Toffee is loved by consumers all over the world for its rich milky aroma and crispy taste. If you are looking for reliable equipment to mass-produce delicious toffee, a high-quality toffee making machine is an indispensable tool for you. Today, we will bring you a detailed recipe for making toffee around the use of toffee machine. Through this article, you can learn how to easily make high-quality toffee with a toffee candy machine, and at the end, learn more about related candy production equipment to help you expand your production line.

Gondor Toffee Making Machine

Toffee Production Line Equipment

Detailed Steps for Making Toffee

Turn on the toffee machine and adjust the temperature to the set value (generally 150 degrees Celsius) to ensure that the machine is preheated evenly. The preheating process helps the toffee mixture to heat up quickly when it is put in, avoiding unstable sugar content due to uneven temperature.

Pour white sugar and water into the heating tank and heat until the syrup is dissolved. Using the automatic stirring function of the toffee machine can prevent the syrup from being over-caramelized during heating.

When the syrup is dissolved and slightly cooled, gradually add butter and stir. After the butter is melted, slowly add heavy cream and continue to stir until uniform. At this time, you can add a little sea salt to enhance the taste level of the toffee.

Heat the mixture to 150 degrees Celsius and stir it continuously until it presents a shiny golden color. The temperature sensor in the machine can accurately control the temperature to prevent the toffee from overheating.

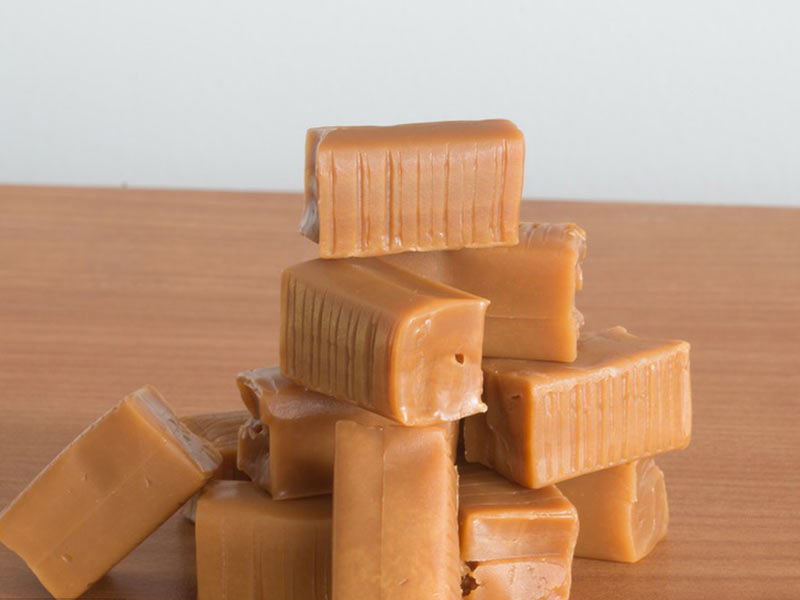

Pour the mixture into a molding trough or silicone mold, and cut it into blocks after cooling.

After the toffee has completely cooled, remove it from the mold, cut it into small pieces and wrap it with wax paper to prevent sticking.

Advantages of Using a Toffee Candy Machine

Debugging and Maintenance of Toffee Machine

During the production process, the debugging and maintenance of toffee machines are crucial. Here are some tips to help you better maintain the machine:

After each production, clean the machine with warm water and a clean rag to ensure that no residual syrup remains and avoid contaminating the new toffee when it is used next time.

The temperature sensor is an important part of the production process. It is recommended to calibrate it regularly to ensure the stability of the heating process of the toffee.

If the machine is used for a long time, it is recommended to lubricate and maintain the machine, especially the stirring parts, to ensure that it works smoothly.

Extension Equipment Recommendation

Making toffee is just a starting point for dessert making. For dessert lovers who want to make other types of candies, other related equipment can also be considered:

- Automatic Chocolate Tempering Machine: If you are interested in chocolate candies, you can consider adding a chocolate machine to achieve creative desserts such as chocolate-wrapped toffee.

- Gummy Candy Machine: Making fruit-flavored soft candy is also a delicious choice. When mixed with toffee, it can form a unique double-layer candy taste.

- Candy Packaging Machine: An indispensable auxiliary equipment for mass production, which can quickly package candies, extend shelf life, and facilitate sales and storage.

Gondor Automatic Chocolate Tempering Machine

Gondor Gummy Making Machine

Start Your Toffee Production Journey with Gondor Toffee Candy Machine

With this toffee machine recipe, plus other candy auxiliary equipment, your candy production line will provide a steady stream of sweet delicacies to the global market. We also provide you with a full range of candy making equipment to meet your production needs and help you easily make candy products that customers love.