Lollipop Machine: Smart, Efficient Production

Lollipops, known for their vibrant colors and sweet taste, are popular among consumers of all ages, with demand continually rising. To meet the growing need for efficient, high-quality lollipop production, Gondor Machinery has developed our cutting-edge lollipop candy making machine for sale worldwide. Moreover, this lollipop machine offers advanced automation, intelligent control systems, and user-friendly operation, which enable manufacturers to produce a wide variety of lollipops with consistent quality in different shapes, flavors, and colors. Additionally, with flexibility and efficiency, this candy machine helps businesses increase production capacity and product diversity. Gondor Machinery also provides tailored solutions and comprehensive technical support, which can ensure seamless integration and long-term success for candy producers. Contact us for more!

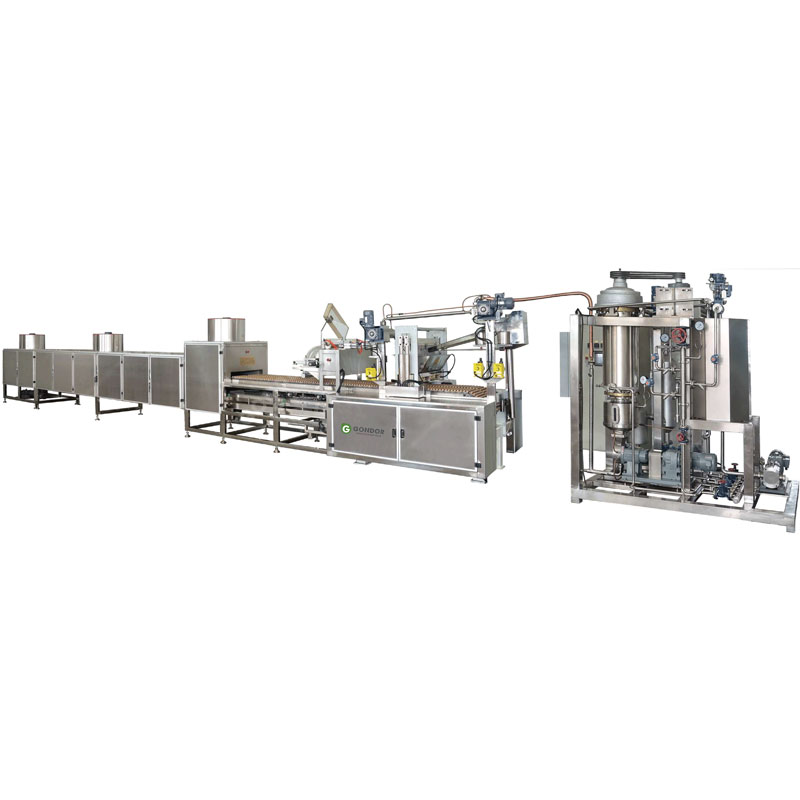

Efficient Lollipop Candy Making Machine for Sale in Gondor

What is a Lollipop Candy Making Machine?

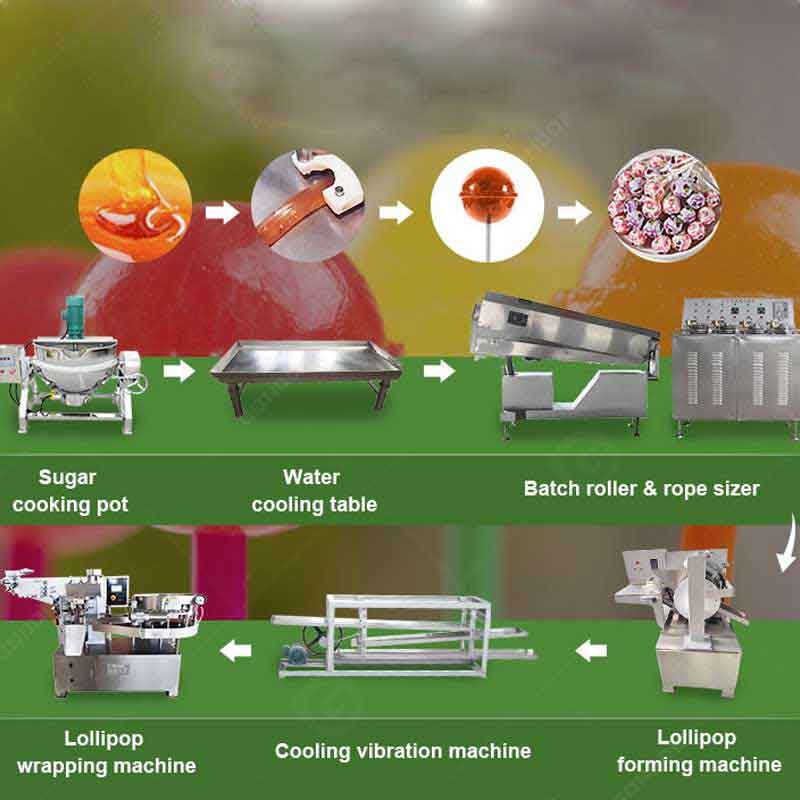

A lollipop candy making machine is an automated food processing machinery that is designed to produce lollipops by mixing ingredients like syrup, glucose, flavors, and colors, followed by shaping them into lollipops. At the same time, the lollipop making machine handles the entire process, from raw material handling to packaging, which can ensure the efficient large-scale production.

Key Components and Features:

- Mixing System: Accurately blends ingredients.

- Heating System: Precisely controls the temperature for uniform syrup.

- Molding/Depositing System: Shapes lollipops through molding or depositing techniques.

- Cooling System: Quickly solidifies the lollipops.

- Packaging System: Automates packaging, reducing manual labor.

Production Scale:

- Small-scale: Suitable for startups and small operations.

- Medium-scale: Ideal for growing businesses looking to boost production.

- Large-scale: Designed for high-volume, industrial-level production.

Different Types of Lollipop Making Machines Offered By Gondor Machinery

At Gondor machinery, there are two main types of lollipop candy making machines including the deposited lollipop candy machines as well as the molded lollipop making machines, which are mainly designed to meet various customer needs. As for the deposited lollipop making machine, it uses high-precision depositing technology, which allows for the creation of complex shapes and uniform textures. Therefore, the lollipop candy machine is ideal for producing innovative lollipops with fillings or mixed flavors. On the other hand, the molded lollipop candy machine utilizes mold-pressing technology to quickly and efficiently produce standard-shaped lollipops, which is perfect for large-scale industrial production. That is to say, whether for small artisanal workshops or large candy factories, our company can provide efficient and reliable solutions to enhance production efficiency and product quality.

Introduction to Deposited Lollipop Making Machine

As an advanced candy making machine, our deposited lollipop making machine adopts cutting-edge automation technology, which can significantly improve the efficiency of lollipop production. Moreover, this lollipop candy making machines can achieve the fully automated production from raw material handling to the packaging of final products – lollipops in different shapes and flavors. In addition, the lollipop machine from our factory with a cutting-edge control system can precisely control over the production parameters to guarantee the the stability and consistency of lollipop quality. What’s more, the machines can offer great versatility to produce a wide range of attractive lollipops, which cater to diverse market demands. Contact us today to explore how our lollipop making machines can enhance your production line and boost your business!

Overview of Gondor Molded Lollipop Candy Machine

Our molded lollipop candy machine is a cutting-edge solution designed to streamline the production of lollipops using molding technology. This advanced machine enables efficient, large-scale production with consistent quality, which makes it an ideal choice for manufacturers looking to enhance their output. Beside, the molding lollipop candy machine automates the entire process, from raw material handling to final product packaging, and can produce lollipops in various shapes and sizes. With a sophisticated control system, the production parameters can be controlled precisely, such as temperature, pressure, and timing, which lead to the perfect molding of each lollipop. Moreover, this machine offers excellent versatility and can cater to the diverse needs of the candy market. So. The molded lollipop candy machine can elevate your lollipop production and boost your business!

Comparsion Between Deposited and Molded Lollipop Making Machine?

What is a Deposited Lollipop Making Machine?

As evident from the name, the deposited lollipop making machine is a kind of candy production line which is widely applied to produce lollipops by leveraging the process called candy depositing. And the lollipop machine for sale in Gondor group typically consists of a series of specially designed machines that enable the fully automated, efficient, large-scale production from raw materials to lollipops. Furthermore, these lollipop candy machines work together to significantly increase the production efficiency, reduce the labor costs, and ensure the product quality and consistency. As for many candy manufacturers, they choose this production line to streamline the process of creating lollipops by combining ingredients like sugar, glucose syrup, flavorings, and colorings, and then shaping the mixture into finished lollipops.

In addition, this lollipop machine can precisely deposit the liquid candy to the molds, which can promote the production of a high level of uniformity in the size, shape, and consistency of the lollipops. Obviously, as a professional manufacturer of food processing machinery, we accept customization for our food processing equipment, including this deposited lollipop making machine.

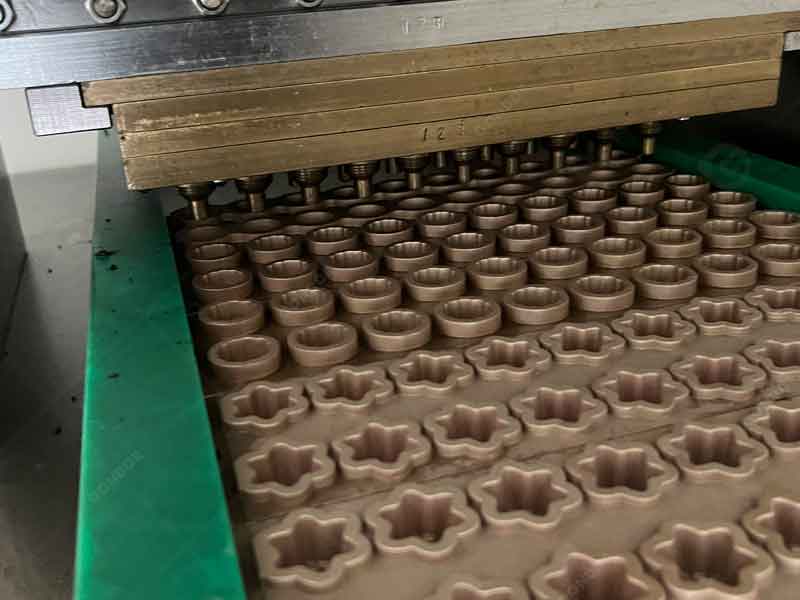

What is a Molded Lollipop Candy Machine?

A molded lollipop candy machine is a specialized production line designed to produce lollipops through the process of molding. Our production line utilizes mold-pressing technology to form lollipops by compressing candy mixtures into pre-designed molds, which offers high precision and consistency. The production process is fully automated, from blending ingredients like sugar, glucose syrup, flavorings, and colorings, to shaping the candy mixture into finished lollipops.

The molding process ensures that each lollipop is uniform in size and shape, which makes it ideal for large-scale industrial production where consistency is critical. Additionally, the molded lollipop making machine can be customized to produce a wide range of lollipop shapes, sizes, and designs. So, candy manufacturers buy lollipop candy machine to create unique and innovative products that stand out in the market. Like our deposited lollipop machines, the molded lollipop candy machine offers high efficiency, reduced labor costs, and enhanced product quality, which makes it an excellent investment for any candy production business. Contact us to discover more about how our molded lollipop machine can benefit your production line!

Deposited Lollipop Candy Making Machine in Gondor Factory

Buy Molded Lollipop Candy Making Machine in Gondor

Key Benefits of Lollipop Candy Making Machine for Sale

Looking for the perfect deposited and molded lollipop making machine for your business? As a confectionery manufacturer, choosing a high-efficiency and reliable lollipop making machine is essential to your production line’s success. What’s more, lollipop depositing and molding making machines are specifically designed for efficient, large-scale production, which will deliver consistently shaped, smooth-textured lollipops that cater to diverse market demands. Check below for the key benefits of our lollipop candy machines. Moreover, by incorporating these benefits into your lollipop production, our lollipop candy making machines can help you enhance productivity, reduce costs, and deliver high-quality lollipops that meet market demands.

High Production Efficiency

The lollipop candy making machines from Gondor machinery are optimized for the mass production, which will allow the production lines to produce large quantities of lollipops quickly without compromising quality.

Automated Production Process

Our lollipop making machine can handle every production process automatically, from raw material handling to packaging, which can significantly reduce manual labor and operational costs.

Consistent Quality

With precise control over production parameters, such as temperature, pressure, and timing, our lollipop machines ensure that every lollipop maintains the same size, shape, and texture.

Customization Options

To suit your unique manufacturing requirements, we offer customization for lollipop making machine. Furthermore, we offer flexible solutions for specific mold designs or specialized production features.

Advanced Control System

Equipped with cutting-edge control systems, the lollipop making machines allow for real-time monitoring and adjustments, which can ensure smooth operations and maintain consistent product quality.

Reduced Labor Costs

High automation reduces manual labor needs, cutting labor costs and improving efficiency. It ensures consistent productivity, leading to higher profitability and stronger market competitiveness.

Enhanced Durability

Constructed with premium, durable materials, the machines are designed for long-lasting performance. What’s more, they are built to endure heavy usage and high production demands for investors.

Energy Efficient

Our lollipop making machines are engineered with energy-efficient components to significantly reduce energy consumption without compromising performance, which can lower the operational costs.

Versatility in Shape and Size

Lollipop candy machines offer the flexibility to produce a diverse range of shapes and sizes, which enables candy factories to cater to different consumer preferences and evolving market trends.

Compact Design

Built with a compact, space-saving structure, our lollipop candy machines ensure efficient use of space, which can integrate seamlessly into various production environments without the need for expansive factory space.

Improved Hygiene and Safety

Built with food-grade materials and designed with easy-to-clean features, our lollipop candy machines adhere to strict hygiene and safety standards, which can ensure a safe production environment.

User-Friendly Operation

Advanced lollipop machines feature intuitive control panels and automated processes, which is easy to operate with minimal manual intervention. Even less experienced staff can use them efficiently, which can reduce errors and boosting overall productivity.

Expand Your Candy Business with Gondor Multi-functional Lollipop Making Machines

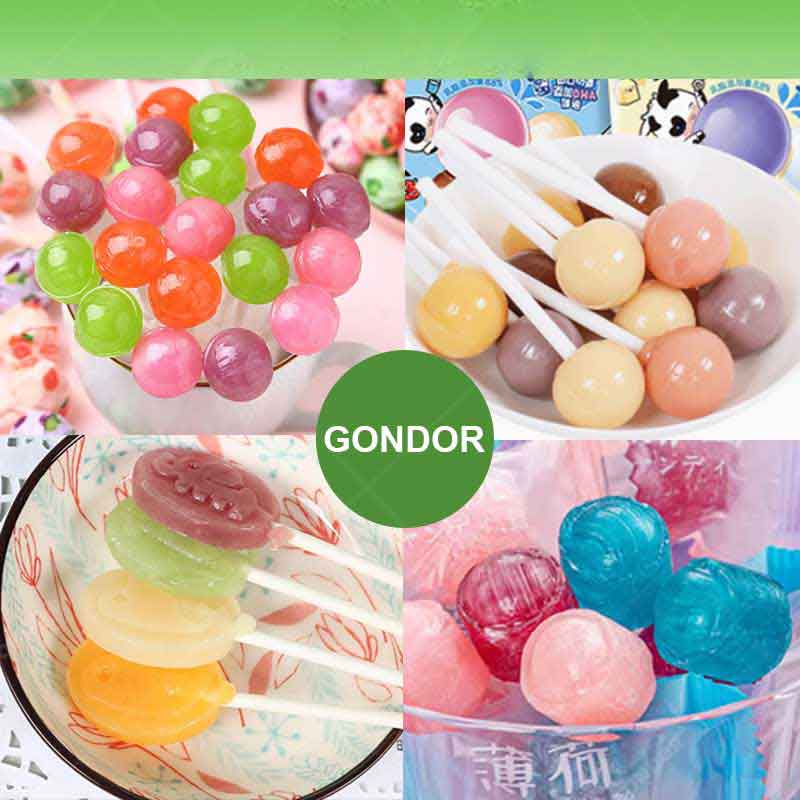

Except for the traditional round lollipops, Gondor machinery offers the multi-functional lollipop candy making machine. With our multi-functional lollipop making machines, businesses can significantly expand their product offerings and rapidly introduce innovative, eye-catching lollipops to the market. What’s more, because of the diverse production capability, our lollipop machine for sale can help meet varying consumer demands and enhance their competitive position in the candy industry. Here is a brief introduction to our multi-functional lollipop making machines:

Flexible Production for Various Flavors

Our lollipop candy machine is designed to accommodate different recipes and ingredients, which can allow the production of lollipops in various flavors such as fruit, cream, chocolate, and more. With simple adjustments, candy manufacturers can quickly switch between recipes to meet the growing demand for new and exciting flavors in the market.

Variety of Shapes to Attract Consumers

In addition to producing round lollipops, the lollipop making machines can create lollipops in a wide range of shapes, such as stars, hearts, animals, and other creative designs. Moreover, these lollipops of unique shapes can appeal to different age groups, especially children and teenagers, which can make the final products (lollipops) stand out on store shelves.

Versatile Color Combinations

The lollipop machine in Gondor group also supports the production of multi-colored lollipops as well as layered designs, which can help global customers produce visually appealing, vibrant lollipop candies. Therefore, this flexibility in color choices enhances the shelf presence of lollipops, which can make them more attractive to consumers.

Filled Lollipops for Enhanced Taste

Beyond the traditional solid lollipops, Gondor lollipop candy making equipment is capable of producing lollipops filled with various fillings like fruit jams or chocolate, which enhances the flavor complexity and delivers a richer, more delightful, multi-layered experience for consumers. Thus, with the lollipop machines from Gondor, businesses can stand out in the market.

Customized Production Solutions

Gondor Machinery provides customized production solutions and equipment configurations for lollipop candy machines, which can meet the specific customer needs. So, our lollipop making machine can create unique, brand-tailored candy products. With the flexible machines, candy factories can quickly adapt to market trends, which gives them a competitive advantage.

Automation and Smart Technology – Enhancing Efficiency in Lollipop Making Machines

Gondor machinery, as a professional food processing manufacturer, provides quality and efficient lollipop candy machines that has significant advantages in automation and smart manufacturing. Through fully automated processes, the lollipop machines can minimize manual intervention, reduce labor costs, and boost production efficiency. At the same time, the lollipop making machine features an intelligent control system that monitors key parameters in real-time, which can ensure the stable production and consistent product quality. Additionally, these lollipop candy making machines seamlessly integrate with smart factory systems, which can enable the remote monitoring and data analysis to optimize production management. With intelligent fault detection and maintenance alerts, our lollipop making machines can help prevent unexpected issues and extends its lifespan, which can meet the demands of modern food processing equipment for sale in the market.

How to Choose the Suitable Lollipop Candy Making Machine?

Selecting the appropriate lollipop making machine is a critical step in ensuring efficient production and high-quality lollipops. Moreover, the decision of choosing lollipop machines impacts not only operational costs but also the scalability and flexibility of a business. Now, in the candy market, there is a wide range of lollipop making machines available, and each offers different capabilities and features. So, it’s important to consider several key factors when selecting lollipop candy machines. In addition, by evaluating the production capacity, level of automation, space requirements, and other essential elements, customers can make a well-informed decision to realize their business goals and ensure the long-term success. Below are some critical aspects to consider when choosing the right lollipop machine.

Production Capacity

Evaluate the daily production volume based on market demand and business size. Then choose a lollipop candy machine that can meet your required capacity, which is typically measured in lollipops per hour. Besides, lollipop making machines with adjustable speeds are useful for businesses with fluctuating demand.

Level of Automation

Candy factories can select lollipop machines between manual, semi-automatic, or fully automatic machines which are based on your budget and labor availability. What’s more, fully automatic lollipop candy machines, though costlier, reduce labor expenses and increase efficiency, which are ideal for large-scale production.

Cost and Return on Investment

Choose a lollipop making machine that fits your budget while providing strong long-term value. Meanwhile, consider total costs, including energy, maintenance, and labor, which can ensure a solid return on investment. Thus, higher efficiency and reduced operating expenses contribute to faster payback and sustained profitability.

Energy and Environment

Choose energy-efficient lollipop making machines to reduce long-term operational costs and meet local environmental regulations on waste and emissions. Additionally, investing in eco-friendly lollipop machines not only minimizes environmental impact but also enhances your brand’s reputation among eco-conscious consumers.

Maintenance & After-Sales Support

Select lollipop candy making machines that are easy to clean and maintain, which can reduce the downtime. At the same time, verify the food processing and packaging equipment supplier offers reliable after-sales service support and warranties to ensure quick resolution of technical issues and parts availability.

Versatility of Lollipop Machines

If you plan to produce multiple lollipop shapes or flavors, choose a multi-functional lollipop making machine. Besides, lollipop candy machines that can switch molds or recipes easily offer flexibility and adaptability to market changes. Additionally, it helps streamline production processes, making it easier to introduce new products and follow consumer trends.

Space and Layout

Consider the space available in your candy production line before choosing a lollipop making machine. In addition, high-capacity lollipop candy making machines need more footprint and space requirements, while compact lollipop machines suit smaller factories. You had better ensure the machine fits smoothly into the production line layout.

Hygiene and Food Safety Compliance

Ensure the lollipop machine meets food safety standards, such as using stainless steel to prevent contamination. Easy-to-clean and disinfect lollipop candy machines are essential for maintaining hygiene and complying with regulations like GMP, which can ensure both product safety and efficient production in the long term.

Brand and Reputation

Buy lollipop candy machines from reputable suppliers with proven experience and positive customer feedback. Moreover, a reliable supplier not only offers better after-sales support but also ensures timely maintenance and parts availability, which can extend the machine’s lifespan and maintain efficient operation over the long term.

Lollipop Machine for Sale: How to Purchase from Gondor Machinery?

To purchase a lollipop candy machine, you need to carefully follow steps like model selection, consultation with sales, arranging payment and logistics, and ensuring post-purchase support. What’s more, by partnering with a trusted food processing machinery manufacturer and clearly communicating your needs, candy factories can secure the right lollipop making machine for your production goals while ensuring long-term technical assistance. Check below for your reference:

Online Purchase Process for a Lollipop Machine

- Model Selection: Choose the right lollipop candy machine based on your production needs (capacity, specifications, budget). Browse our website or platforms for details.

- Consult with Sales: Contact the customer service or sales team to obtain detailed information about the lollipop machine, including pricing, delivery time, and other specifications.

- Place an Order: Confirm the model, configuration, and terms of lollipop making machines, then submit the order. Then we will arrange production and delivery.

- Payment: Choose a suitable payment method and pay the deposit or full amount for the lollipop candy making machines and other food processing machinery.

Pre-Sales Consultation Services

Before purchasing a lollipop making machine, we usually provide the following pre-sales services:

- Technical Consultation: Our project team will recommend the most suitable lollipop candy machine model and configuration based on our customer’s specific production needs, such as production scale, output, product shape, and packaging requirements.

- Customized Solutions: If there are special requirements for global customers, we also offer custom lollipop making machine designs.

- Quotation and Contract: After determining the lollipop candy making machine model, we will provide a detailed quotation and sign a purchase contract with our customers.

Supported Logistics Services:

- Domestic Shipping: We typically use logistics companies to transport lollipop candy machines and other food processing equipment to the specified address. And the cost and delivery time are agreed upon in the contract.

- International Shipping: For overseas customers, we also arrange sea or air transportation for food processing and packaging machinery and assist with export customs clearance, while the customer is responsible for handling import customs clearance.

Post-Purchase Installation, Commissioning, and Technical Support

After purchasing a lollipop making machine, we generally provide the following after-sales services:

- Installation and Commissioning: Gondor machinery can offer online installation guidance to our global customers to install and commission the equipment, which can ensure that it operates correctly.

- Training Services: Technicians from our company can help train our customer’s operators on how to operate and maintain the lollipop making machine on a daily basis.

- Technical Support: We also provide phone, video, or on-site technical support to help customers resolve production issues after they purchase lollipop candy machines from our factory.

Maximize Efficiency with a High-Quality Lollipop Candy Making Machine

Investing in the right lollipop making machine can significantly improve your manufacturing efficiency and product consistency. With advanced candy making machines, you can meet market demand, streamline operations, and produce high-quality products with ease, which can ensure the smooth production processes and achieve the consistent output.

If you’re also looking for the molded lollipop production line, Gondor machinery is here to help. Our team of experts can guide you in selecting the ideal production line for your needs. Contact Gondor Machinery today for a customized lollipop candy machine quote and discover how our cutting-edge lollipop machines can elevate your business. Don’t wait – boost your production capabilities now!