Recently, we successfully partnered with an intermediary client from Afghanistan, providing a 300-500kg sausage production line solution that demonstrated our strengths in efficiency, product quality, and exceptional customer service. As a professional and reliable food processing machinery manufacturer, Gondor machinery thoroughly assessed the client’s needs and understood the market environment. Then, we helped our customers swiftly finalize their purchase of the sausage processing line and other meat processing machinery. In the near future, our client will experience the stability and performance of our meat processing equipment, along with our excellent support.

Gondor Sausage Production Line in Afghanistan

What’s more, they have expressed their desire for continued collaboration with Gondor Machinery. If you are looking for reliable food processing equipment, Gondor Machinery is here to provide customized solutions tailored to your business. Check below for the project details!

Project Overview: Sausage Production Line in Afghanistan

In July 2024, Gondor Machinery received an inquiry from an intermediary client in Afghanistan via our official website, who sought a sausage production line capable of producing 300-500kg per hour. As for this client from Afghanistan, he had a strong understanding of both machine performance and market pricing. What’s more, their goal was to find a solution that would not only meet their production needs but also deliver long-term value. Ultimately, after careful comparison and analysis, they chose the Sausage Production Line, Vacuum Packaging Machine, and Poultry Cutting Machine from our company.

In the competitive global food processing machinery market, customers face two main challenges: finding high-quality equipment and partnering with a supplier that offers reliable service and long-term cooperation. Gondor Machinery is committed to addressing these needs by offering comprehensive solutions tailored to the food processing industry, from equipment selection to customized production lines, along with excellent after-sales support.

Afghan Client Communication and Project Progress

- We received the inquiry on July 20, 2024. Over the next 23 days, we engaged in multiple discussions with the client to understand their specific requirements. As an intermediary, the client had compared the automatic sausage production line quotes from several suppliers and was highly sensitive to pricing. Initially, our pricing seemed higher compared to other competitors. However, through detailed explanations and demonstrations of the superior performance and quality of our sausage production line, they gradually recognized the value our company can offer.

- In addition, during these discussions, we shared comprehensive product specifications, real case studies, and photos of machines in operation, which can build confidence in our reliability and product quality. Meanwhile, we highlighted our long-term partnership potential and after-sales support, which further strengthened the client’s trust in Gondor Machinery, a reliable manufacturer and supplier in the food processing industry.

Sausage Production Line Solution: High-Quality Equipment with Flexibility

Gondor Machinery ultimately provided a tailored solution to meet the client’s specific production needs, which can ensure the high performance and long-term reliability with our clients.

-

Product Advantages and Quality:

Durability and Stability: The sausage production line for our Afghan customers is designed for heavy-duty use, which aims to maintaining the stability during extended operations with minimal downtime and maintenance needs.

Hygiene and Safety: The sausage production line and other meat processing machinery are built in accordance with international food safety standards, which feature easy-to-clean designs that prevent cross-contamination and ensure product quality.

High-Efficiency Production: What’s more, the sausage production line meets the daily output requirements of our Afghan clients, which can ensure the fast, efficient sausage production for their customers. -

Customization and Flexibility:

The customized sausage production line was tailored to the client’s specific production capacity of 300-500kg per hour. Additionally, the system is flexible enough to accommodate future expansion and upgrades as the client’s business grows.

-

Pricing and Value for Money:

Although the Afghan client initially felt the pricing was on the higher side, after two weeks of in-depth discussions, we adjusted factors such as delivery times, spare parts, and shipping costs. In the end, our project manager and our clients finally arrived at a mutually satisfactory pricing arrangement. What’s more, we emphasized the machine’s long-term operational efficiency and low maintenance costs, which demonstrate that our meat processing equipment offers excellent value over its lifecycle.

After-Sales Service and Technical Support

In addition to providing top-quality food processing machinery, our company is also known for our comprehensive after-sales service and technical support, which can ensure the smooth operation and peace of mind for our clients.

- Technical Support: From installation to commissioning and training, we provided full support to help our global client quickly get their production line up and running. Additionally, our technical team is also available to assist with any issues that may arise during production, which aims to ensure the production line operates smoothly.

- Spare Parts and Service: We guarantee the fast and reasonably priced spare parts to prevent any production delays due to equipment downtime. Moreover, our responsive after-sales service can reduce machine downtime, which can ensure the sausage production line continues to run efficiently and reliably.

Project Outcome and Client Feedback

- After 23 days of communication and negotiations, the client officially placed their order on August 12, 2024. With an efficient 20-day production cycle, we successfully completed the shipment of the sausage production line and other machinery on schedule by September 6, 2024, which can meet the September 6 shipping deadline.

- During the whole process, the Afghan client was impressed with our ability to meet the delivery schedule, as well as the quality of the equipment and the support we provided. They expressed strong satisfaction with the project and indicated their intent to pursue further collaborations with Gondor machinery in the future.

Expertise and Industry Experience

Gondor machinery has extensive experience in the food processing machinery industry, making us a trusted partner for clients worldwide. Our knowledge of different markets and production needs allows us to provide tailored solutions that meet the highest international standards.

- Industry Expertise: With years of experience, we understand the diverse demands of the food processing industry and offer custom solutions that drive efficiency and productivity.

- Reputation and Customer Satisfaction: Gondor machinery enjoys a strong reputation in the global market, and we consistently receive the positive feedback for our high-quality food processing equipment and top-tier service. Our dedication to excellence has solidified our standing as a leading brand in the food processing machinery sector.

Product Details of Sausage Production Line in Afghanistan

This sausage production line is specifically designed for the Afghan customer, and covers the entire process from frozen meat handling to final packaging. It greatly improves production efficiency and quality, which can meet large-scale production needs. At the same time, each machine is focused on efficiency, durability, and ease of use, which can ensure the smooth production at every stage, reduce the manual operation complexity, and enhance the product consistency. With this automatic sausage production line, the Afghan customer can increase production capacity and improve product hygiene and competitiveness. Check the related machines below:

GD-100 Frozen Meat Grinder

The frozen meat grinder is designed to grind frozen or semi-frozen meat blocks directly, which can eliminate the need for defrosting, and saves time and energy. Equipped with a powerful 5.5kw motor, this machine ensures fast and efficient grinding. With a production capacity of 500kg/h, this frozen meat grinder is ideal for small to medium-sized food processing businesses.

Application & Advantages:

This meat grinder is suitable for pre-processing raw materials for sausages, meatballs, and other meat products. And the primary advantage is that it grinds meat without thawing, which can preserve the freshness of the meat and reduce the risk of bacterial growth. Moreover, the sturdy design ensures stability over long-term use and makes it easy to clean.

GD-100 Frozen Meat Grinder in Afghanistan

- Model: GD-100

- Capacity: 500kg/h

- Power: 5.5kw

- Voltage: 380v/50hz 3phase

- Size: 900*580*960mm

- Weight: 240kg

GD-80 Meat Bowl Cutter

The meat bowl cutter features a high-efficiency 14kw power system, which can finely chop meat, vegetables, and other ingredients into a smooth paste in a short time. And the machine is equipped with high-speed rotating blades and a stainless steel structure, which can ensure a uniform and hygienic chopping process.

Application & Advantages:

This meat bowl cutter machine is ideal for processing sausages, meatballs, fish balls, and similar food products. Furthermore, the efficient and uniform chopping effect ensures a fine texture in the final product. Besides, operators can flexibly adjust the texture and mouthfeel of the products by controlling the blade speed and time, which can cater to different market demands.

Buy GD-80 Meat Bowl Cutter in Afghanistan

- Model: GD-80

- Power: 14kw

- Voltage: 380v/50hz 3phase

- Size: 1800*1100*1240mm

- Weight: 800kg

GD-150 Sausage Meat Mixer Machine

The sausage meat mixer machine is designed for food processing with a 150kg mixing capacity. Each batch can quickly and uniformly blend various ingredients.what’s more, the meat mixer is simple to operate, consumes low power, and is an ideal choice for small and medium-sized food processing businesses.

Application & Advantages:

The sausage meat mixer machine is widely used for mixing fillings for sausages, dumplings, and meatballs. And its main advantage lies in its efficient and uniform mixing, which can ensure the thorough integration of seasoning and meat, resulting in a more consistent taste.

GD-150 Sausage Meat Mixer Machine in Afghanistan

- Model: GD-150

- Capacity: 150kg/batch

- Power: 2.2kw

- Voltage: 380v/50hz 3phase

- Size: 1470*520*910mm

- Weight: 250kg

Pneumatic Sausage Filling Machine

The pneumatic sausage filler, with a 1.5kw motor, can fill 300-500kg of sausages per hour, which is equipped with a 60L hopper and pneumatic operation. And it can ensure each sausage is filled evenly and tightly.

Application & Advantages:

This sausage filling machine is suitable for producing various sausages and is highly efficient and stable in mass production. What’s more, the pneumatic operation reduces manual labor, and the compact design takes up minimal floor space.

Gondor Pneumatic Sausage Filling Machine

- Capacity: 300-500kg/h

- Power: 1.5kw

- Hopper Capacity: 60L

- Voltage: 380v

- Size: 1040*620*1440mm

- Weight: 150kg

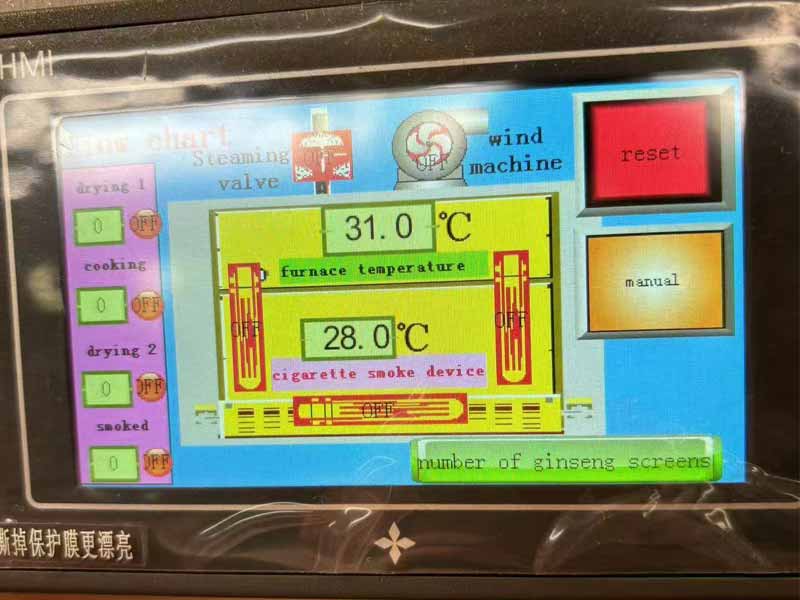

GD-250 Commercial Smoker Oven:

The commercial smoker oven, equipped with a steam generator, can process up to 250kg of meat products per batch. Its design includes heating and steam functions, which impart a unique smoky flavor while ensuring the sterilization and product maturation.

Application & Advantages:

This commercial smokehouse is ideal for processing sausages, ham, bacon, and other meat products. With a high level of automation, it is easy to operate and can handle large batches, which can increase the production efficiency.

GD-250 Commercial Smoker Oven

- Model: GD-250

- Capacity: 250kg/batch

- Power: 3kw

- Heating Power: 24kw

- Voltage: 380v/50hz 3phase

- Size: 2300*1350*2600mm

- Weight: 800kg

GD-600/2s Vacuum Packaging Machine

The GD-VAPM dual-chamber vacuum packaging machine provides an efficient vacuum sealing solution. It can handle four products simultaneously in each batch, which can ensure a tight vacuum seal during packaging.

Application & Advantages:

This packaging machine is suitable for packaging a variety of meat products and sausages. Vacuum packaging extends the shelf life of products and helps maintain freshness during transport and storage.

Buy GD-600/2s Vacuum Packaging Machine

- Model: GD-600/2s

- Power: 3kw

- Voltage: 380V

- Size: 1450*650*980mm

- Sealing Length: 60cm*4pcs

- Weight: 260kg

GD-600 Chicken and Duck Cutting Machine

The chicken and duck cutting machine can efficiently cut 600-750 pieces per hour with precision. It cuts meat in a single pass and offers adjustable cutting lengths and widths, which can meet various product specifications.

Application & Advantages:

This meat cutting machine is widely used for cutting chicken, duck, and other poultry meat, especially in large kitchens and processing plants. The adjustable cutting size makes it adaptable to different production requirements.

GD-600 Chicken and Duck Cutting Machine

- Model: GD-600

- Capacity: 600-750pcs/h

- Voltage: 380v 50hz

- Cutting Length: 10-60mm

- Cutting Width: 290mm

- Size: 1300*600*950mm

- Weight: 230kg

Gondor Machinery: Your Partner for Efficient Food Production

Our successful partnership with the Afghan client is a testament to our ability to meet the challenges of price-sensitive markets while delivering reliable, high-performance machinery and exceptional service. We helped them achieve fast, efficient sausage production while ensuring long-term stability and reliability for future growth. Whether you need customized production lines, installation support, or ongoing technical assistance, we are dedicated to putting your needs first. What’s more, we offer top-quality, efficient food processing machinery designed to help your business succeed. Get in touch with Gondor machinery today to explore how we can help your production line achieve new levels of efficiency and success!