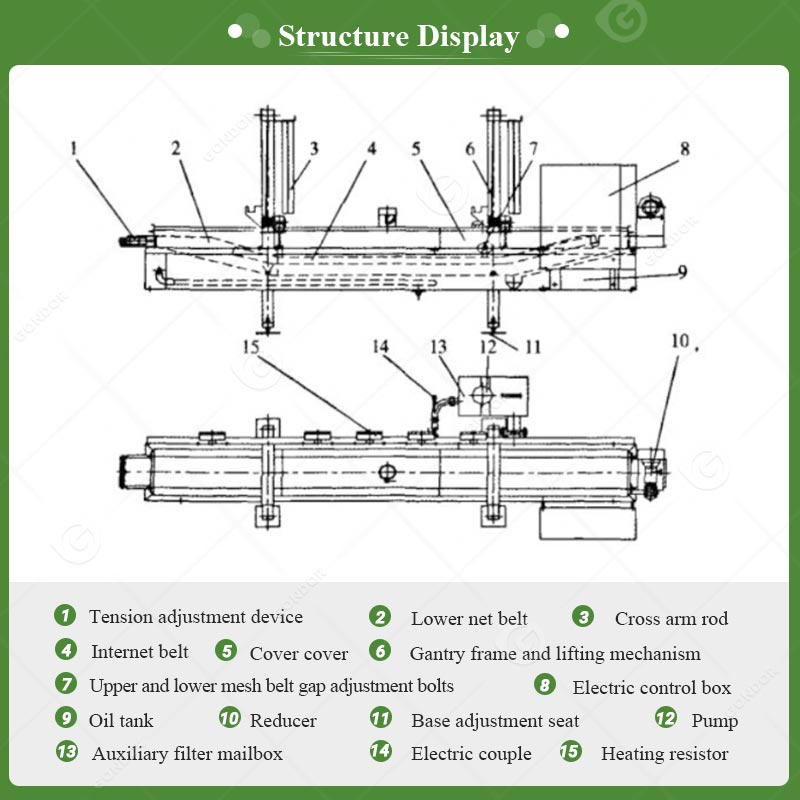

Automatic continuous fryer frying machine is made of SUS304 stainless steel, which is assembled after one-time processing. It consists of 7 major parts: oil fume collection device, mesh belt conveyor system, electric heating system, reinforced insulation oil tank, double residue filtering system, lifting system, and electrical control system. Moreover, the whole machine runs smoothly and noiselessly, and the conveying system and oil tank can be separated for easy cleaning. In addition, the electrical control part monitors the operating status of the whole machine and is equipped with an alarm device, making production safer. It is suitable for various food processing companies.

Gondor Continuous Frying Machine Factory Photo

| Model | Width of belt | Length | Heating method | Temperature |

| GD-CFM400 | 400mm | 2m-8.5m (Customizable) | Electricity / Gas | Within 300℃ |

| GD-CFM600 | 600mm | |||

| GD-CFM800 | 800mm | |||

| GD-CFM1000 | 1000mm | |||

| GD-CFM1200 | 1200mm |

Gondor Automatic Continuous Fryer Main Application Industry

Food Processing Industry

Production of snack foods, fried snacks, breakfast food processing, etc.

Meat Processing Industry

Production of meat products such as fried chicken steaks and fried pork chops.

Aquatic Product Processing Industry

Processing of aquatic products such as fried fish nuggets, fried shrimps, and fried squid rings.

Fast Food Chain Industry

Provide a large amount of fried foods for major fast food chain brands.

Central Kitchen

Centrally supply fried foods for multiple catering venues.

Baking Industry

Make some special baked products that require frying processes.

Convenient Food Industry

Produce all kinds of convenient and fast fried foods.

Frozen Food Industry

Fry first and then freeze and package to extend the shelf life of food and maintain taste.

Main Features of Gondor Continuous Frying Machine

Frequency Conversion Speed Regulation

The mesh belt is made of stainless steel, and adopts frequency conversion stepless speed regulation, and the frying time is adjustable.

Automatic Lifting

It is equipped with an automatic lifting system, and the upper cover and mesh belt can be raised and lowered, which is convenient for manual cleaning.

Automatic Slag Discharge

It is equipped with automatic residue discharge system, the residue can be discharged at any time without affecting the frying effect.

Dynamic Circulation

It is equipped with a dynamic circulation system to filter out the oil residue during the production process, reduce the acid value of the oil, and extend the service life of edible oil.

Double-layer Transmission

It adopts upper and lower double-layer mesh belt transmission, and the product is sandwiched between the double-layer mesh belt to prevent the product from floating.

Gondor Fryer Detail

Gondor Frying Machine Display

Gondor Group – Continuous Fryer for Sale

If you are looking for a fryer, you might want to check out the Gondor automatic continuous food frying machine. Our machine has a double-layer mesh belt transmission, the product is stable and does not float, the frying effect is excellent, and it can help you seize the market opportunity.