Chocolate manufacturing technology is constantly improving. From raw material processing to product molding, each link relies on advanced equipment support. This article will focus on key technologies such as chocolate manufacturing, cacao beans processing, and chocolate moulding equipment to help customers better understand the core equipment in the chocolate production process and provide the latest equipment solutions.

Chocolate Manufacturing: From Raw Materials to Delicious Art

Chocolate production involves multiple key links, and each link requires precise equipment support. Here are the main steps:

These links and equipment together ensure the high quality and consistency of chocolate.

Cacao Beans Processing: The Basis of Chocolate

The quality of chocolate is closely related to high-quality cocoa beans, and the processing of cocoa beans is the first step in chocolate manufacturing. The following are the key processing links and equipment:

Chocolate Moulding Equipment: The Key to Molding and Packaging

The appearance and packaging of chocolate directly affect the market appeal, so chocolate moulding equipment is crucial. These devices ensure consistent chocolate molding and stable quality through high-precision design. The chocolate mold forming machines on the market are mainly divided into two categories: liquid chocolate molding machines are used to produce chocolates of different shapes, while solid chocolate molding machines are suitable for large-scale standardized production. With the increase in personalized needs, customized molds and automated equipment have gradually become a market trend.

Future Trends: Automation and Intelligent Equipment Leading the Way

With the advancement of science and technology, the chocolate manufacturing industry is moving towards a more efficient and intelligent direction. Automation equipment and robotics technology have improved production efficiency and quality. Automated production lines can automate the feeding, mixing, refining, molding, and packaging of raw materials, reducing human errors and costs. For example, intelligent packaging equipment can automatically adjust the packaging method according to the product, while high-precision temperature control systems and intelligent detection equipment monitor production parameters in real-time to ensure the best quality of each batch of chocolate.

Comprehensive Solutions from Raw Materials to Packaging

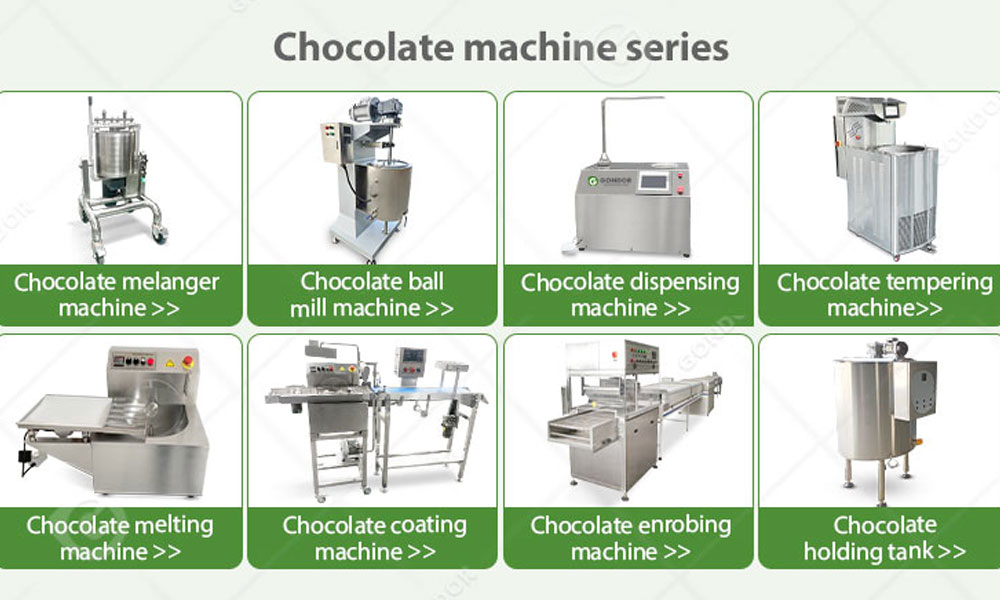

The following are the relevant equipment in the chocolate production process, covering a comprehensive solution from raw materials to packaging:

Used to wash, crush, shell, and other processing cocoa beans.

Used to evenly mix raw materials and grind particles to ensure the taste of chocolate.

Used to mold chocolate liquid into various shapes.

Ensure that chocolate can be evenly cooled after molding to maintain quality.

Used for automated packaging of chocolate products.

Used to coat the surface of chocolate to provide additional flavor and beauty.

In addition, we also provide customized equipment solutions. According to different chocolate categories and production scales, we recommend the most suitable equipment combination for customers to ensure an efficient and smooth production process.