Automatic premade pouch bag pack filling machine is an efficient and precise automated packaging solution that caters to a wide range of food and non-food industries. Not only is it easy to operate, but it is also equipped with a 7-inch multi-language Siemens touch screen, allowing most parameters to be set with ease. Additionally, the machine utilizes a high-precision multi-head scale, which ensures excellent packaging accuracy and stability. Furthermore, the equipment supports fully automated feeding, dosing, bag making, and sealing, enabling a streamlined process. The packaging bags can be configured to stand upright or include euro holes, hooks, and production dates, enhancing versatility. As for packaging film, it is compatible with laminated bags, PE bags, aluminum bags, and paper bags and can be fashioned into a variety of bag types, such as stand-up bags, zipper bags, or flat bags. Particularly suitable for high-precision and fragile products—such as puffed foods, potato chips, jellies, nuts, frozen foods, and coffee beans—this bag pack machine stands out as an ideal packaging solution across various industries.

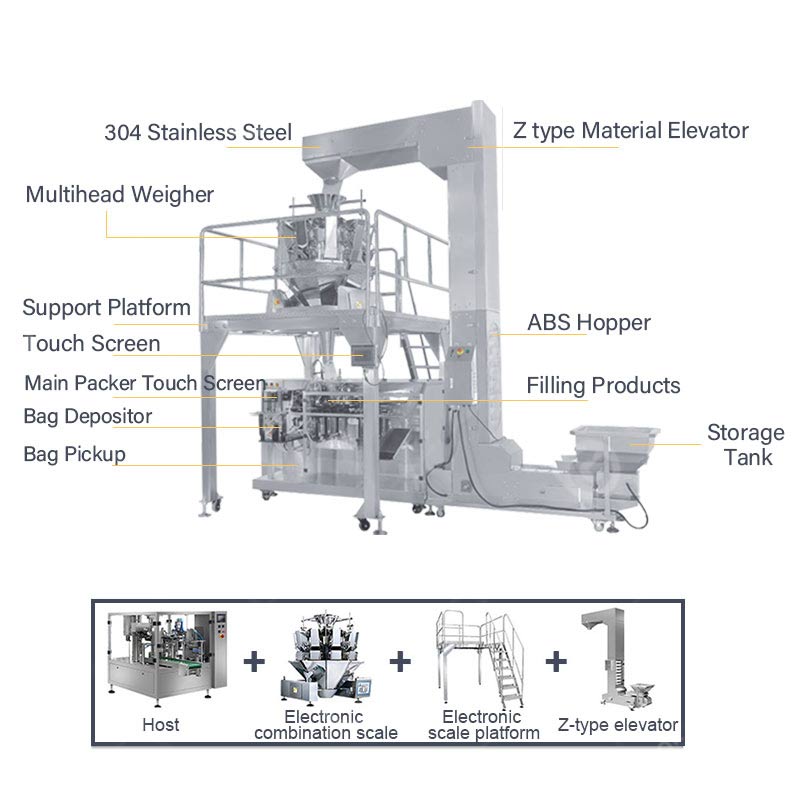

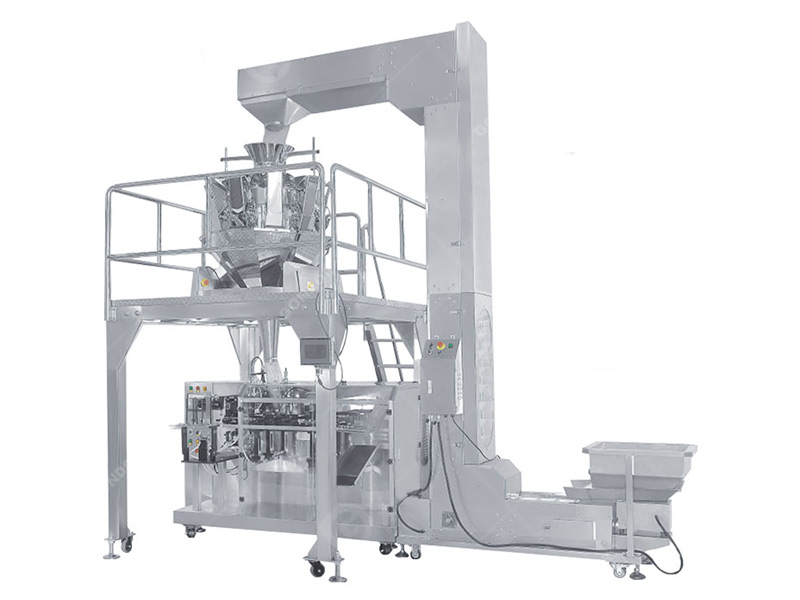

Gondor D-260 Host with Electronic Scale

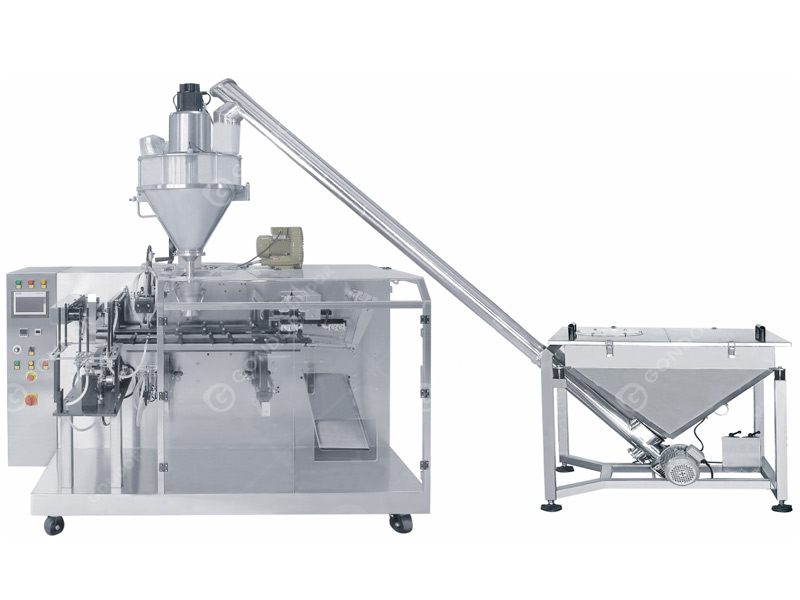

Gondor D-260 Host with Screw

|

Model

|

GD-DM160

|

GD-DM210

|

GD-DM260

|

|

Bag size

|

L:100-250mm

W: 60-160mm |

L:100-320mm

W: 120-210mm |

L:110-350mm

W: 140-210mm |

|

Measuring Range

|

10-1000g

|

50-1250g

|

100-1500g

|

|

Packing Speed

|

25-45bags/min

|

||

|

Power Supply

|

380V 3P 50/60hz

|

||

|

Gas Consumption

|

≤0.3m³/min

|

≤0.4m³/min

|

≤0.5m³/min

|

|

Bag Type

|

Stand bag, zipper bag, flat bag, eg. 3 side seal, 4 side seal, bag with punched hole handle, pillow bag etc.

|

||

|

Machine Size

|

1700*1050*1100mm

|

21501200*1200mm

|

2450*1350*1300mm

|

Wide Application Market Scope of Premade Pouch Filling Machine

The following industries can use bag-feeding packaging machines to improve packaging efficiency, ensure packaging accuracy, and adapt to a variety of packaging bag types to meet the packaging needs of different products.

Unique Performance Characteristics of Gondor Automatic Pouch Filling Machine

Gondor Bag Pack Machine – Efficient and Intelligent Packaging Solutions

Choose Gondor automatic premade pouch bag pack filling machine to bring more efficient and accurate packaging experience to your production! This machine adopts advanced three-servo control system and electric eye color tracking to achieve efficient and fast packaging. Moreover, the equipment is fully automated, including bag placing, bag clamping, coding, bag opening, material feeding and bag sealing processes, without manual intervention, greatly improving production efficiency. In addition, the machine accurately feeds materials with an accuracy error as small as 0.5g, ensuring that each product is perfectly sealed. Click below to send an inquiry to learn more about how Gondor machines can help your business development!