In the global chocolate production industry, chocolate moulding machine and chocolate melting tempering machine are vital equipment. Whether it is a small workshop or large-scale industrial production, these machines can help produce high-quality chocolate products. This FAQ will answer some common questions about these machines and help you choose the chocolate processing equipment that best suits your needs.

What Is a Chocolate Moulding Machine? How Does It Work?

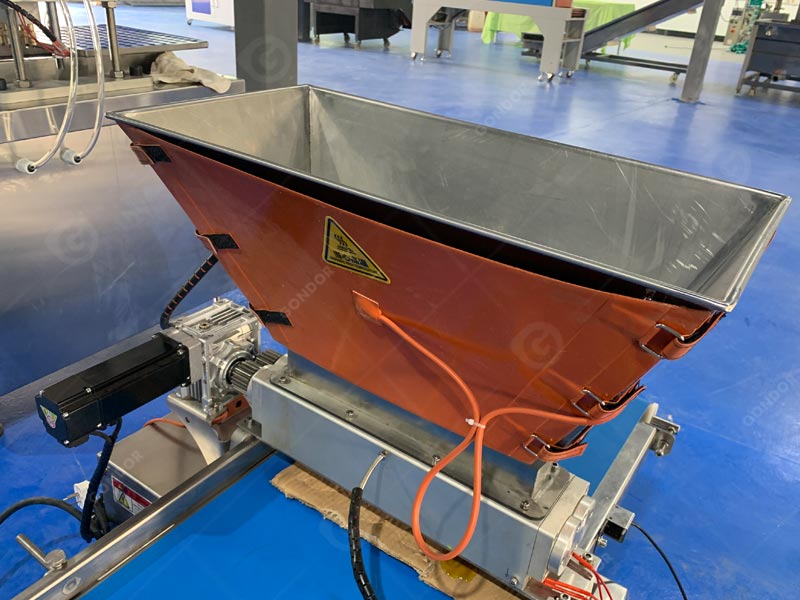

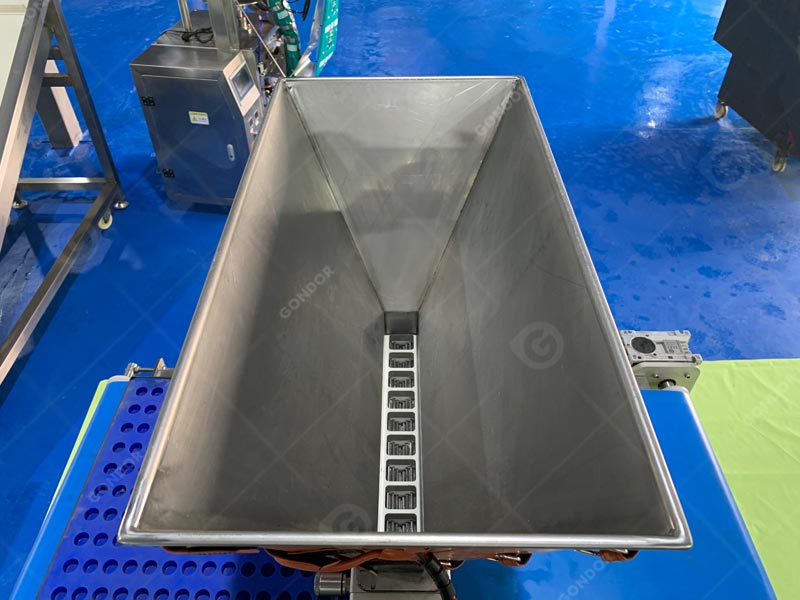

A chocolate molding machine is a device specially used for producing candies, chocolate candies, and other similar products. These machines inject molten chocolate or candy liquid into pre-designed molds and then cool and harden to obtain molded chocolate candies.

- The machine first injects chocolate or candy liquid into the mold.

- Then, the machine cools the mold in the cooling system for a while to make the liquid-solid.

- Finally, the molded candy is taken out of the mold to complete the production of the product.

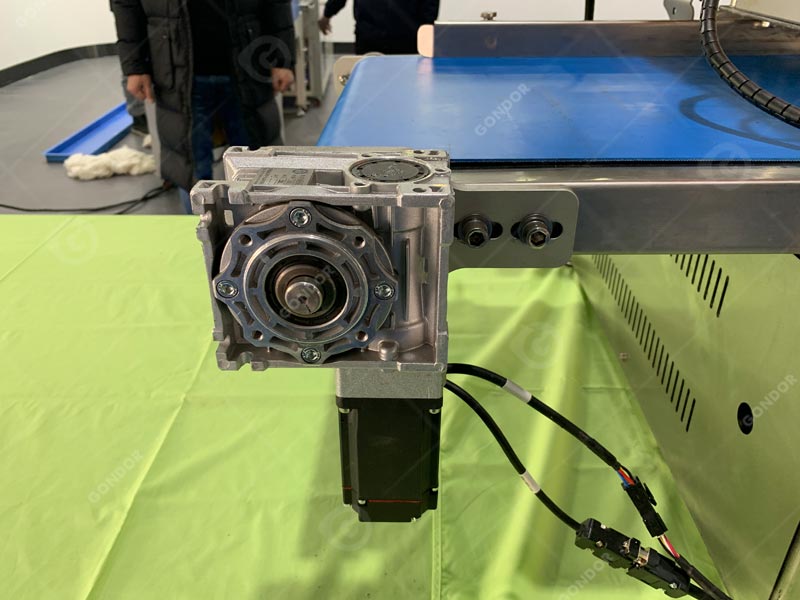

- The high degree of automation, reducing manual operation.

- It can produce chocolate candies in various shapes and flavors with great flexibility.

What Is the Importance of Chocolate Melting Tempering Machine?

The chocolate melting and tempering machine is an indispensable piece of equipment in the chocolate processing process. Its main function is to heat the solid chocolate to a melting state and ensure the quality and taste of the chocolate reaches the best level through the tempering process.

- By accurately controlling the temperature, the machine gradually heats the chocolate to the right melting point.

- The machine then adjusts the temperature of the chocolate according to a specific tempering program to ensure that its crystallization process is well controlled, which is crucial for the gloss, taste, and hardness of the chocolate.

- The tempering process makes the fat of the chocolate crystallize evenly, thus avoiding uneven surfaces and graininess.

- If the chocolate is not tempered, the final product may have a gray hoarfrost, affecting appearance and taste.

- A good tempering process can increase the fluidity of the chocolate and make it more stable during the production process.

What Factors Should Be Considered When Choosing Chocolate Equipment?

When choosing the right chocolate processing equipment, in addition to the type of equipment, you also need to consider the following factors:

How Do These Chocolate Machines Work in Conjunction with Other Related Equipment?

The chocolate production process requires multiple steps, so chocolate equipment often needs to work together. In addition to the above machines, you can also consider the following chocolate equipment:

After the chocolate is poured and formed, it further coats the surface of the product with a thin layer of chocolate.

It is used to accelerate the chocolate molding and cooling process to ensure that the chocolate product solidifies quickly.

It is suitable for coating chocolate on existing candies or biscuits to provide a rich taste experience.

By combining these machines properly, you can efficiently and consistently produce high-quality chocolate products to meet the needs of the global market.

Choose Gondor’s Chocolate Equipment to Improve Production Efficiency

Choosing the right chocolate equipment is crucial to improving production efficiency and product quality. Chocolate moulding machines and chocolate melting tempering machines are the core equipment for chocolate production. By reasonably coordinating other related equipment, you can optimize the production process. If you need more advice or learn more about our products, please contact us and we will provide you with a tailor-made solution.