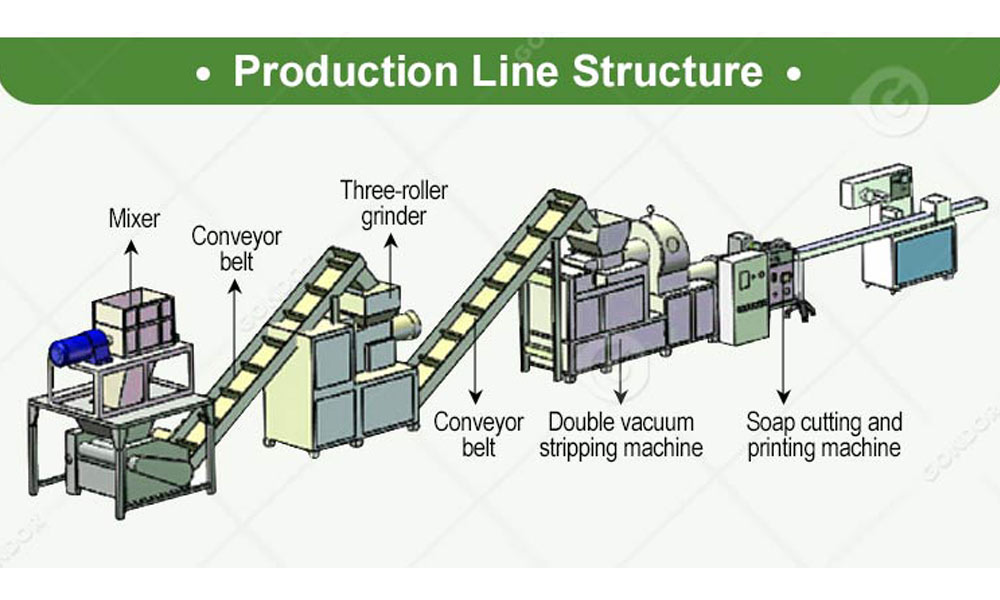

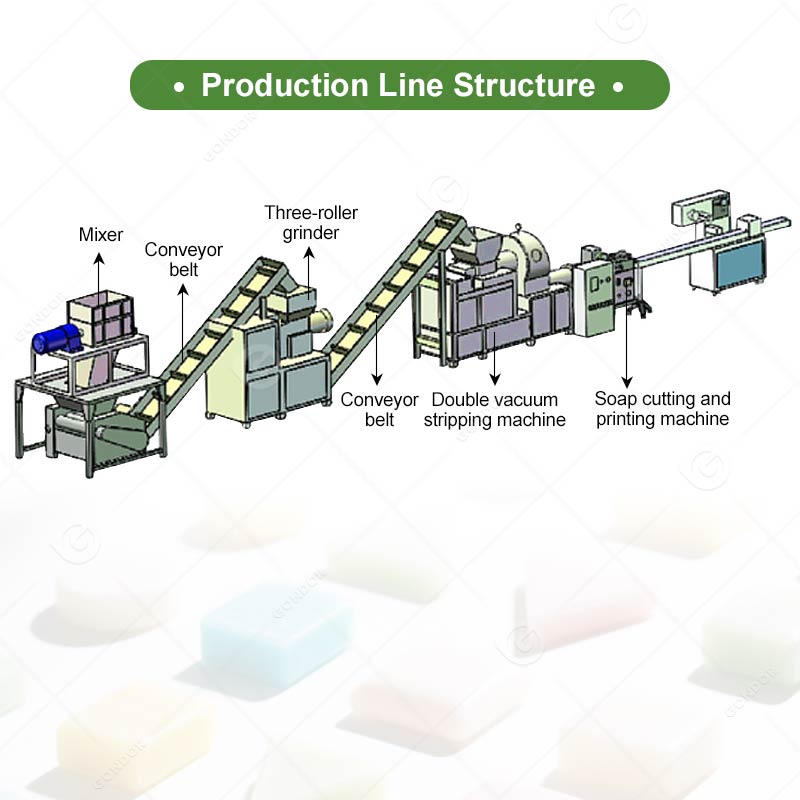

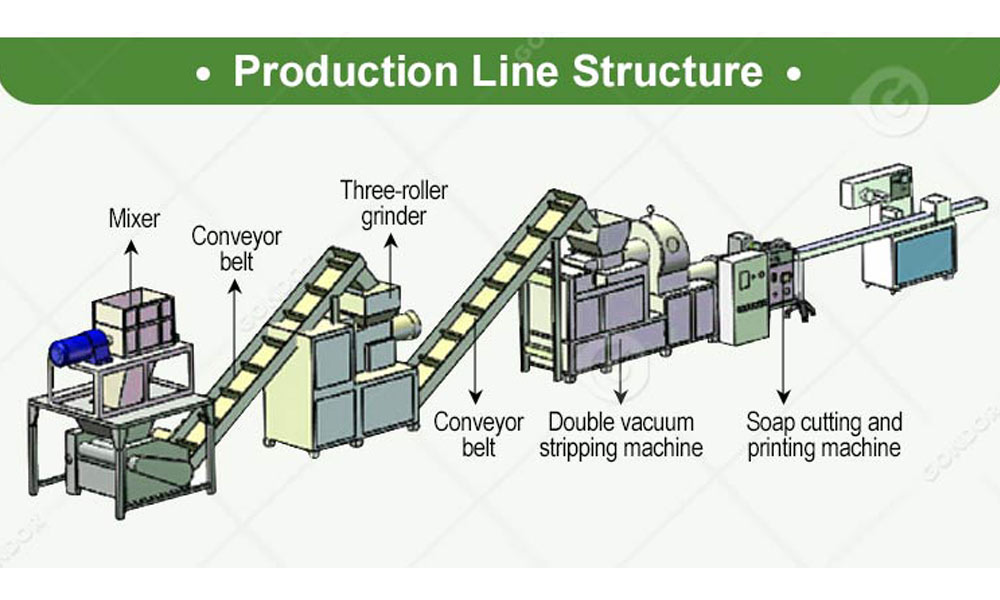

As the core production equipment in the daily chemical industry, our automatic soap production line integrates a modern automatic control system, covering various links from raw material mixing, grinding, layering, cutting, and stamping, among others. This enables efficient and standardized production, from soap particles to finished soap. This equipment is widely used in the manufacture of household soaps, special soaps for transparent soap, and customized soaps to meet the diverse needs of small and medium-sized processing plants, as well as large daily chemical enterprises.

| Name |

Voltage |

Power |

Yield |

Size |

| Mixer |

380V |

3kw |

100-300kg/h |

1230*650*1250mm |

| Three-roller mill |

380V |

5.5kw |

/ |

1100*960*1200mm |

| Twin-screw vacuum plodder |

380V |

5.5+7.5kw |

300-500kg/h |

3000*1080*1950mm |

| Soap block printing machine |

380V |

5.5kw |

20-200 pieces/minute |

/ |

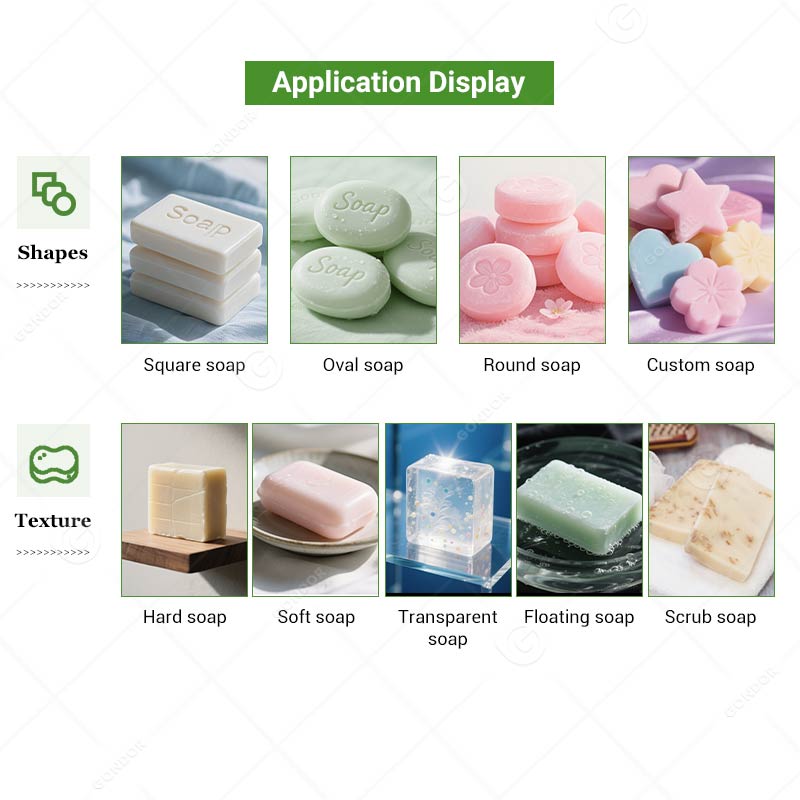

Automatic Soap Production Line with Versatile Applications

Our soap production line is suitable for many types of soap products, including:

- Square Soap

- Oval Soap

- Round Soap

- Customized-Shaped Soap

Whether it’s transparent soap, aromatherapy soap, or hotel soap, our equipment can stably output products with consistent quality, helping customers to seize market opportunities quickly.

Outstanding Production Efficiency of Soap Finishing Line

Continuous Production

The whole line adopts a modular automatic control system, which reduces manual intervention, realizes all-weather stable operation, and can produce thousands of bars of soap per hour, greatly improving the output efficiency per unit time.

Consistent Molding

Equipped with an advanced twin-screw vacuum layering machine, it ensures that the soap body is tightly pressed, smooth, and beautiful, and is suitable for high-speed molding and repeated pressing.

ccurate Cutting & Stamping

The block printing machine can realize 1g error control, and at the same time, quickly change the mold to complete the printing of LOGO, patterns, etc., to help you create brand-specific visual recognition.

Fine Grinding

Three-roller grinding machine can grind soap to 3-18 microns, improve texture and fragrance holding effect, and adopt a water cooling system to ensure long-term stable operation.

Variety of Shapes

Supports customization of different soap shapes and molds, and meets high-end customization needs such as e-commerce gift soaps, holiday theme soaps, and hotel small package soaps.

Eco-Friendly & Hygienic Design

Adopt a closed structure design to prevent external pollution and ensure that products meet GMP hygiene standards. And equipped with wastewater and waste gas treatment systems, they effectively reduce the impact on the environment and help customers achieve the goal of green production.

Complete Production Line Solution

In addition to the core soap production line, we can also provide you with the following equipment:

Soap Wrapping MachineInkjet PrinterSoap Dryer

Automatically complete single or multi-block packaging, with

heat shrink tunnel machine, cartoning machine and other equipment to choose from.

Print the production batch number, QR code, and other information on the surface of the package.

Improve the storage stability of soap, and meet the storage requirements in a high temperature and high humidity environment.

Contact us immediately to get customized solutions and product quotations, and jointly open a new era of efficient, intelligent, and environmentally friendly soap production!