Precision Cooking for Superior Results

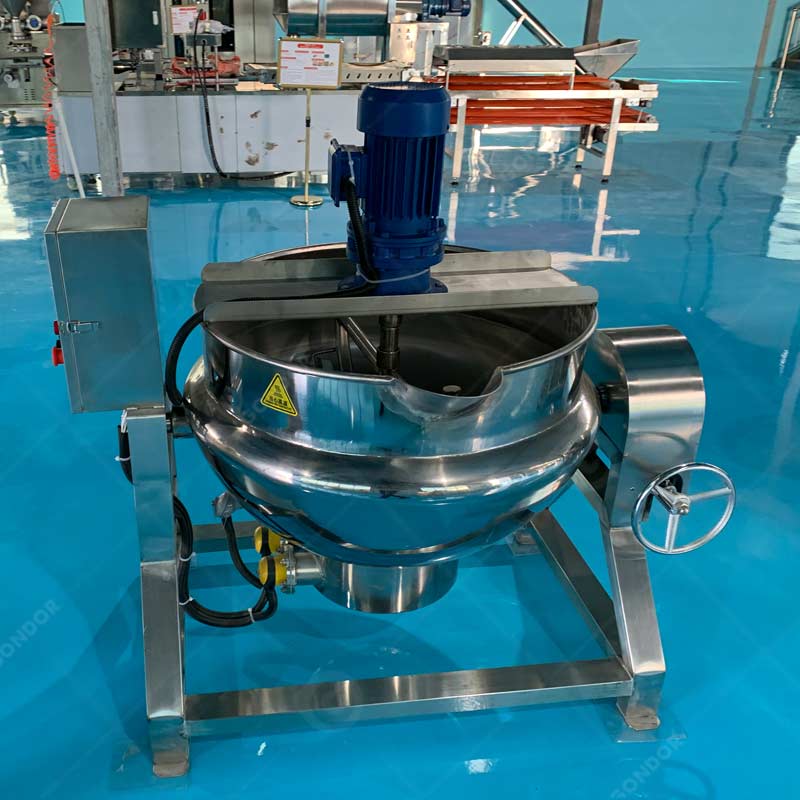

Gondor double jacket steam kettle stands as an essential tool for modern food production, specifically engineered for boiling candy with exceptional consistency. Crafted from high-grade food-safe materials, it offers superior corrosion resistance and optimal heat distribution, ensuring both product purity and operational efficiency. This durable foundation makes it ideal for demanding confectionery processes.

Beyond its robust construction, the kettle integrates an advanced stirring mechanism, precise heating system, and intuitive controls to create a perfectly managed cooking environment. This synergy allows manufacturers to reliably produce everything from delicate sugar syrups to thick savory bases, guaranteeing uniform taste and texture batch after batch. Suitable for candy factories, food plants, and large-scale kitchens, it delivers the control needed for premium output.

|

Model |

Capacity | Size | Pot mouth diameter | Electric heating power | Gas heating power |

| GD-BYJKM-50 | 50L | 1300*750*900mm | 600mm | 12kw |

0.75kw |

|

GD-BYJKM-100 |

100L | 1400*850*900mm | 700mm | 18kw | 1.1kw |

| GD-BYJKM-200 | 200L | 1500*950*900mm | 800mm | 24kw |

1.5kw |

|

GD-BYJKM-300 |

300L | 1600*1050*900mm | 900mm | 24kw | 1.5kw |

| GD-BYJKM-400 | 400L | 1700*1150*900mm | 1000mm | 36kw |

1.5kw |

|

GD-BYJKM-500 |

500L | 1750*1250*950mm | 1100mm | 36kw | 2.2kw |

| GD-BYJKM-600 | 600L | 1850*1350*950mm | 1200mm | 48kw | 2.2kw |

Main Service Industry Fields of Double Jacketed Steam Kettle

Used to cook various dishes, such as stewing, boiling soup, boiling sauces, etc. It can also make special delicacies, such as hot pot base, brine, etc., to provide unique flavors for restaurants.

Processing various canned foods, condiments, jams, etc. Suitable for large-scale production, improving production efficiency and reducing production costs.

Boil syrups, chocolates, etc. to make various special candies and pastries, add unique flavors, improve product quality and grade, and meet the different needs of consumers.

In the pharmaceutical process, it can be used to boil Chinese medicine ointments, decoctions, etc., which can improve the efficacy of drugs and ensure the quality and safety of drugs.

The equipment can be used to boil the paste raw materials in daily chemical products such as toothpaste to reach the appropriate temperature and concentration to ensure the quality and stability of the products.

Such as honey paste, donkey-hide gelatin paste, etc., the heating temperature and time can be adjusted according to different health care product needs to meet the diverse needs of the market.

Unique Characteristics of the Gondor Steam Jacket Kettle

Complete Candy Production Line Integration Solution

To establish a comprehensive gummy candy production line, this equipment seamlessly integrates with the following components:

- Sugar Melting Pot: Pre-dissolves raw materials like granulated sugar. Directly connects to the boiling pot via piping for automated material transfer.

- Ingredient Dosing System: Precisely adds colorants, flavorings, and other additives to ensure consistent recipes.

- Candy Depositing Machine: Directly receives molten sugar syrup for precise, metered molding.

- Cooling Tunnel: Connected downstream to rapidly chill and set molded candies.

- Packaging Machine: Interfaces with the cooling tunnel to complete automated candy packaging.

- Intelligent Control System: Centralized control panel enables unified adjustment of all line parameters, achieving fully automated production from sugar melting, boiling, molding, to packaging.

Gondor’s High-Quality Double Jacket Steam Kettle – The First Choice for Sweet Manufacturing

Our double jacket steam kettle is of excellent quality. Precise temperature control and uniform heating ensure perfect sugar boiling. Food-grade material, safe, hygienic and easy to clean. Suitable for candy, pastry and other industries. Efficient boiling brings you wealth. Choose Gondor’s ,double jacketed steam kettle to start your sweet career journey.