Gondor Automatic Tray Arranging Machines

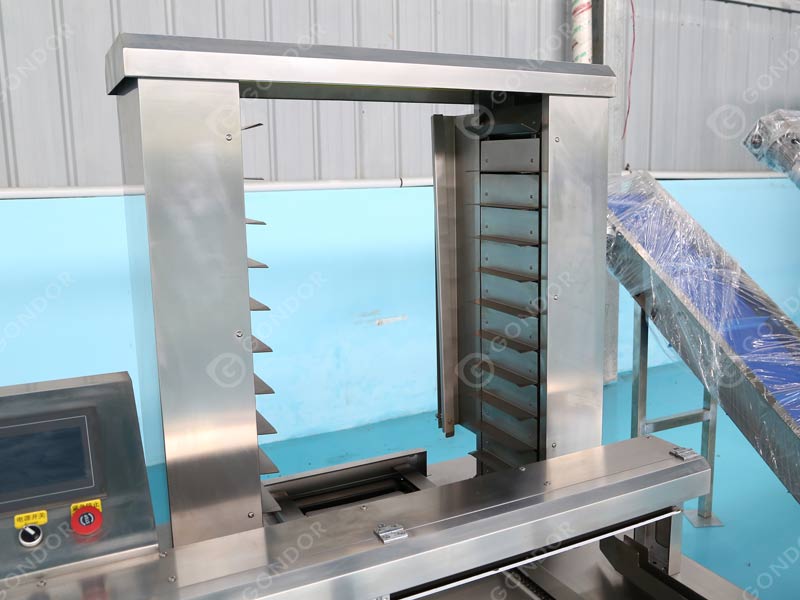

Automatic tray arranging machine is a device that is eminently suitable for large-scale food production. For instance, it performs exceptionally well in the food industry and can accurately and quickly place various foods such as cakes, frozen foods, and snack foods neatly on trays or containers.

Moreover, it adopts advanced technology and operates stably, thereby ensuring the accuracy of plate placing. Additionally, it is easy to operate and can greatly improve production efficiency and reduce labor costs. The sturdy and durable material enables it to adapt to long-term and high-intensity work. As a result, it is widely used in food processing plants, bakeries, and other places, providing strong guarantees for food production and packaging. Consequently, it helps enterprises improve product quality and market competitiveness.

Automatic Tray Arranging Machine Specification

| Model | GD-260 |

| Voltage | 220v/380v |

| Motor power | 1.2kw |

| Yield | 260/min |

| Size | 1.9*1.55*1.6m |

| Weight | 230kg |

Application Scenarios of Gondor Tray Arranging Machine

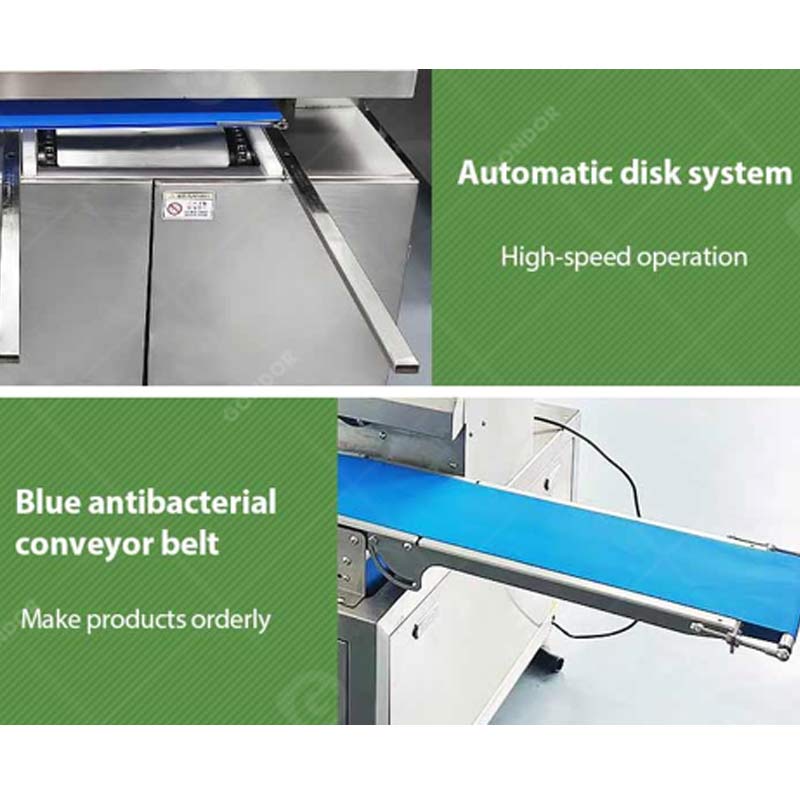

Significant Working Advantages of Gondor Automatic Tray Arranging Machine

It has efficient operating speed, greatly improves the working efficiency of the production line, can quickly complete the plate placing task, and is suitable for factory environments with high production requirements.

The equipment has extremely high accuracy and can accurately place items to the predetermined position, reducing manual adjustment time and ensuring production efficiency and consistency.

Support long-term continuous work without interruption due to fatigue or operational errors, ensuring stable and efficient operation of the production line.

Closely cooperating with other upstream and downstream production equipment, seamless integration of automated production lines can be achieved, improving the smoothness of the entire production process.

It can process a large number of items at the same time to meet the needs of large-scale production lines, greatly improve production capacity, and is suitable for large-scale production operations.

Supports multiple lining methods such as parallel or cross, and can customize specialized models for baking trays according to special specifications.

Reducing reliance on a large number of manual operations not only lowers labor costs, but also enhances the automation level and overall efficiency of the production line.

Equipped with advanced PLC control system and built-in storage program, parameters can be adjusted quickly to adapt to diverse production needs and improve flexibility.

Gondor Automatic Tray Arranging Machine Makes Production More Efficient

Gondor automatic tray arranging machine is your top choice for boosting production efficiency and cutting labor costs. It offers high-speed, precise plate placement, supports multiple lining methods, and integrates seamlessly into production lines for long-term stable operation. With its intelligent adjustment system, the machine adapts to various product requirements, minimizing switching time and enhancing overall efficiency. By choosing Gondor, you’ll enjoy a streamlined, one-stop solution for efficient production, helping your business move toward a smarter, more automated future.