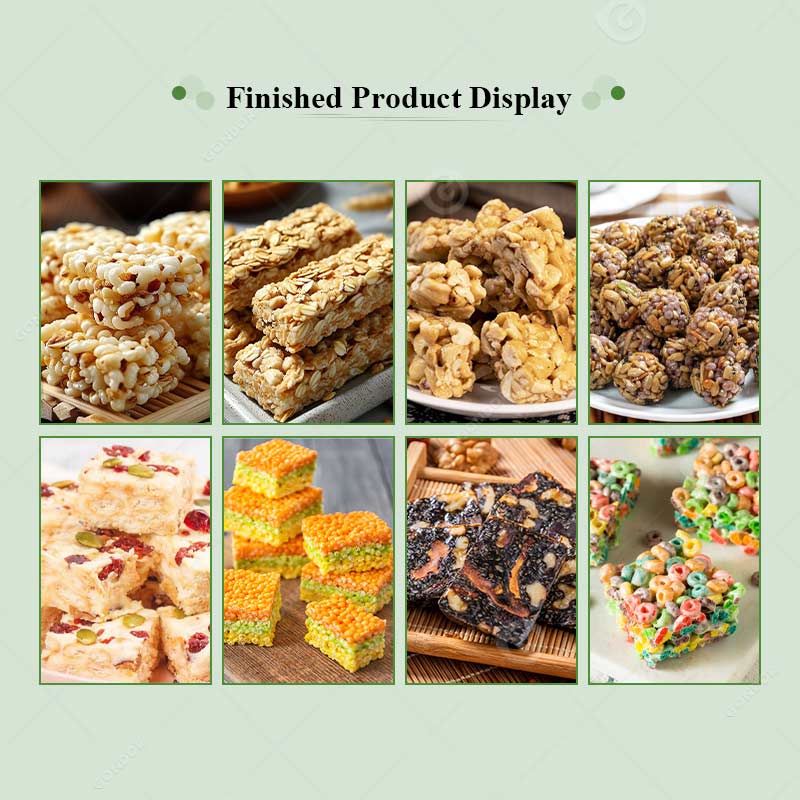

Our cereal bar production line uses advanced technology and is designed for global customers to provide a convenient nutritional supplement option. The fully automated production system covers raw material processing, mixing, forming, cutting, coating and packaging, ensuring efficiency, precision and rich nutrition. Intelligent equipment control enables unattended operation and greatly improves production efficiency. Advanced automatic tracking cutting structure and adjustable cutting speed reduce human interference, improve production stability and efficiency, and ensure final product quality.

|

Name |

Power(kw) | Voltage(v) | Weight(kg) | Size(mm) | Capacity(/h) |

| Food puffing machine

(optional) |

12.5KW | 380 | 200KG | 1050*950*1450 |

75KG |

|

Sugar pot (standard) |

40KW | 380 | 100KG | 1400*1000*1600 | 300L |

| Mixer machine (standard) | 2.5KW | 380 | 130KG | 1100*660*1900 |

80L |

|

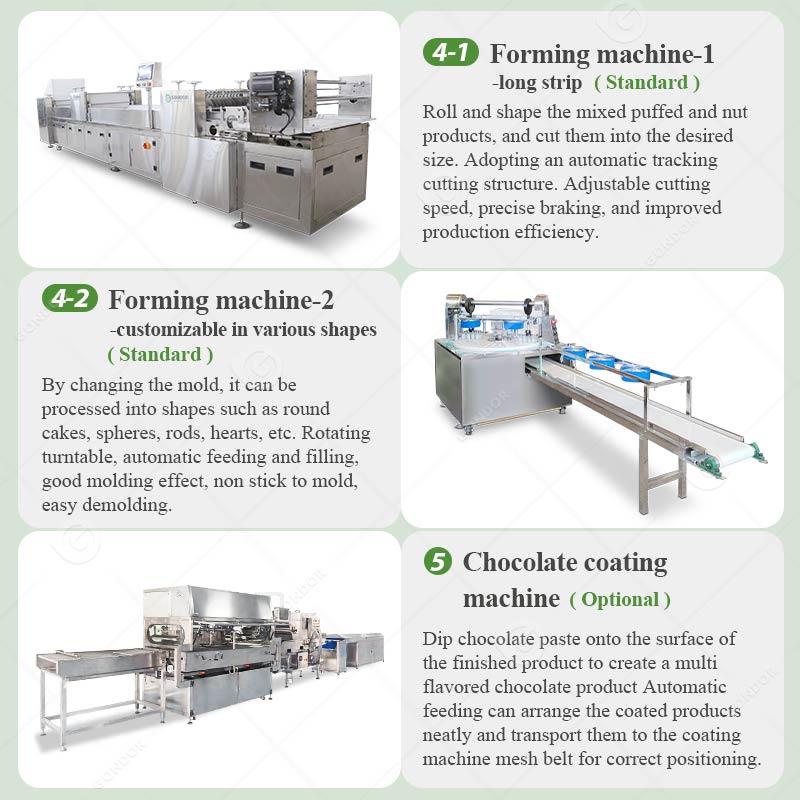

Forming machine-1 (long strip) (standard) |

3.7KW | 380 | 1350KG | 4100*1360*1200 | 200-400KG |

| Forming machine-2 (customizable in various shapes) (standard) |

Motor power 2.5KW Heating power 5KW A total of 7.5KW |

380 | 1200KG | 3960*1000*1500 |

200-400KG |

|

Chocolate coating machine (optional) |

2.5KW | 380 | 230KG | 3000*1080*1300 | 500KG |

| Packaging machine (optional) | 3.5KW | 220 | 150KG |

2400*500*400 1200*1700*900 |

350pcs |

Protein Bar Production Line Has a Wide Range of Application Markets

Our protein bar production line is suitable for a variety of market areas, including but not limited to:

Unique Technical Advantages of Energy Bar Machine

Using advanced servo motor technology, real-time adjustment of cutting length, ensuring uniform product, improving production efficiency and reducing downtime.

Servo motor improves cutting speed adjustability, reduces impact noise, and precise brake system ensures the cutting quality of each cereal bar.

Vertical and horizontal double blade design reduces friction and extrusion force, improving the uniformity and crispness of cereal bars.

Equipped with puffing machine, using liquefied gas or electric heating method to ensure that puffed grains are evenly heated and nutritious.

The coating machine automatically feeds to ensure uniform coverage of chocolate, improving taste and visual appeal.

Fully automatic packaging, supporting customized packaging film, up to 300 packs per minute, meeting large-scale production needs.

Fully Meet the Needs of Global Customers

Our cereal bar production line is suitable for companies of different sizes around the world. It supports flexible customization, improves production efficiency, reduces labor costs and provides high-quality products to meet diverse market needs. It also combines advanced technology to ensure that each production link is efficient and accurate. It is widely used in food manufacturing, fitness nutrition and healthy snacks, helping companies expand into the global market. For more information, please contact us or view other related equipment, such as the chocolate enrobing machine and smart packaging machine.