When it comes to producing fluffy, consistent, and high-quality marshmallows at scale, it is fairly crucial to understand both the marshmallow make process and the equipment behind it. At Gondor Machinery, we specialize in designing and manufacturing advanced food processing machinery which is tailored for marshmallow production, from small-scale craft operations to fully automated industrial lines. Therefore, we will explore marshmallow how to make, the step-by-step production process, and how modern machinery enhances both efficiency and product quality.

What Are Marshmallows Made Of?

Before diving into the full process of marshmallow how is it made, it is important to understand the basic ingredients, and these ingredients combine to form the soft, airy confectionery that is popular around the world.

Ingredient Mixing

Provides sweetness and structure. Glucose syrup helps prevent crystallization and ensures a smooth, elastic texture, which is essential for mass production.

Water

Acts as a solvent to dissolve sugar and gelatin. The water content influences the final moisture level and softness of the marshmallow.

Gelatin

The key gelling agent that gives marshmallows their chewy, springy consistency. It stabilizes the aerated foam structure.

Air

Introduced during the whipping process, air gives marshmallows their light, fluffy volume. Uniform aeration is critical for texture and shape.

Flavoring agents such as vanilla

Adds distinctive taste. Vanilla is most common, but fruit, coffee, or custom flavors are used depending on the product line.

Optional ingredients

Cornstarch prevents sticking and helps during molding. Food coloring is used to enhance appearance and differentiate products.

Marshmallows: How to Make Them at Scale

Industrial marshmallow production requires more than just the right ingredients. It demands precision, consistency, and reliable automation at every stage. From ingredient preparation to final shaping and packaging, each step must be optimized for speed, hygiene, and uniformity. Gondor Machinery delivers complete marshmallow production lines tailored for efficient, high-output operations.

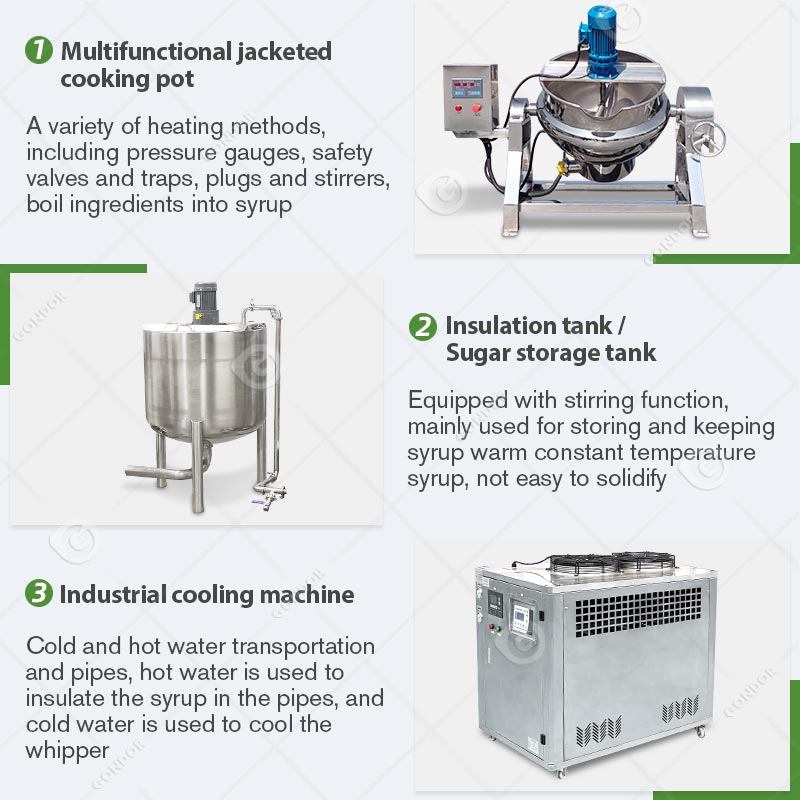

Ingredient Mixing

Production starts by heating sugar, glucose syrup, and water to a specific temperature to form a stable sugar solution. This step is critical to achieving the right texture. Gondor Machinery provides automatic cooking systems with precise temperature control, ensuring consistent quality in every batch.

Aeration and Gelatin Addition

Gelatin is dissolved and blended into the syrup. The mixture is then whipped to incorporate air, which gives marshmallows their signature lightness and volume. Our high-speed aeration mixers are engineered to introduce fine, uniform air bubbles, maximizing product softness and structure.

Flavoring and Coloring

At this stage, flavor extracts and coloring agents are added, depending on the desired final product. Our precision dosing units accurately introduce these ingredients, maintaining taste and visual consistency across batches.

Extrusion or Depositing

The whipped mixture is then formed by extrusion or depositing into specific shapes and sizes. Gondor’s extruders and depositors support continuous, high-capacity production, customizable for ropes, cubes, or molded shapes.

Cooling and Starch Handling

If a starch molding process is used, the marshmallows are allowed to set and cool before being demolded. Excess starch is then removed or recycled. Gondor offers cooling tunnels and starch removal systems designed for maximum efficiency and hygiene.

The Role of Machinery in Marshmallow Production

Understanding marshmallow how is it made also involves recognizing the essential role of equipment. Consistency, food safety, and production scalability depend on machinery that is:

- Automated and programmable for precise control

- Built with stainless steel for food-grade standards

- Equipped with CIP (Clean-In-Place) systems

- Modular and easy to expand or maintain

Choosing Gondor Machinery for Your Marshmallow Production Needs

Whether you are researching marshmallow how to make for a new production line or upgrading existing facilities, Gondor Machinery offers:

- Custom-designed production lines based on output capacity

- Comprehensive project support, including layout planning and on-site installation

- Long-term technical support and spare parts supply

- CE-certified, energy-efficient equipment

- User-friendly interface systems with automated control

Building a Scalable and Efficient Marshmallow Production Line

The marshmallow make process has advanced from small-batch handcrafting to high-speed industrial production. With the right equipment and technical support, manufacturers can produce consistent, high-quality marshmallows while maximizing efficiency and minimizing waste. Gondor Machinery is a trusted global partner in the food processing machinery. Contact our team today to discuss customized machinery solutions for your marshmallow production needs, whether you are just learning marshmallows how to make or looking to scale up a full production line.