Hydraulic Sausage Filler Machine

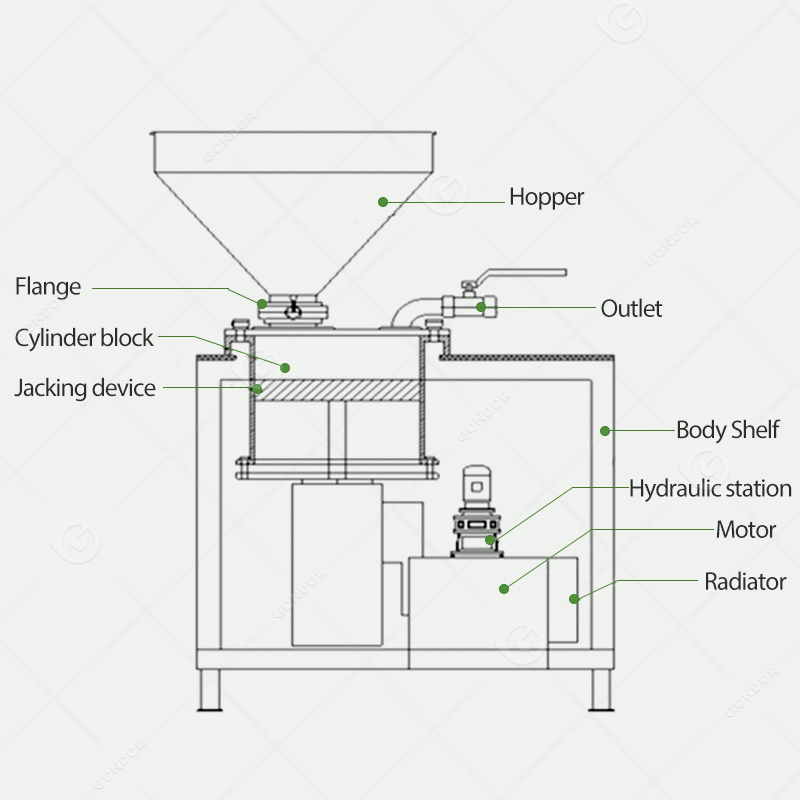

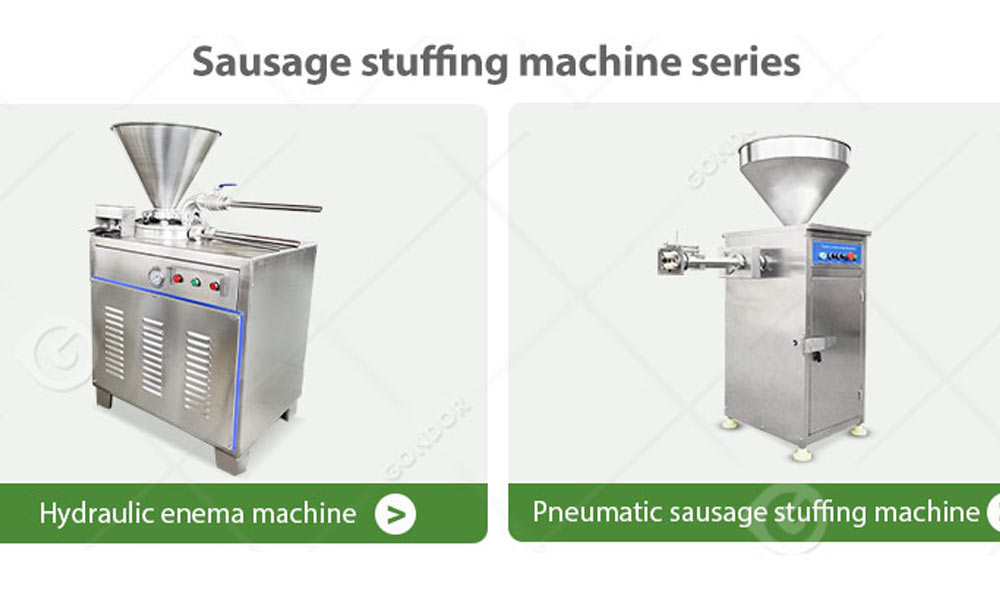

Hydraulic sausage filler machine is a common sausage stuffing equipment. It is mainly composed of a hopper, a hydraulic system, a sausage stuffing tube and other parts. It adopts a hydraulic station pumping sausage stuffer, which is widely used and has a low maintenance rate, and is deeply loved by customers. Moreover, the equipment is easy to operate, has a fast and uniform sausage stuffing speed, and can greatly improve production efficiency. It is suitable for the processing and production of various types of sausages, and can be widely used in both small food processing plants and large enterprises. In addition, its precise control ensures the stable quality of each sausage, which brings convenience to the food processing industry and is a powerful assistant in sausage making.

| Model | Voltage(v) | Output(kg/h) | Power(kw) | Dimension(mm) | Weight(kg) |

| GD-30 | 220/380 | 300 | 2.2 | 800*650*1280 | 240 |

| GD-32 | 220/380/110 | 300 | 0.75 | 1500*565*1300 | 240 |

| GD-50 | 220/380/110 | 500 | 1.5 | 1020*730*1500 | 400 |

Main Service Industries of the Gondor Hydraulic Enema Machine

Maximizing Output with a Hydraulic Sausage Stuffer

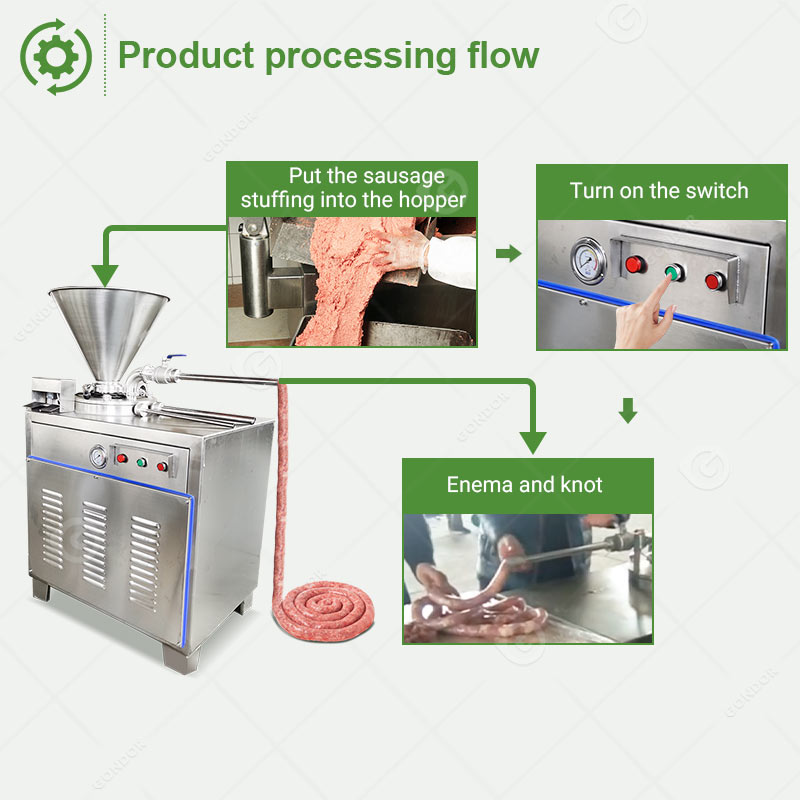

Integrating a hydraulic sausage stuffer into your production line brings unparalleled efficiency and consistency. This type of sausage stuffer machine excels in handling large volumes of diverse mixtures—from fine-emulsion hot dog fillings to coarser, chunkier sausage recipes—with minimal product loss or air pockets. The steady, powerful pressure of the hydraulic sausage filler machine ensures that each casing is filled uniformly, resulting in sausages that have a consistent texture, appearance, and weight. This not only boosts your output but also significantly enhances the overall quality and marketability of your final products.

Excellent Efficiency Advantage of Gondor Sausage Fill Machine

Mobile body design, easy and flexible operation. The machine operates with low noise and high efficiency. Reduced labor intensity and improved work efficiency.

Adapt to casings of different diameters and lengths, as well as various types of fillings. It can meet the needs of different customers and provide more choices and flexibility for food processing companies.

The part of the equipment that comes into contact with materials is made of 304 stainless steel, which is safe, hygienic, and corrosion-resistant. Easy to clean and have a long service life.

Adopting hydraulic drive, it can provide strong thrust and greatly improve filling speed. It can complete a large amount of sausage filling work in a short period of time, meeting the needs of large-scale production.

It has good continuous operation ability and can continuously perform filling work. No need to stop frequently for adjustment or maintenance. It is suitable for long-term production tasks and improves production efficiency.

Frequently Asked Questions

High-Efficiency and Quality Choice – Gondor Hydraulic Enema Sausage Filler Machine

The Gondor Hydraulic Sausage Filler serves as the perfect endpoint in your sausage production line. It takes in fillings prepared by a meat grinder or emulsified by a meat bowl cutter, using hydraulic power for fast and precise stuffing that ensures every sausage is plump and consistent. Whether processing mixtures from a vacuum meat mixer for enhanced flavor or operating standalone, it guarantees high-efficiency output. Choosing Gondor means selecting a seamless, end-to-end solution that effortlessly transforms raw ingredients into premium sausage products.