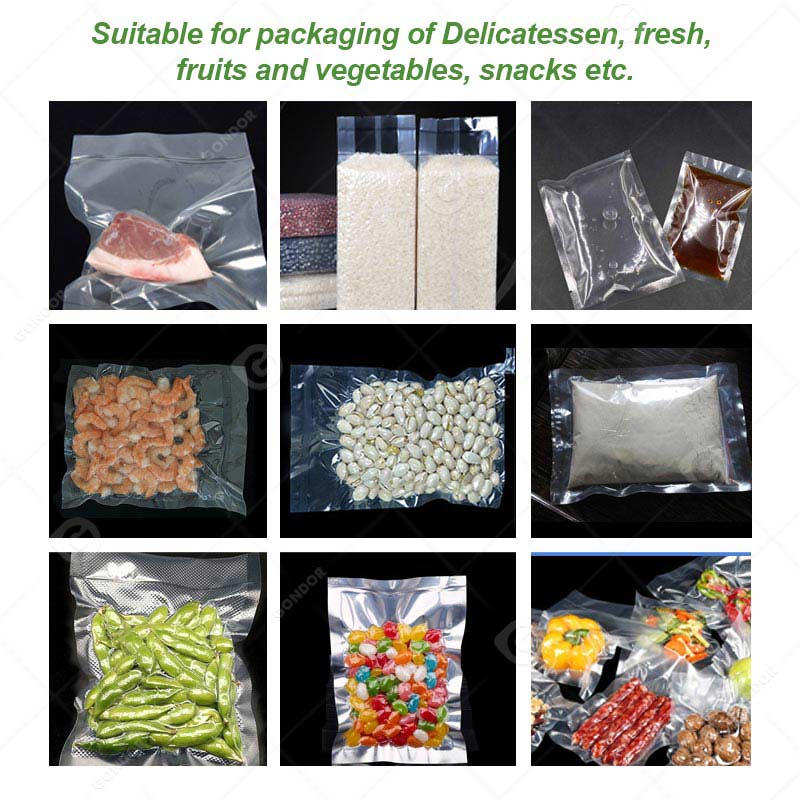

Double chamber vacuum sealer machine is an efficient and easy-to-operate small packaging device, especially suitable for the vacuum packaging and storage of food items such as cooked foods, fresh produce, fruits, vegetables, and whole grains. One of its main features is the dual-chamber design, which enables alternating operation between chambers, thereby greatly improving packaging efficiency. Additionally, the machine’s body is made entirely of 304 stainless steel, ensuring not only strength and durability but also easy cleaning and excellent anti-corrosion properties. Furthermore, the machine includes a high-efficiency industrial vacuum pump, allowing for fast and effective vacuuming. With its intelligent control panel, users can accurately adjust both vacuum and heat-sealing times, ensuring optimal sealing quality for different types of packaging bags.

| Model | GD-400 | GD-500 | GD-600 | GD-800 |

| Size | 1100*500MM | 1200*600MM | 1300*700MM | 1700*900MM |

| Voltage | 220V/380V | 220V/380V | 220V/380V | 220V/380V |

| Power | 1.5KW | 2.2KW | 3KW | 4KW |

Application Market Scope of Gondor Group Double Chamber Vacuum Sealer

Double vacuum sealers are widely used in many industries due to their high efficiency and convenience. They can not only extend the shelf life of products, but also effectively prevent products from getting damp, oxidized or contaminated, thus ensuring product quality and safety. The application market mainly includes the following areas:

Significant Competitive Advantages of Gondor Double Chamber Vacuum Machine

The operation is simple and one person can complete the packaging process independently.

The two chambers work in turns. When one vacuum chamber is working, the other can place products in advance, greatly improving efficiency.

Multiple bags of products can be placed at the same time, suitable for batch packaging needs.

Equipped with a high-power vacuum pump, the vacuuming speed is fast and the effect is remarkable.

304 stainless steel body, resistant to corrosion and oxidation, easy to clean and ensures durability.

Display operation panel, visual data, vacuum and sealing time can be accurately adjusted.

Built-in air switch automatically cuts off power when the voltage is unstable or short-circuited to ensure safety.

Effectively prevent the contents of the package from oxidation, mildew, and moisture, and extend the storage period.

Gondor Double Vacuum Packaging Machine – Efficient Packaging, Quality Assurance

Double chamber vacuum sealer machine is specifically designed for various industries, including food, catering, agriculture, and medicine. With its innovative dual-chamber rotating working mode, combined with intelligent control and a powerful vacuum system, it achieves a highly efficient packaging process. Additionally, the full 304 stainless steel body ensures not only durability but also resistance to corrosion and ease of cleaning, making it adaptable to long-term operation in diverse environments. Furthermore, it can package multiple product bags simultaneously, significantly boosting packaging efficiency, extending product shelf life, and preventing issues such as oxidation, mildew, and moisture damage. The safety features include an automatic power-off air switch, ensuring the safety of both equipment and operators. The Gondola vacuum packaging machine allows for longer product storage and worry-free packaging!

Send an inquiry now to receive the latest quote and boost your packaging efficiency!