Candy-making is a creative and technical job, especially when it comes to mass production. Today, we will introduce how to make perfect gummy candies with a gummy mold machine and how to package these delicious candies with the help of a gummy candy packaging machine, providing you with a one-stop solution from making to packaging.

Candy Depositors: The Core of Efficient Candy Production

Candy depositors are the basic equipment for making gummy candies. Through the depositing process, the shape, size and texture of each piece of candy can be precisely controlled, whether it is a classic gummy candy cube or a unique animal shape, it can be easily achieved with a depositor.

Candy depositors usually come with a precise temperature control system to ensure that the syrup is deposited at the ideal temperature for the ideal taste and appearance.

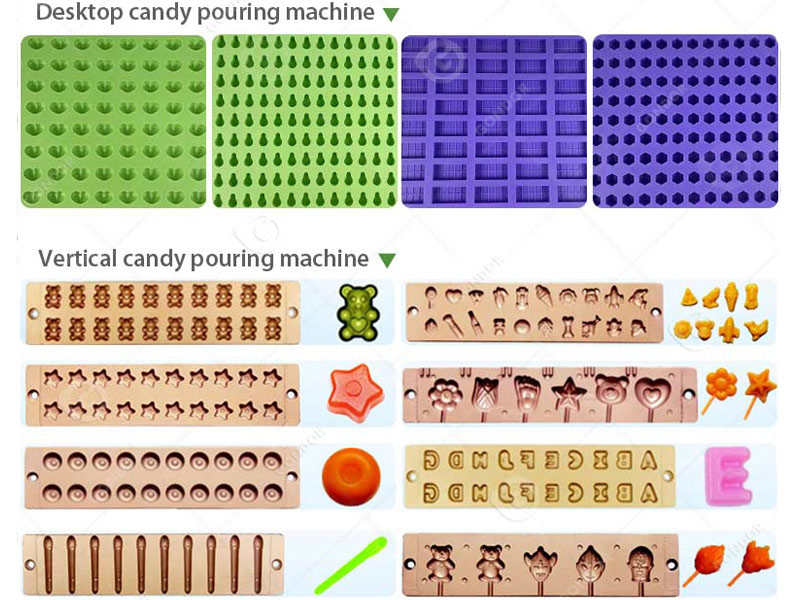

Many depositors support a variety of molds to meet customer needs for different shapes of candies. For example, you can easily switch to a bear-shaped mold to create a cute “gummy bear” for you.

Adding the right amount of juice, flavorings, and pigments to the candy depositing machine can add different flavors and colors to the soft candy, making your candy more attractive.

Gondor Candy Depositor Machine

Gondor Vertical Candy Depositor

Gummy Filling Machine: The Key to Improving Production Efficiency

Gummy filling machines play an indispensable role in the candy-making process. For large-scale production of soft candy, the packaging process is crucial. By using a gummy bear filling machine, the packaging speed can be accelerated while ensuring that each portion of soft candy is packaged intact.

- Automated Packaging: Soft candy packaging machines usually have efficient automation functions, which can automatically complete multiple links such as packaging and sealing, greatly improving production efficiency.

- Adjustable Packaging Speed: The speed of the packaging machine can be adjusted according to the number of candies and production needs, and it is highly flexible.

- Multi-Level Protection: High-quality soft candy packaging machines can support a variety of packaging materials, which can not only maintain the taste of the candy, but also extend the shelf life.

Whether it is traditional soft candy packaging or small packaging with a transparent window, it can be achieved through a soft candy packaging machine, providing you with a beautiful and convenient packaging effect.

Create an Efficient Production Line

In candy production, gummy mold machines, and gummy bear filling machines complement each other to form a complete production process. Here are some matching suggestions:

Gondor Gummy Candy Production Line

Gondor Hard Candy Production Line

Gondor Automatic Marshmallow Production Line

Explore More Candy Manufacturing Solutions

Whether you are a start-up candy brand or a large candy manufacturer, candy equipment such as a gummy mold machine and soft candy packaging machines are indispensable production tools. If you need other candy equipment (such as lollipop forming machines, continuous marshmallow aerators, etc.), please contact professional equipment suppliers to tailor efficient candy production solutions for you.

This is a comprehensive candy production guide, covering the use of candy depositing machines and soft candy packaging techniques, helping you to efficiently make and package a variety of soft candies and providing professional support for your candy production line.

Continuous Marshmallow Aerator

Lollipop Forming Machine