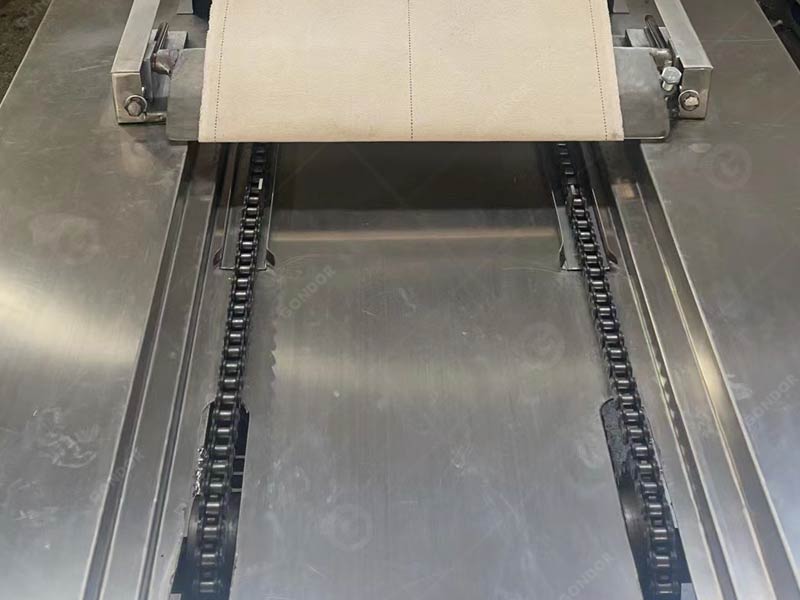

Biscuit Rotary Moulding Machine

The rotary moulding biscuit molder machine integrates multiple functions and can efficiently complete the entire production process from dough rolling and printing to biscuit forming and demolding. Moreover, the machine can make biscuits of different shapes and weights to ensure the stable quality of Taosu biscuits. In addition, biscuit molds of different sizes and shapes can also be customized. The characteristic of biscuit making machine is that it has a high degree of automation, which greatly improves production efficiency and reduces labor costs.

Rotary Moulding Biscuit Molder Machine Specification

| Modle | GD-400 | GD-600 | GD-800 | GD-1000 | GD-BG400 |

| Yield | 100-200 kg/h | 250-300kg/h | 500-600kg/h | 800-1000kg/h | 50-180kg/h |

| Power | 1.5kw | 2.2Kw | 4.5kw | 5.5kw | 2.2kw |

| Voltage | 380-220v /50Hz | 380-220v /50Hz | 380-220v /50Hz | 380-220v /50Hz | 380v/50hz |

| Baking tray size | 400*600mm | 600*600mm | 800*600mm | 1000*600mm | 400*600mm |

| Equipment size | 2350*850*1350 | 2350*1050*1350 | 2500*1350*1350 | 2500*1550*1600 | 2900*850*1350 |

| Weight | 500kg | 850kg | 1300kg | 1500kg | 580kg |

Various Application Markets of Gondor Rotary Moulding Biscuits

Food Processing Plants

Mass production of peach biscuits, supplying them to supermarkets, convenience stores and other sales channels.

Bakery Chains

Used to make homemade peach biscuits in the store to ensure the freshness and uniqueness of the products and attract customers.

E-commerce Platforms

Some entrepreneurs sell homemade peach biscuits through e-commerce platforms, and peach biscuit machines are key equipment for their production.

Central Kitchens

Provide standardized peach biscuit products for multiple catering stores.

Hotels and Restaurants

Serve biscuits as dim sum or dessert to guests.

Export Companies

Produce peach biscuits for export to other countries and regions.

Performance Characteristics of Gondor Biscuit Molder

The biscuit molder integrates efficient automation, flexible customization capabilities and low maintenance characteristics, suitable for large-scale commercial production.

Gondor Biscuit Molding Machine – A Good Partner for Biscuit Production

Gondor rotary moulding biscuit molder machine, extraordinary quality! It is energy efficient, easy to operate, and can accurately shape. Whether it is a small workshop or a large factory, it is your ideal choice. Trust Gondor and use this machine to open the road to selling delicious biscuits for you!