Bienvenue sur notre page FAQ pour les équipements d'emballage de bonbons! Nous sommes spécialisés dans la fourniture d'équipements automatisés efficaces et fiables tels qu'un machine d'emballage de barres chocolatées aux clients du monde entier. Que vous soyez une petite entreprise ou une grande usine, nous pouvons vous fournir des solutions d'emballage qui vous conviennent. Vous trouverez ici des questions et réponses courantes sur ces équipements pour vous aider à mieux comprendre nos produits..

Qu'est-ce qu'une machine d'emballage de barres chocolatées?

Une machine d'emballage de barres chocolatées est un dispositif d'emballage automatisé de type oreiller spécialement conçu pour emballer des bonbons dans des matériaux d'emballage.. La machine est conçue pour emballer efficacement et précisément des barres chocolatées de différentes formes et tailles., garantir la beauté et la fonctionnalité de l’emballage.

Qu'est-ce qu'une machine d'emballage Candy Twist?

Une machine d'emballage Candy Twist est un appareil qui fournit un emballage torsadé pour les bonbons. (comme des bonbons durs, chocolats, boules de bonbons, etc.). En tordant les extrémités du papier d'emballage, la machine peut créer une apparence unique et un effet d'étanchéité pour les bonbons.

Principales caractéristiques

- Conception d'étanchéité torsadée: Les extrémités du papier d'emballage sont torsadées pour garder les bonbons frais et attrayants.

- Grande vitesse: La machine peut emballer un grand nombre de bonbons en peu de temps, adapté à la production de masse.

- Diversité des matériaux d'emballage: Il prend en charge l'utilisation de différents types de papier d'emballage, comme du papier transparent, feuille de métal, etc., pour répondre aux différents besoins du marché.

Qu'est-ce qu'une machine à sceller les bonbons?

Une machine à sceller les bonbons est un appareil utilisé pour sceller les sacs de bonbons. Il garantit que les bonbons restent frais dans le sac et évite toute contamination externe en chauffant ou en comprimant le sac..

Comment choisir la bonne machine d'emballage?

Choisir la bonne machine d'emballage de bonbons nécessite de prendre en compte les facteurs clés suivants:

Les exigences de maintenance et d’entretien de ces équipements sont-elles élevées ??

Afin de garantir que votre équipement d'emballage de bonbons puisse fonctionner efficacement et pendant longtemps, un entretien et un entretien réguliers sont très importants. Voici quelques suggestions d’entretien de base:

Nettoyer les parties actives de la machine, surtout les parties en contact avec les bonbons, pour éviter les résidus de sucre ou de matériaux d'emballage.

Vérifiez régulièrement les pièces clés de la machine, comme les bandes transporteuses, dispositifs d'étanchéité, lames de coupe, etc., pour assurer leur fonctionnement normal.

Ajoutez régulièrement de l'huile lubrifiante aux pièces mécaniques pour réduire la friction et prolonger la durée de vie de l'équipement..

Maintenir la précision de la machine et calibrer régulièrement l'équipement pour garantir la précision de la taille de l'emballage.

Si nécessaire, vous pouvez également choisir de coopérer avec nous. Nous fournissons des services de maintenance des équipements et de support technique pour aider votre ligne de production à rester dans les meilleures conditions.

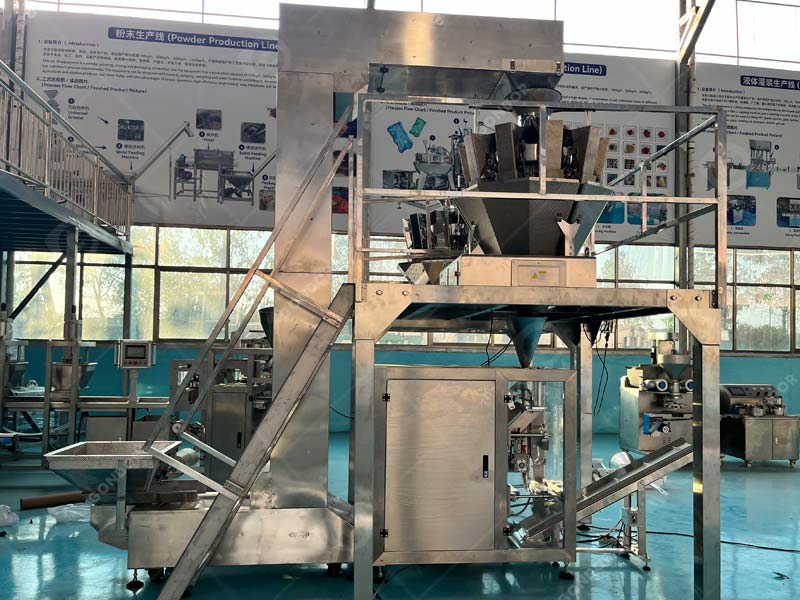

Recommandation d'équipement connexe

En plus des machines d'emballage de bonbons, nous fournissons également une variété d’autres équipements connexes pour optimiser votre processus de production:

- Machine de tunnel thermorétractable: Enveloppez étroitement le produit avec un film rétractable chauffé pour assurer la protection et l'étanchéité..

- Machine à compter: Comptez et distribuez avec précision les bonbons pour garantir une quantité constante dans chaque paquet..

Machine de tunnel thermorétractable

Machine à compter

Obtenez plus d'informations ou demandez un devis

Si vous êtes intéressé par nos machines d'emballage de bonbons ou si vous souhaitez en savoir plus sur équipement d'emballage, n'hésitez pas à contacter notre équipe de vente professionnelle. Nous vous fournirons des solutions personnalisées en fonction de vos besoins pour vous aider à améliorer l'efficacité de la production et à réduire les coûts..

Merci pour votre visite. Si vous avez des questions, n'hésitez pas à nous contacter!