In the modern food industry, efficient and automatic pastry equipment is becoming an important tool to improve productivity and ensure product consistency. A croissant making machine is specially designed to quickly and accurately form croissants, and it is ideal for all kinds of food processing places.

|

Model

|

Voltage |

Output |

Power |

Size |

Weight

|

|

GD-1

|

110V/220V |

1200-1800 pieces/hour |

0.2KW |

380*420*330MM |

35kg |

| GD-2 |

110V/220V |

1300-1800 pieces/hour |

0.55KW |

820*580*1080MM |

100kg

|

Applicable Industries of the Croissant Machine

The croissant making machine is a kind of professional equipment specially designed to improve production efficiency and maintain product consistency, which is widely used in many food processing industries:

Food Processing PlantsBakeriesCentral Kitchens of SupermarketsRestaurants & CanteensBaking Chains

In the mass production environment, croissant machine can automatically complete rolling, forming, rolling and other steps, greatly increasing the output, reducing labor costs, and ensuring the consistency of the size and taste of each product.

Suitable for small and medium-sized pastry shops. The machine is easy to operate and occupies a small space. The output can be flexibly adjusted according to the order to meet daily production needs.

Help the central kitchens to unify and standardize production, distribute fresh baked products to stores, and ensure food safety and efficiency.

Provide a fast and stable croissant forming scheme for breakfast or special dessert, reduce the preparation time of the kitchen and improve the production speed.

Support centralized mass production, ensure the high uniformity of the taste and appearance of products among different stores, and effectively help the chain standardization management.

Performance Highlights of the Croissant Roller Machine

Automatic Rolling Forming

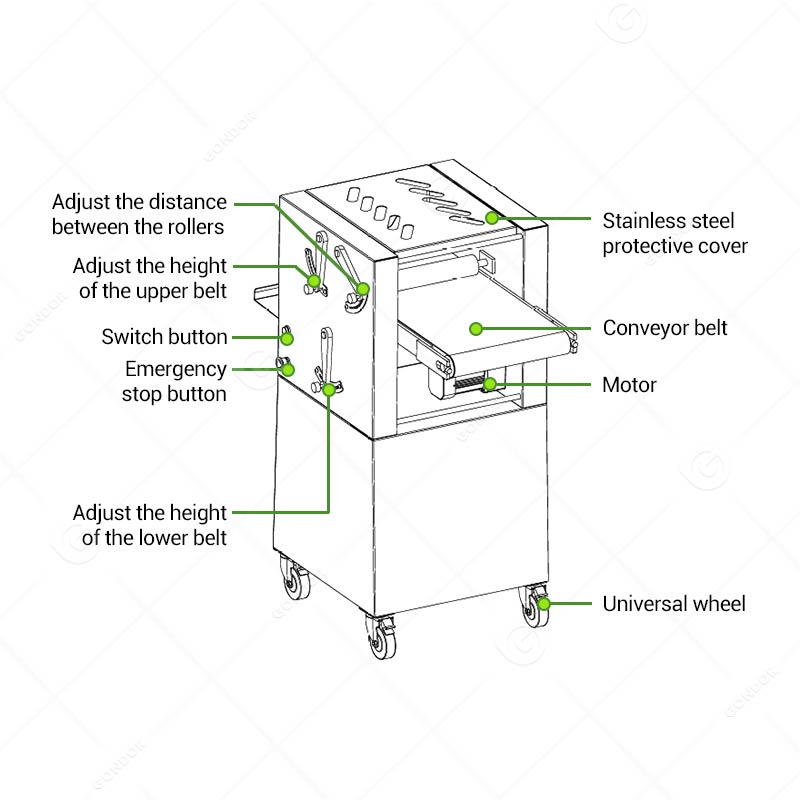

The triangular dough is placed on the conveyor belt and automatically enters the molding process. The whole machine can be operated with one button, and it can be started with one button and quickly formed in seconds.

Excellent Shaping Performance

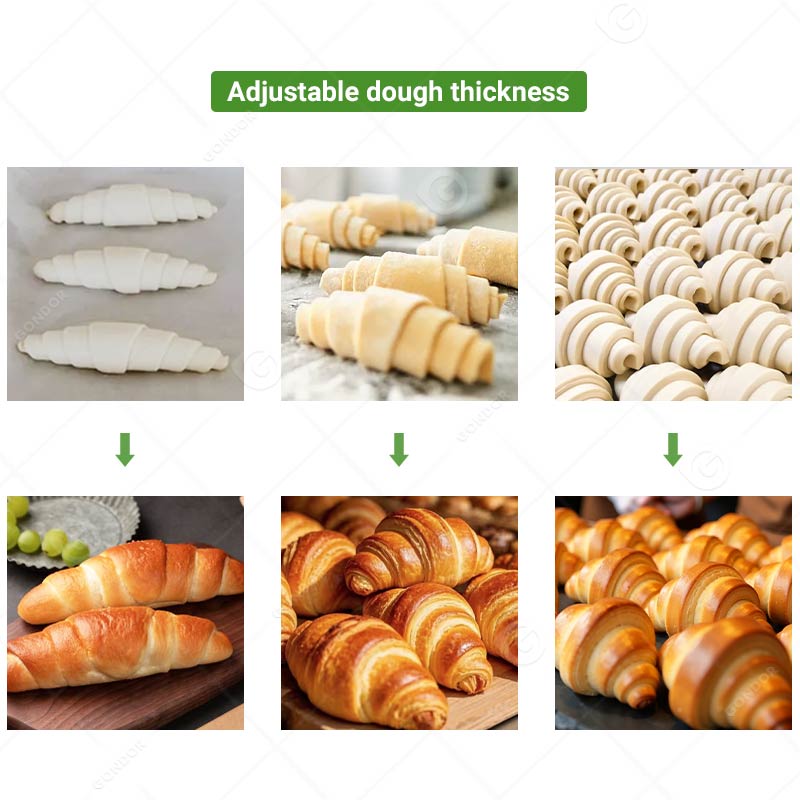

The mechanical structure simulating manual work is adopted, and the pressure roller and the upper and lower belt devices are adjusted so that the claw wrapping system is compact and natural, beautiful in appearance, and meets the high market standards.

Adjustable Speed Control

A built-in speed control button can freely control the discharging speed according to the production rhythm, flexibly meet the needs of different production quantities, and improve the overall efficiency.

Easy Disassembly & Cleaning

All components are designed with the convenience of daily maintenance in mind, and the machine is easy to disassemble, saving cleaning and maintenance time and meeting high-frequency usage scenarios.

Durable & Long Lifespan

The core components, such as the pressure roller, are made of 201 stainless steel, which is corrosion-resistant and deformation-free, and the whole machine is designed without wearing parts, with long service life, saving subsequent costs for enterprises.

More Equipment Options

If you are looking for a more complete pastry production solution, we also provide the following equipment.

Whether you are a start-up baking factory or a large food enterprise in the process of expansion and upgrading, we can provide a complete set of solutions. Contact us immediately to get more technical data and quotation information so that your croissant production can be easier and more efficient! Croissant making machine, let delicious food not wait!