitiveness of the product.

Increase Product Diversity

The coating thickness and formula can be adjusted according to different needs, and products of various flavors and styles can be produced to meet a wider range of market needs.

Energy Saving and Environmental Protection

The efficient operation mode saves energy relatively, meets the requirements of sustainable development, and reduces long-term operating costs.

Improve Production Efficiency

It can quickly and evenly coat food with bread crumbs, greatly shorten processing time, and increase output per unit time.

Save Raw Materials

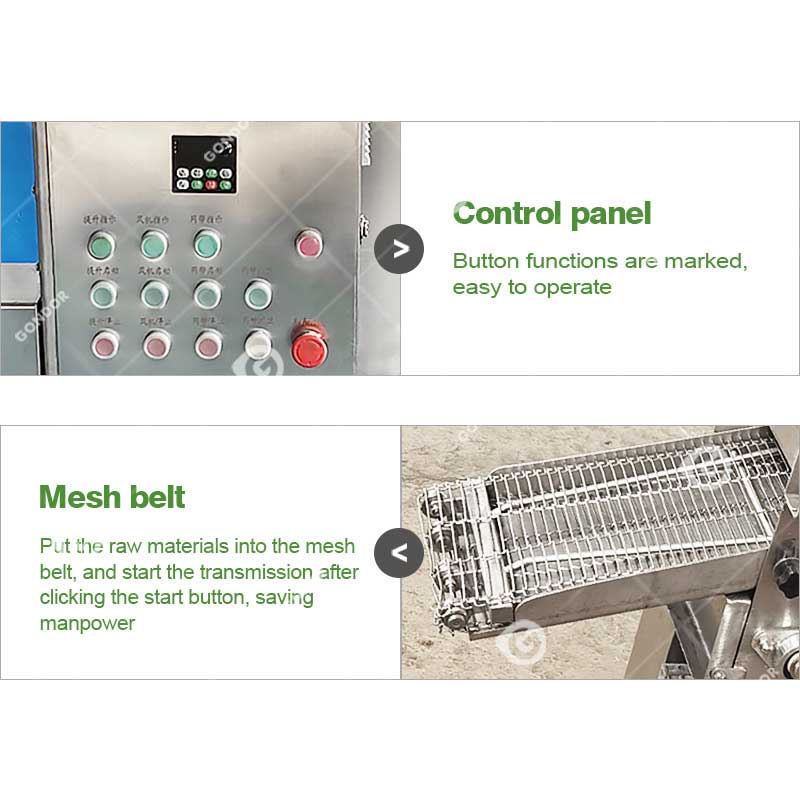

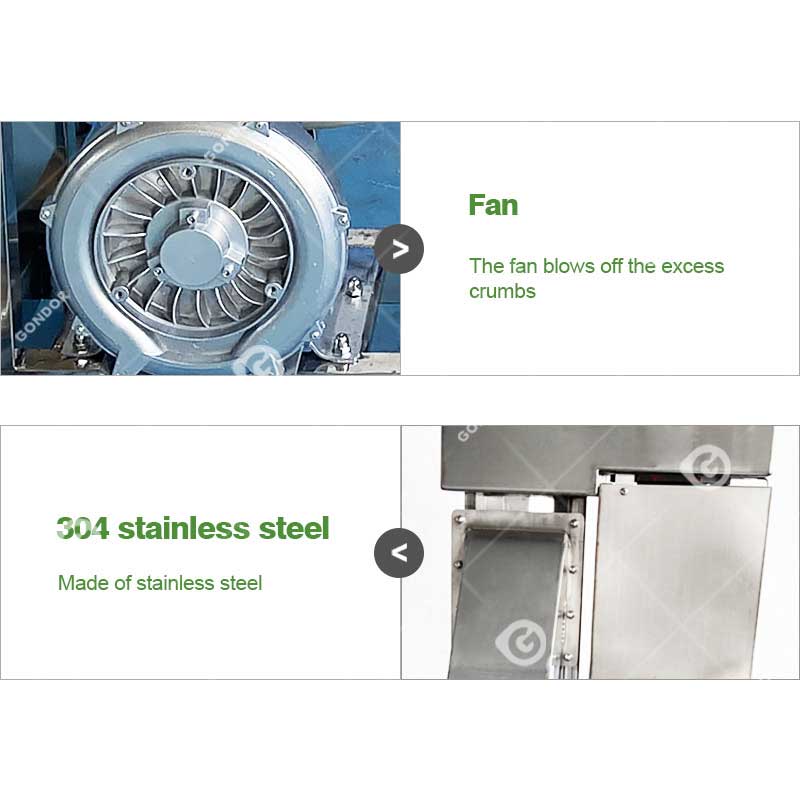

Adjust the amount of bread crumbs, and then blow away the excess crumbs through a strong wind system.

Safe and Durable

Made of stainless steel, reasonable structure, long service life. Good safety protection performance and simple operation.

Building a Complete Coating and Frying Production Line

The breadcrumb coating machine is a core component in food processing lines, with its maximum efficiency realized through seamless integration with upstream and downstream equipment. Through scientific layout, a highly automated continuous production system can be established.

Pre-processing Equipment Integration:

- Automatic Patty Forming Machine: Processes raw meat into standardized shapes (e.g., round patties) and feeds them directly onto the coating machine via conveyor belts, ensuring uniform dimensions for consistent coating.

- Batter Coater: Before breading, evenly coats food surfaces with a liquid batter (flour mixture or egg wash) as an adhesive to ensure secure breading adhesion.

Post-Processing Equipment Integration:

- Continuous Frying Machine: Coated food enters the frying line directly, undergoing shaping and cooking at preset temperatures and times to form a golden, crispy crust.

- Hot Air Baking Line (Healthy Alternative): For low-fat products, connect to baking equipment that uses hot air instead of oil for healthier cooking.

- IQF Tunnel Freezer: When producing frozen prepared meals, fried/baked products immediately enter the quick-freezing tunnel to lock in juices and flavor.

Gondor Automatic Chicken Breading Machine – A Must-Have for Delicious Upgrades

If you are still looking for an automatic chicken breading machine, Gondor Machinery is your best choice to improve product quality! Our automatic breading machine is easy to operate and has a uniform coating, which can add an attractive appeal to your food. Precise control saves raw materials, and efficient operation increases production. Moreover, we provide high-quality after-sales service, so you don’t have to worry about it. Choosing Gondor means choosing efficiency and quality. Come and buy it and start a new journey of deliciousness!