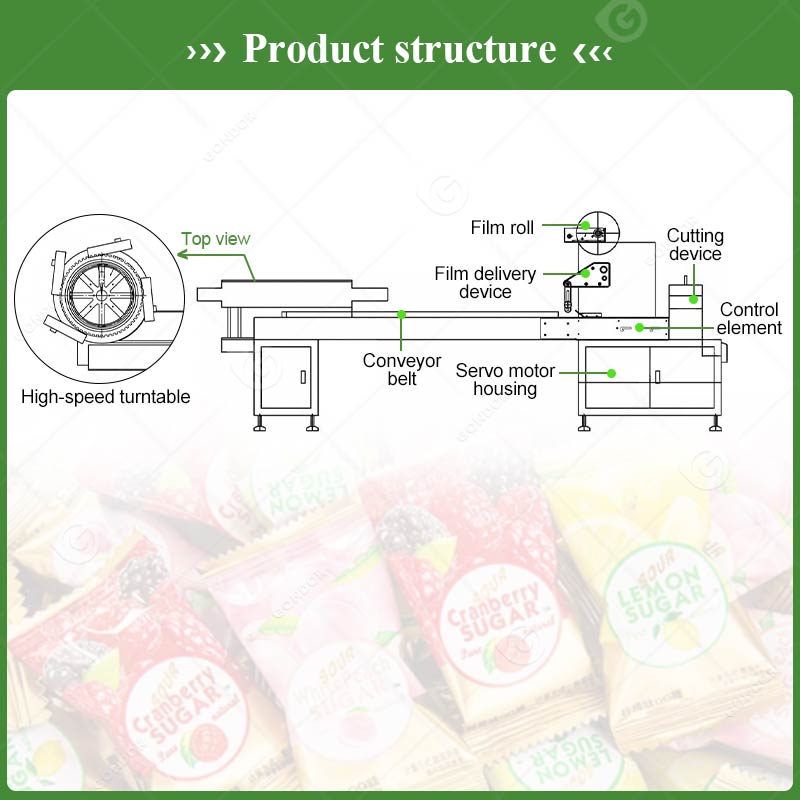

Gondor High-Speed Candy Pillow Packing Machine Introduction

The Gondor high speed pillow candy wrapping machine utilizes a continuous motion principle and an intelligent photoelectric tracking system to achieve rapid positioning and precise sealing, while its food-grade stainless steel structure and flexible modular design ensure high hygiene standards and stable switching between various shapes like hard candies and chocolates, offering a sophisticated automatic pillow pack machine solution that combines high-efficiency output with premium visual presentation for any integrated candy packing machine production line.

Gondor Candy Full Automatic Pillow Packing Machine Models

To meet the dual demands of global confectionery manufacturers for high output and packaging aesthetics, Gondor Machinery has leveraged its profound industrial design heritage and expertise in automated processes to develop this series of industry-leading high-efficiency intelligent candy packaging machine, designed to provide precise, reliable, and forward-looking technical support for enterprises of all production scales.

| Model | GD-HCPM-350 | GD-HCPM-800 | GD-HCPM-1000 |

| Packaging Speed (Granules/Minute) | ≤350 | ≤1000 | 50-900 |

| Packing Specification | Rectangular, Square, Circular, Elliptical and Irregular Shapes | ||

| Packaging Paper Length | 50-320mm | 45-80mm | 50-120mm |

| Total Power | 5kw | 6kw | 3.7kw |

| Power Supply | 220V Single-Phase | ||

| Overall Dimensions | 4200*1300*1600mm | 3800*1300*1600mm | 3850*1100*1800mm |

| Machine Weight | 580kg | 860kg | 720kg |

How to Prevent Candy from Sticking in a High-Speed Flow Wrapper

To prevent candy from sticking in a high-speed flow wrapper, you must combine environmental control with mechanical optimization. Maintaining a cool, low-humidity production room (typically below 40% RH) is the first line of defense to prevent candies from becoming hygroscopic and tacky. On the machine itself, using Teflon-coated feeders or dimpled stainless steel surfaces significantly reduces the contact area and surface tension.

Furthermore, ensuring perfect synchronization between the vibratory feeder and the film speed prevents product congestion, while antistatic devices and cooling systems near the sealing rollers help maintain the candy’s structural integrity and prevent heat-induced sticking during the high-speed wrapping process.

Versatile Packaging Solutions for Diverse Candy Types

- Hard candy: Achieves high-speed single-piece or chain-pack wrapping while preserving crunchiness and preventing moisture absorption.

- Soft candy: Equipped with sensitive sensors to ensure soft-textured candies are packaged without deformation or surface sticking.

- Toffee: Optimized for high-viscosity products, providing smooth feeding and airtight seals to prevent the toffee from sticking to the film.

- Flake candy: Features a gentle handling system designed to minimize the breakage rate of fragile, thin-sliced confectionery.

- Chocolate: Utilizes temperature-controlled or cold-sealing technology to prevent the chocolate from melting during the heat-sealing process.

- Marshmallow: Supports gas-flushing (nitrogen) capabilities to maintain the fluffy shape of the marshmallow and extend its shelf life.

- Lollipop: Specially designed holding slots accommodate both the candy head and the stick for a secure and neat pillow-style finish.

- Prunes (Preserved Fruit Candy): Uses anti-corrosion materials and specialized belts to handle the high moisture and sugar content typical of preserved fruits.

Gondor High-Speed Candy Pillow Packing Machine Application Industries

Provides high-speed, airtight packaging for various candies, ensuring product hygiene and maintaining flavor and texture.

Ideal for individual or multi-pack wrapping of biscuits, chocolate bars, and wafers to keep them crisp and fresh.

Ensures precision and sterile packaging for throat lozenges, herbal tablets, and medical gummies under strict safety standards.

Efficiently wraps small hospitality items like peppermint candies, sugar cubes, and compressed towels for professional presentation.

Gondor High-Speed Candy Pillow Packing Machine Features

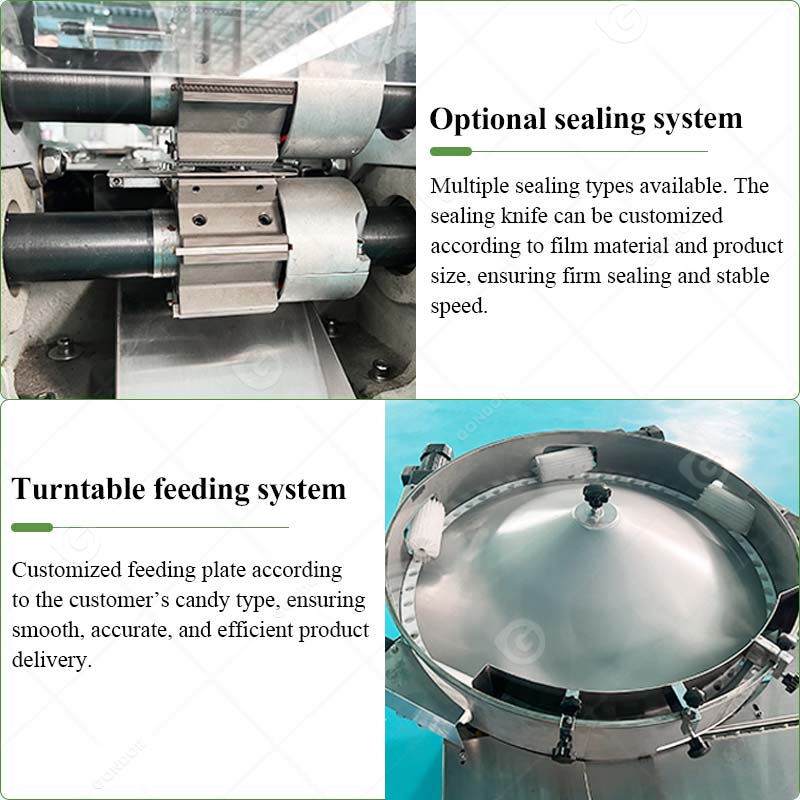

Automatically detects product length and cuts precisely without manual adjustment, saving time and packaging film.

High-sensitivity color mark detection ensures precise sealing and cutting positions.

Maintains stable heat sealing for various packaging materials.

Automatic error detection with clear fault display for quick troubleshooting.

Stops at the preset position to prevent film waste and cutter sticking.

All functions are software-controlled for easy adjustment and future upgrades.

Can One Candy Pillow Packing Machine Handle Different Candy Sizes

Basically, modern pillow packing machines are very “smart” and flexible, so one machine can definitely handle several different sizes of candy. Think of it like an adjustable phone stand—if you want to switch to a different size, you just change some settings on the touchscreen (like the bag length) and manually adjust the “forming box” (the part that shapes the bag) so that candies of different widths can slide through smoothly.

However, if the two candies are vastly different in size—for example, one is as tiny as a mint and the other is as large as a full-size chocolate bar—you might need to swap out a few key parts, such as the specific “forming shoulder” or the feeding pushers. This ensures the candy stays centered and doesn’t get jammed or wrapped crookedly when the machine is running at high speeds.