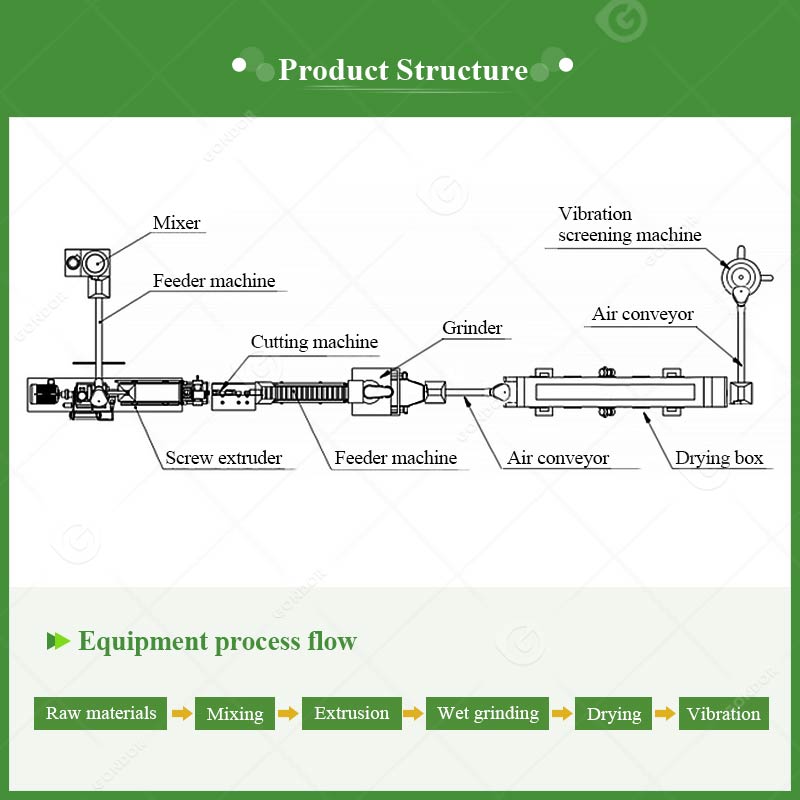

Bread crumbs production line is very important for modern food processing, which can improve the taste of fried chicken, seafood and desserts. Our fully automatic system runs continuously, and mixing, drying, and screening are completed with minimal manual operation. This improves efficiency and ensures product stability. It produces bread crumbs, needles, rotary cutting bread crumbs, and flexible adjustments to meet market demand. All parts that come into contact with food are made of food-grade materials, which meet safe and reliable international hygiene standards.

|

Name |

Power(kW) | Voltage | Size(mm) | Capacity(kg/h) |

| Mixer | 4kw | 380V | 800*500*700 |

20-50kg/once |

|

Feeder machine |

2.1kw | 3600*800*2100 | / | |

| Screw extruder | 35kw | 2500*800*1800 |

100-150kg-h |

|

|

Cutter |

1.5kw | 1200*800*1300 | / | |

| Feeder machine | 0.55kw | 2500*530*2400 | / | |

|

Grinder |

7.5kw | 800*1000*1680 | 200-300kg | |

| Air conveyor | 0.55 | 1800*500*2300 | / | |

|

Drying box |

38kw | 5500*1400*2200 | 200-300kg | |

| Vibration screening machine | 0.55kw | / |

200-300kg |

Applicable Products of Bread Crumbs Production Line

The bread crumbs production line is suitable for a wide range of food processing fields, especially for the production of the following products:

Core Advantages of Bread Crumb Making Machine

Matching with Other Food Processing Equipment

To optimize the food production line, the breadcrumb production line can be used with the following equipment to improve the overall production efficiency:

- Continuous Frying Machine – Suitable for the production of fried chicken, seafood, French fries, and other foods.

- Chicken Breading Machine – Used for surface treatment of chicken chops, fish chops, and other foods.

- Double Chamber Vacuum Sealer – Ensure that bread crumbs are packaged quickly, hygienically, and tightly.

Customize the Plan and Seize the Market Opportunity

Our bread crumbs production line improves efficiency, ensures stable quality, meets international food safety standards, and enhances the competitiveness of food processing plants. Contact Gondor Machinery for detailed information and expert support!