Automatic Sausage Production Line From Gondor Machinery

The automatic sausage production line from Gondor machinery is a comprehensive system that is designed to produce sausages efficiently and consistently. And our sausage production lines will streamline the entire process from grinding the meat to packaging the final product. However, our production lines can ensure high-quality sausages for consumers. Moreover, the sausage production lines from Gondor play a crucial role in the food processing industry.

With the development of technological innovation and the changing demands of customers, the sausage production lines in Gondor will continue to evolve, which will offer even more benefits to the industry. Just leave your demand to Gondor and we will be your optimal selection to expand your business!

Automatic Sausage Production Line for Sale in Gondor Machinery

Packing and Delivery for Automatic Sausage Production Line

Application Scenarios for Automatic Sausage Production Line

Sausage production lines are essential for large-scale manufacturing. They enable companies to produce vast quantities of sausages to meet consumer demand. Gondor machinery provides different production lines to produce sausages. The mass production of these automatic sausage processing lines can meet the needs of many scenarios where sausages should be produced in large quantities. Here are some examples of where the production lines from Gondor have been purchased and installed:

- Specializes in large-scale industrial production of sausages.Food Processing Industry

- Combines deep processing of meat to produce various specialty sausage products.Meat Processing Enterprises

- Provides customized sausage products for chain restaurants for dish preparation.Catering Chain Industry

- Meets the demand for high-quality sausages, used in banquets and other occasions.Hotel Industry

- Produces various ready-to-eat sausage foods.Cooked Food Processing

- Supplies packaged sausages to meet the daily purchases of consumers.Supermarket & Stores:

- Produces sausages that meet export standards for international market sales.Food Export Industry

- OEM production of sausages for other brands.Food OEM Industry

Why Choose Gondor Automatic Sausage Production Line?

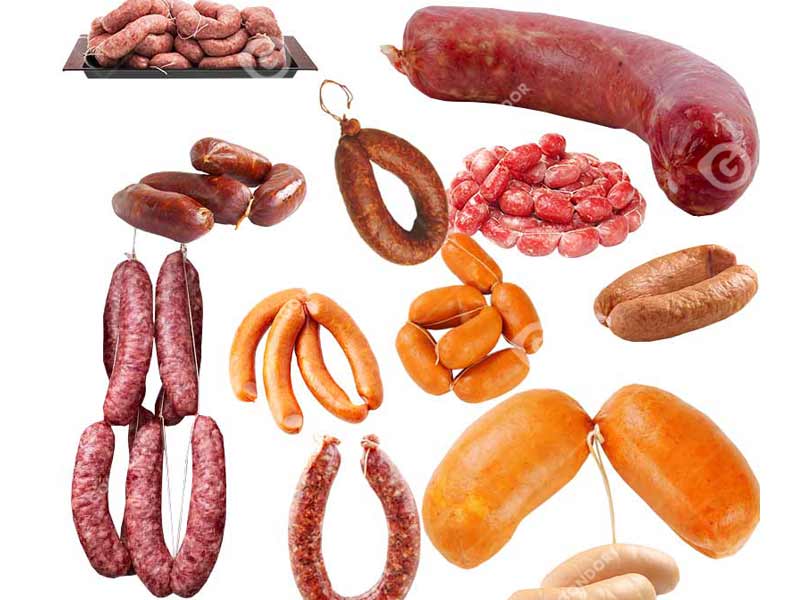

The fully automatic sausage production line is highly automated, significantly improving production efficiency and saving labor costs. The automatic system realizes intelligent control from raw material processing to sausage forming and packing. In addition, this sausage processing line also has flexibility and can be customized according to your different needs to meet the production of various specifications and types of sausages. Here are some advantages of sausage production lines in Gondor machinery:

Highly Automated

Implement automated processes from raw material processing to finished product packaging, reduce manual intervention, and improve production efficiency.

Accurate Control

Precisely controls parameters such as temperature, ingredient ratio, and processing time to ensure stable sausage quality.

Multi-functionality

It can produce various flavors, types, and specifications of sausages to meet different market demands.

Efficient Production

The fully automatic sausage production lines in Gondor can complete the production of sausages in a shorter time, which will shorten the production cycle.

Strong Stability

The automatic sausage production line can operate stably and reliably in the whole process, which will greatly reduce the faults and downtime.

Health and Safety

In Gondor machinery, we adopt the quality SUS304 stainless steel to produce the production lines, which can guarantee the hygiene and product safety.

Intelligent Operation

Gondor automatic sausage production lines are equipped with an intelligent operating system for convenient operation and management.

Energy Conservation and efficiency

We pay much more attention to the rational utilization of energy in the production process and reduce energy consumption.

Lower Noise

In Gondor, we provide the sausage production lines which have features of a large capacity enema bowl with low load, and produce lower noise.

Gondor Sausage Production Lines: Detailed Advantages and Specifications

In Gondor machinery, there are various sausage production lines to satisfy the different demands of our customers. For instance, according to the technology type of the production lines, Gondor offers the pneumatic sausage production lines and the hydraulic sausage production lines. Likewise, depending on the type of sausage being made, the production line can be categorized into machinery for producing meat paste sausages and machinery for producing chunked meat sausages. Below, I will list the product details and advantages for your reference.

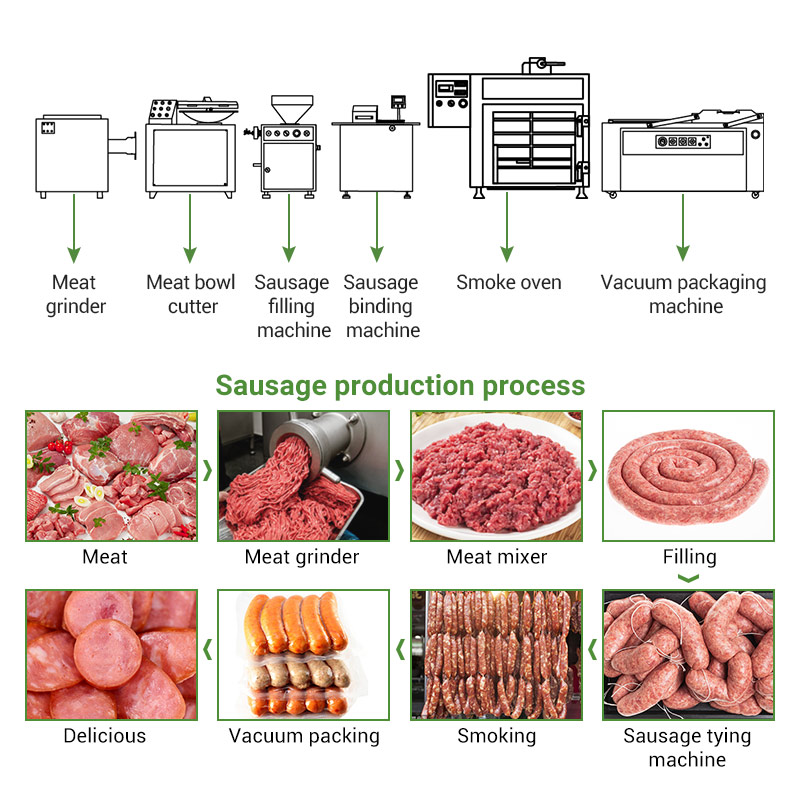

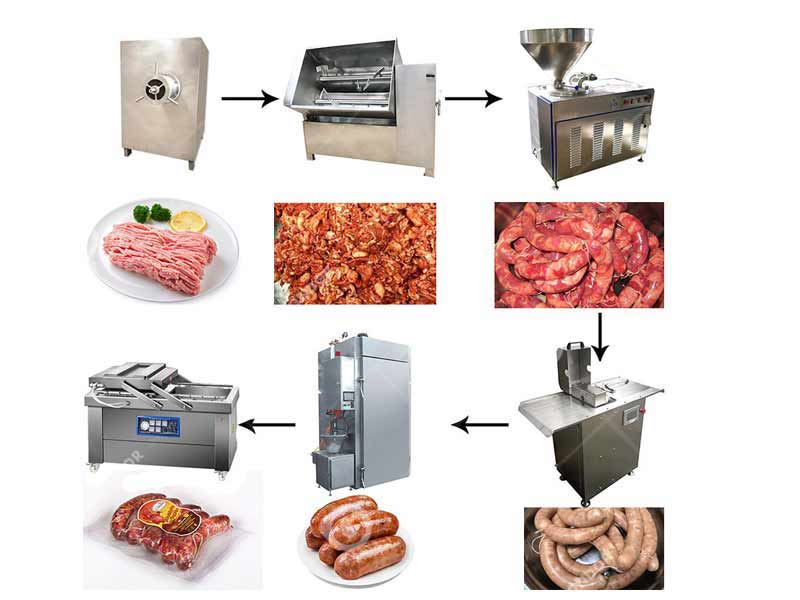

Meat Grinder

The meat grinder of the Gondor sausage production line utilizes a screw-feeding mode, which shows strength in easy operation.

Meat Chopper Machine

The meat chopper machine of our production line is equipped with an automatic discharge device, which can automatically discharge the material after the work is completed. Therefore, it can save labor for our clients.

Sausage Filling Machine

The sausage filling machine can automatically fill sausage casings with the sausage mixture, which can significantly improve the production efficiency. In the meantime, it can ensure uniform filling and an appealing appearance of the sausages.

Sausage Binding Machine

During the sausage packing process, the sausage binding machine can maximize the effectiveness of sausage production line. For instance, it can increase the packaging efficiency, ensure the packaging quality, reduce the costs, and improve the hygiene standards.

Sausage Smoking Chamber

The sausage smoking chamber features a highly automated design, which can make it easy to operate and is highly efficient in production. Besides, it can effectively reduce the labor costs and have a wide range of applications.

Stuffing Mixer

The stuffing mixer in the sausage production line can thoroughly and evenly combine minced meat and seasonings, and this can ensure the consistency in the texture and quality of the sausages. What’s more, our production line offers adjustable mixing speeds and parameters to accommodate various recipes and production requirements.

Sausage Meat Grinder

The sausage meat grinder can mince meat into fine particles rapidly, which will save time and labor costs compared with the manual grinding. At the same time, it also improves the uniformity and mixing of the ingredients, and guarantees the consistent product quality.

Sausage Chopper Machine

The sausage chopper machine of this production line can quickly chop, mix, and blend ingredients, and the production efficiency will be significantly improved. In other words, compared to manual operation, this can complete large-scale ingredient processing tasks in a much shorter time.

Smoking Chamber

The sausage production lines in Gondor are equipped with a smoking chamber, which can provide the sausages with a smoked flavor, as well as enhance their taste and variety. Meanwhile, it prolongs the shelf life of the sausages and enhances their market competitiveness, thereby increasing the added value of the product.

Key Factors Affecting the Automatic Sausage Production Line Price

Are you looking to buy an automatic sausage production line? Do you know what factors to consider that will affect the price of purchasing the production lines? When businesses are looking to invest in the sausage production line, it is fairly important to consider what affects the automatic sausage production line price is fairly different and investors should consider various factors comprehensively, including their budget and production demands, before purchasing the production line for their businesses. Moreover, this can help them make informed decisions and help them improve their return on investment. Here are the primary elements that affect the cost of an automatic sausage production lines:

- Automatic sausage production lines with higher output require advanced machinery and higher automation, leading to higher costs. Businesses should balance capacity needs and budgets to find a cost-effective solution.Production Capacity

- Unlike the semi-automatic production lines requiring more manual labor and less efficiency, fully automated sausage production lines reduce human intervention but are more expensive due to advanced technology.Level of Automation

- The materials (such as stainless steel and other durable materials) used in sausage production lines affect prices. High-quality materials increase initial costs but offer better longevity and reduce long-term maintenance.Quality of Materials

- It is obvious that customizable solutions with additional design and manufacturing costs will be priced higher. However, it will generate greater profits. In Gondor, we customize the machine to handle unique recipes, sizes, or techniques.Customized Solutions

- The price of purchasing a sausage production line is closely related to its shipping and installation, and at the same time, these factors can significantly impact the total investment cost. Businesses should choose the most cost-effective option.Transport & Installation

- It is a fairly important factor affecting the production line prices. And it is very reassuring to purchase food processing machinery with extended warranties and guarantees. Though it will increase the initial price, our clients will enjoy the protection and assurance with the passage of time.Warranty & Guarantees

- When businesses purchase sausage production lines from Gondor machinery, they also can benefit from the comprehensive after-sales services and supports from us. This will be very convenient and effortless.Sales Service & Support

| Machine | Model | Size | Power |

| Meat Grinder | GY-100 | 850*500*860 | 5.5kw |

| Meat Bowl Cutter | GY-100 | 1200*450*850 | 1.5kw |

| Sausage Filling Machine | GY-30 | 1050*670*1680 | 1.5kw |

| Sausage Tying Machine | Fully automatic single-waybinding machine | 1100*500*900 | 2kw |

| Smoke Oven | GY-100 | 1200*1700*2140 | 17.2kw |

| Vacuum Packing Machine | DZ-600 | 1300*700*600 | 2.25kw |

Buy Fully Automatic Sausage Production Line from Gondor Group

Cooperate With Gondor to Purchase Production Lines

When planning to invest in the food processing industry, it is a strategic decision to choose from many automatic sausage production lines manufacturers. And after investigation, you will find it is wise to select Gondor machinery, a leading manufacturer and supplier in the industry. At the same time, choosing efficient, high-quality, and reliable production solutions will help you achieve greater success and revenue in sausage production. Feel free to contact and cooperate with Gondor group here!