Jelly candy is loved by consumers for its rich colors and chewy taste. Nowadays, with the rapid growth of the jellied candy market, many food manufacturers hope to achieve mass production in an efficient and precise way. This article will introduce a multifunctional jelly depositor machine, which provides a convenient, fast and high-quality solution for jellied candy production through an integrated automatic operation process. The following is a detailed usage and production process.

Jelly Depositor Machine’s Multifunctional Advantages

This soft candy forming machine integrates heating, packaging, forming and demoulding functions, from raw material mixing to finished soft candy production in one step. Whether it is fruity soft candy, nutritious jelly soft candy, or personalized soft candy with rich shapes, this equipment can meet different needs, making production efficient and burden-free.

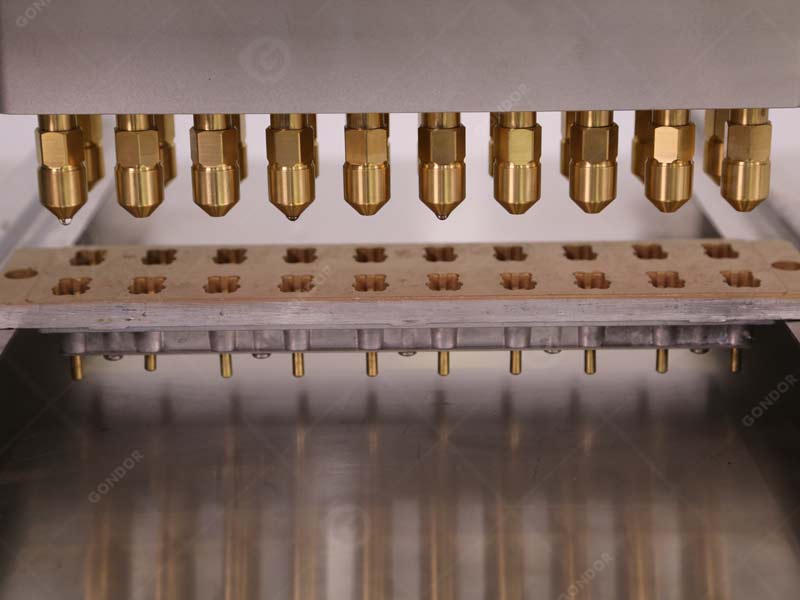

The packaging system of the equipment adopts precision technology to ensure that the size and weight of each soft candy are consistent, reducing raw material waste.

The whole machine process is automated, reducing manual intervention, and suitable for large-scale batch production.

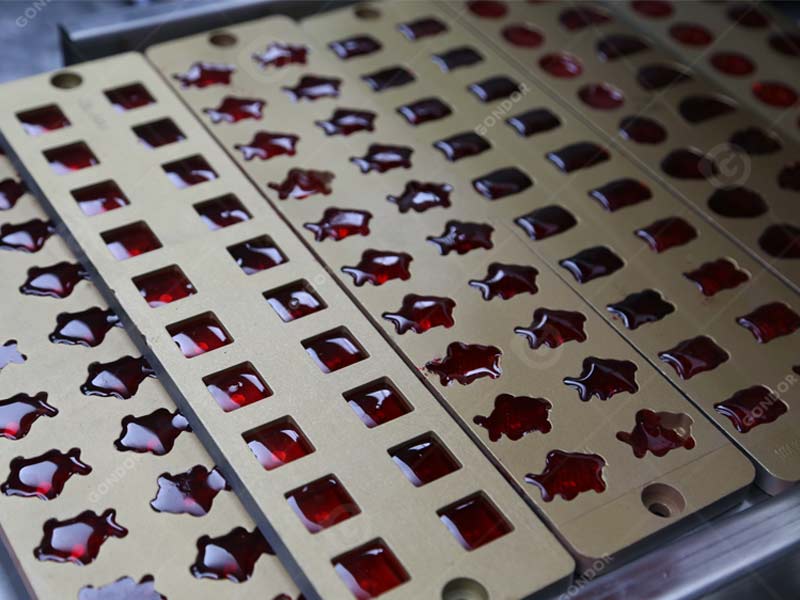

Supports the production of soft candies of various shapes and formulas, and quickly changes molds to meet the needs of diversified products.

The modular structure is easy to disassemble and clean, ensuring the hygiene and safety of the production process.

User Guide: How to Make Perfect Gummy Candies with Mogul Gummy Machine

Material Preparation

- Pectin, Fruit Pulp, or Ggelatin: Provides the main texture of gummy candies.

- Sugar: Provides sweetness to gummy candies.

- Water: Helps gummy candies form the right colloid.

- Coloring and Flavoring (optional): Gives gummy candies rich colors and flavors.

Mogul Starch Molding Machine Operating Steps

Application Expansion: Unlimited Possibilities for Enriching Product Lines

With this multifunctional jelly depositor machine, you can easily produce various types of soft candy products, such as:

Improve Your Production Process: Use with Other Equipment

Use equipment such as cooling tunnels, candy panning machines or vertical form fill seal machines to improve production efficiency and increase product diversity. Cooling tunnels accelerate the formation of soft candies, sugar coating machines add outer flavor, and packaging machines simplify subsequent processing processes, helping your soft candy production line to easily meet market demand.

Gondor Candy Coating Machine

Gondor Vertical Packing Machine

Gondor Vertical Packaging Machine with Ten Head Weigher

For more information on the application details of this versatile soft candy forming machine, please contact us. We will provide you with professional equipment recommendations to help you achieve efficient and accurate soft candy production!