As global chocolate consumption grows, the demand for efficient equipment in the chocolate manufacturing industry also increases. Technological innovation in each production link directly affects chocolate’s quality and production efficiency. Chocolate making machine manufacturers are seeking more precise and efficient equipment to increase production capacity and meet the market demand for high-quality chocolate. This article will introduce the latest trends in key equipment in the chocolate industry to help you choose the most suitable equipment to optimize your production process.

Innovation and Development of Chocolate Making Machine Manufacturers

As the chocolate market demands change, chocolate making machine manufacturers continue to innovate to improve production efficiency and maintain the natural flavor of cocoa. Here are some key equipment innovations:

It is used to finely grind and homogenize chocolate raw materials to improve their taste and quality.

Tempering machines precisely control the temperature to ensure that chocolate has the ideal gloss and taste.

Digital control is used to adjust the mold shape and production speed to meet personalized needs.

Fully automated production lines improve efficiency and ensure consistency of each batch of products.

Cacao Nibs Grinder: Improves Cocoa Nibs Processing Efficiency

Cacao nibs grinder is a key piece of equipment in chocolate production. It is responsible for grinding cocoa nibs to the ideal fineness, which directly affects the quality of cocoa powder. Modern cacao nib grinders not only use advanced cooling grinding technology to avoid frictional heat that affects flavor but also have the characteristics of high production capacity and low energy consumption, which greatly improves production efficiency and reduces operating costs.

Cacao Grinding Machine: Essential Equipment for High-Precision Grinding

The cacao grinding machine is an indispensable and important equipment in chocolate production. It is mainly used to further grind cocoa nibs to a fine degree suitable for making chocolate. During the grinding process, it helps to maximize the retention of the natural flavor and fat of cocoa, which directly affects the taste of chocolate. The following are the key features of this type of equipment:

Cacao Bean Roaster: The Key to Improving the Flavor of Cocoa Beans

Cacao bean roaster plays a key role in chocolate production, directly affecting the taste, aroma, and color of chocolate. Temperature and time control during the roasting process determines the flavor level of cocoa beans, so precise roasting technology is essential to ensure the high quality of chocolate. Modern roasters have improved production efficiency and ensured the consistency of chocolate through a series of innovative designs. Here are some key features:

Choose the Right Equipment to Improve Production Efficiency

Whether it is a cacao nibs grinder, cacao grinding machine, or cacao bean roaster, these equipment each play a unique role in chocolate production. Choosing the right equipment can help chocolate manufacturers improve production efficiency, reduce costs, and ensure the high quality of the final product.

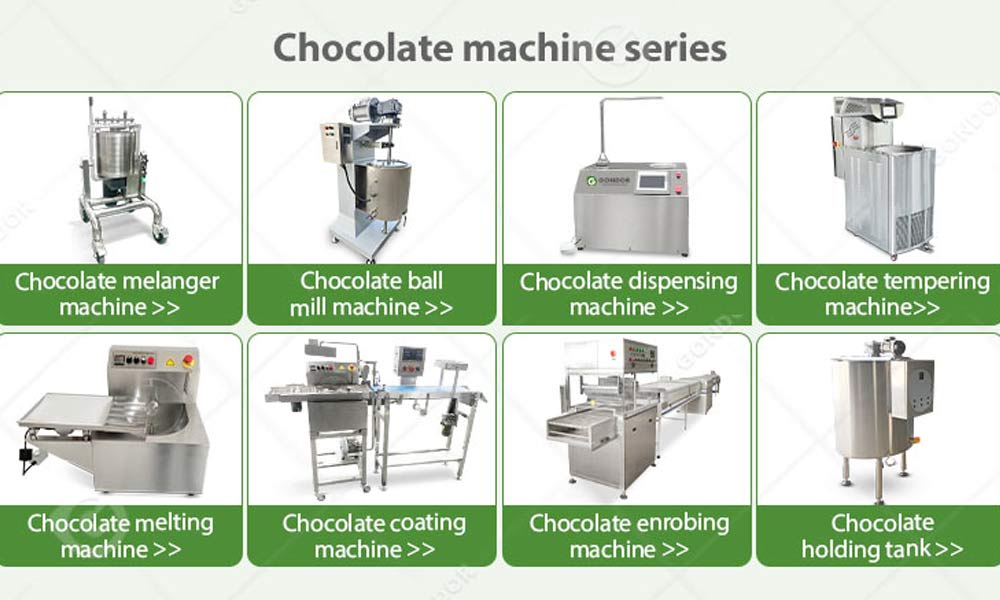

However, in addition to the above equipment, the chocolate production process also requires the cooperation of other auxiliary equipment, such as chocolate enrobing machines and chocolate tempering machines, which can further improve the taste and appearance of chocolate.

Comprehensive Equipment Support for Perfect Chocolate

As a leading chocolate-making machine manufacturer, we provide efficient, precise, and environmentally friendly equipment to help manufacturers improve efficiency and ensure quality. Every piece of equipment from Gondor is carefully designed. With technological advances, choosing the right equipment can optimize production and enhance brand competitiveness. Feel free to contact us for professional support and solutions.