The global chocolate industry continues to expand, and many companies are investing in efficient and advanced production equipment. The following FAQs will help you understand equipment such as electric cocoa bean grinder, chocolate-making plant, and chocolate depositing machine, and help you choose the right production equipment.

What Is an Electric Cocoa Bean Grinder?

An electric cocoa bean grinder grinds cocoa beans into fine cocoa liquid blocks through high-speed rotating grinding discs, ensuring the taste and texture of chocolate. It is a key equipment in large-scale chocolate production.

FAQ

What Are the Main Equipment in a Chocolate Making Plant?

A chocolate-making plant is a complete chocolate production system, including the whole process from raw material preparation to finished product production. Usually, a chocolate production line includes multiple equipment, such as an electric cocoa bean grinder, cocoa liquor mixer, chocolate tempering machine, chocolate casting machine, etc.

FAQ

How Does a Chocolate Depositing Machine Work?

A chocolate depositing machine is a very important equipment in the chocolate production process, especially in the molding process of chocolate molds. It precisely controls the temperature, flow rate, and pressure to accurately pour the melted chocolate into the mold, thereby making chocolate products of various shapes and specifications.

FAQ

How to Choose Chocolate Equipment?

When choosing chocolate equipment, you need to consider the following factors:

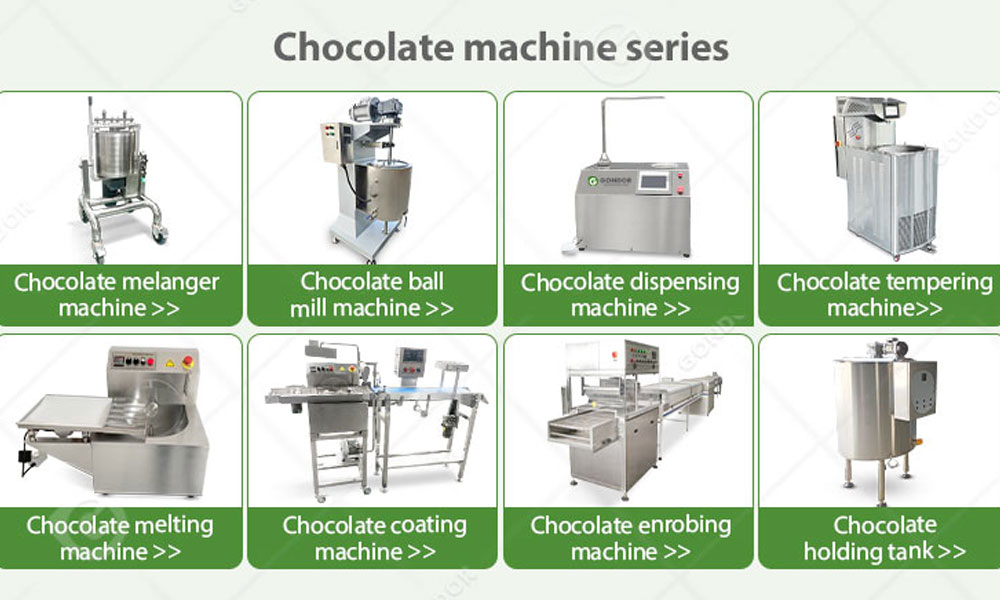

What Other Related Chocolate Production Equipment Are There?

In addition to the electric cocoa bean grinder, chocolate-making plant, and chocolate depositing machine, there are many key equipment in the chocolate production process. For example:

- Chocolate Tempering Machine: Used to adjust the temperature of chocolate to achieve the best crystallization state, thereby ensuring a smooth and shiny surface.

- Chocolate Panning Machine: Used to apply a uniform layer of chocolate coating to candies or other food products, suitable for making chocolate candies.

Get Professional Advice and Solutions

Chocolate production relies on professional equipment to ensure quality and efficiency. From an electric cocoa bean grinder to a chocolate-making plant to a chocolate depositing machine, each piece of equipment is crucial. Understanding its function can help you make an informed purchasing decision. For more information or consultation, please contact Gondor. We provide professional advice and solutions.