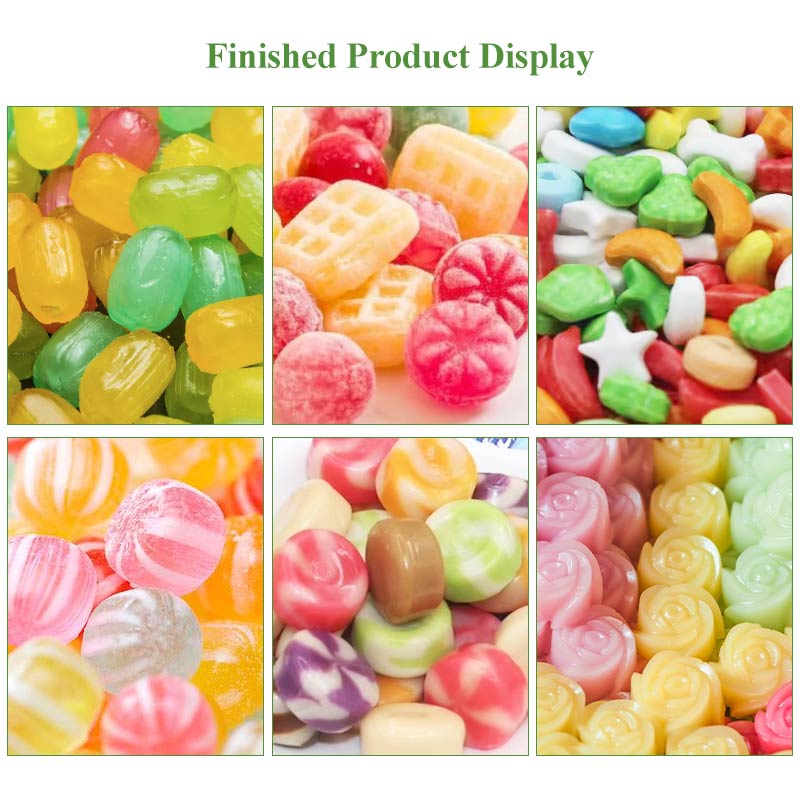

Gondor Molded Lollipop Production Line

A molded lollipop production line is a highly automated, continuously operating food processing system specifically designed for the large-scale production of lollipops with uniform shape, hard texture, and smooth surface. The core process of this production line is “molding,” which involves heating and melting solid sugar into a syrup, which is then injected into specific mold holes using a metering system.

Each mold hole in the production line has a slot for inserting the lollipop stick. After the syrup cools and solidifies within the mold, it forms a candy body that perfectly matches the shape of the mold and is firmly bonded to the stick.

The lollipop molding production line is easy to operate, highly automated, reduces manual intervention, and improves production efficiency and consistency. Furthermore, it can be customized to meet the production needs of different scales and varieties. It is a reliable choice for lollipop production.

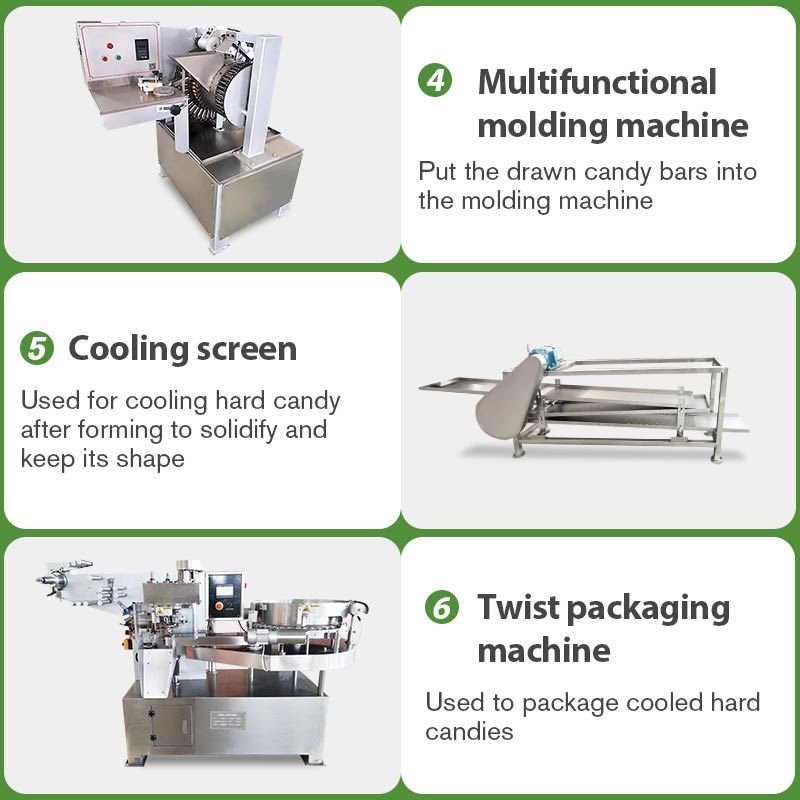

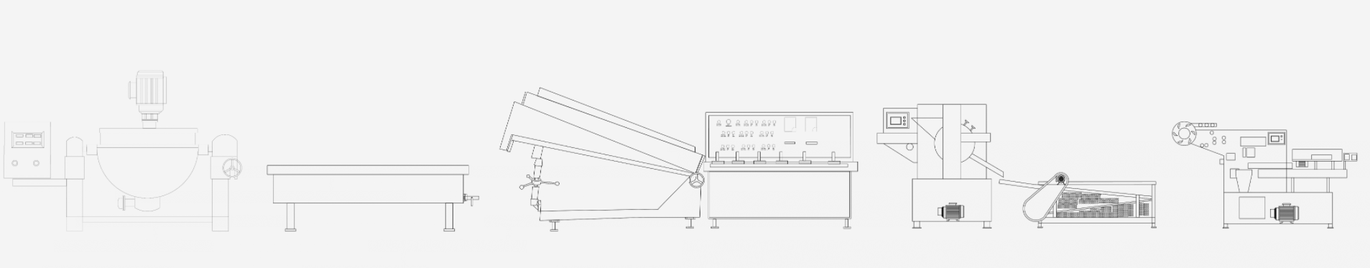

Composition of a Molded Lollipop Production Line

A common molding lollipop production line consists of six types of machines: a sugar cooking pot, a cooling table, a rolling machine, a stretching machine, a forming machine, a cooling screen, and a twisting and packaging machine.

The sugar cooking pot is used to cook the raw materials into syrup.

✅ 1. Sugar Cooking Pot

The sugar cooking pot is used to dissolve and concentrate sugar, syrup, and additives. It heats the raw materials to the temperature and concentration required for lollipop making through precise temperature control. The equipment is usually equipped with temperature sensors, steam or electric heating systems, and stirring devices to effectively prevent scorching, ensure uniform cooking, and improve the taste and clarity of the syrup. The pot body is made of food-grade stainless steel, providing excellent hygiene and corrosion resistance. This equipment is the foundation of lollipop production, providing a stable and high-quality syrup for subsequent molding.

✅ 2. Cooling Table

The cooling table is used to cool the syrup to achieve a suitable temperature and viscosity for molding. In a molded lollipop production line, a cooling table is used to rapidly cool the hot syrup poured from the boiling pot, bringing it to a suitable processing temperature. Its flat stainless steel surface has good thermal conductivity, facilitating operation and cleaning. During cooling, operators can fold and turn the syrup to ensure it cools evenly to a viscosity suitable for the rolling and stretching process. Some machines have adjustable cooling systems to ensure consistent product hardness and improve subsequent molding stability, making it a crucial piece of equipment connecting the boiling and stretching processes.

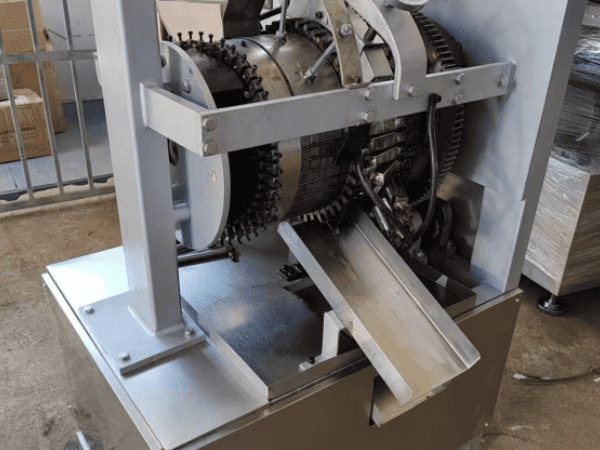

✅ 3. Rolling Bar Machine

A rolling bar machine stretches cooled syrup into long, thin lollipop shapes. The machine uses multi-stage rollers to gradually lengthen and press the cooled syrup into uniform strips, ensuring consistent size and weight during subsequent molding. Adjustable roller speed ensures continuous and stable production. The equipment is constructed of stainless steel, making it sturdy, durable, hygienic, and safe. The automated stretching process reduces human error, increases production efficiency, and ensures the strips meet the appropriate specifications required by the molding machine, making it essential equipment for ensuring consistent lollipop dimensions.

✅ 4. Lollipop Molding/Press Machine:

The forming machine shapes the stretched lollipop syrup into a molding die. It presses the syrup into the lollipop stick by feeding the syrup into a rotating die system. The machine can produce various shapes, such as circles, hearts, animals, and custom patterns, by changing the die. During production, the forming machine ensures uniform shape, smooth surface, and a strong bond between the syrup and the stick. This highly automated, stable, and easy-to-clean machine is a core component determining product appearance and production efficiency.

✅ 5. Cooling Screen: Used to cool the lollipops after molding, allowing them to solidify and maintain their shape.

Cooling screens provide a low-temperature, low-humidity environment, accelerating cooling and solidification after molding, preventing deformation and stick loosening. They typically feature a multi-layer tray system to ensure uniform airflow and consistent cooling for all products. Stable temperature and humidity control helps maintain product shine and prevents moisture absorption. The cabinet features an insulated structure and stainless steel construction, ensuring hygiene, safety, and excellent heat retention. Efficient cooling enhances production speed and finished product stability, a crucial step before packaging.

✅ 6. Twist Packaging Machine

The twist-wrapping machine automatically wraps lollipops and twists the ends for a tight, aesthetically pleasing finish. Featuring high-speed operation, stable sealing, and a uniform appearance, this machine is compatible with various film materials and candy shapes. The packaging process reduces manual contact, improves hygiene and safety, and protects the finished product from moisture, dust, and contamination. Automated packaging not only improves transport convenience but also enhances shelf display and helps extend product shelf life. As the final step in production, it ensures high-quality commercial packaging.