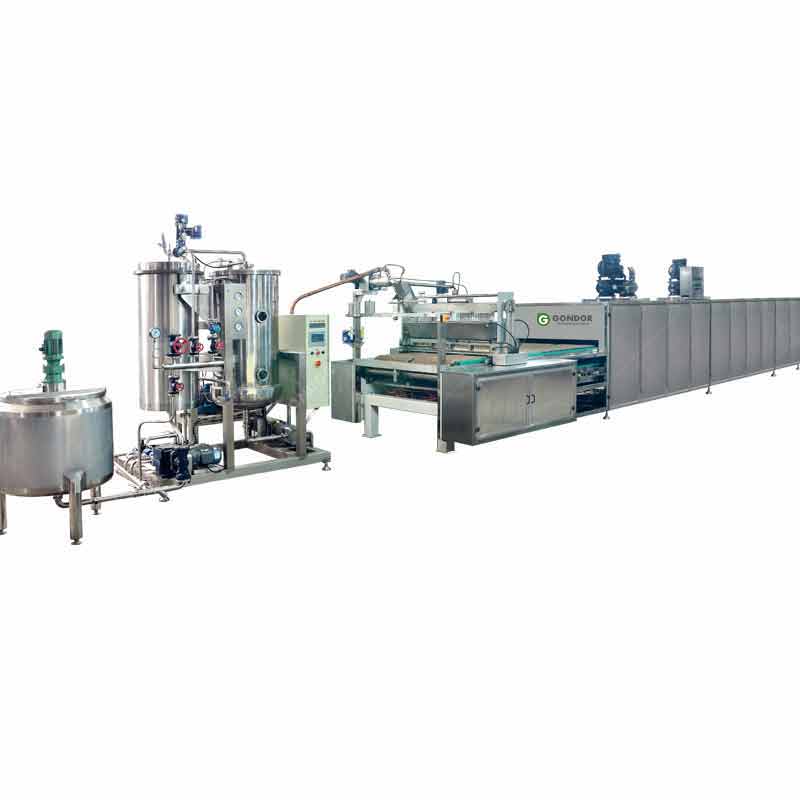

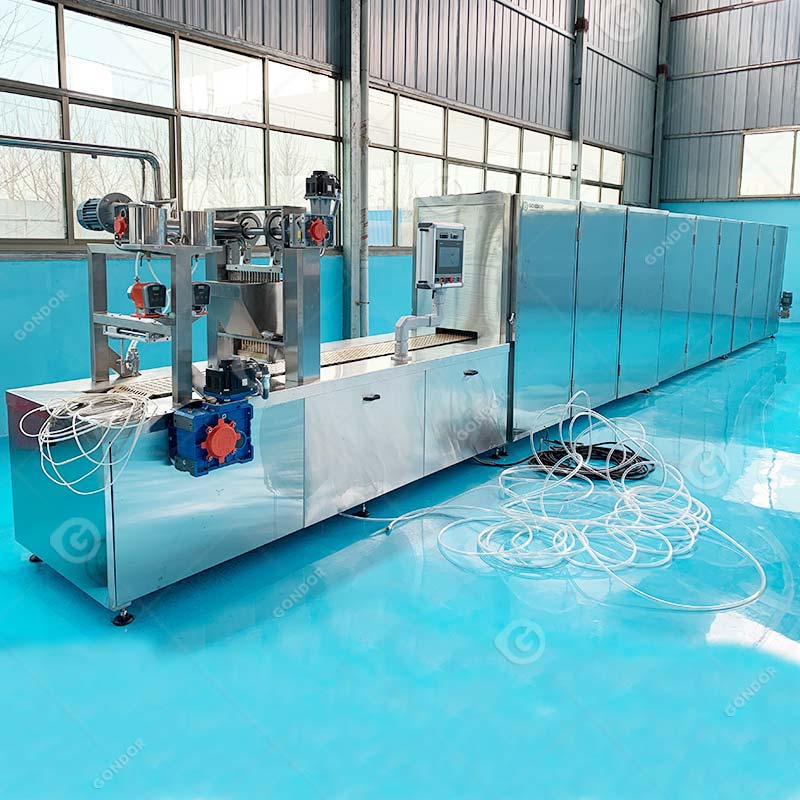

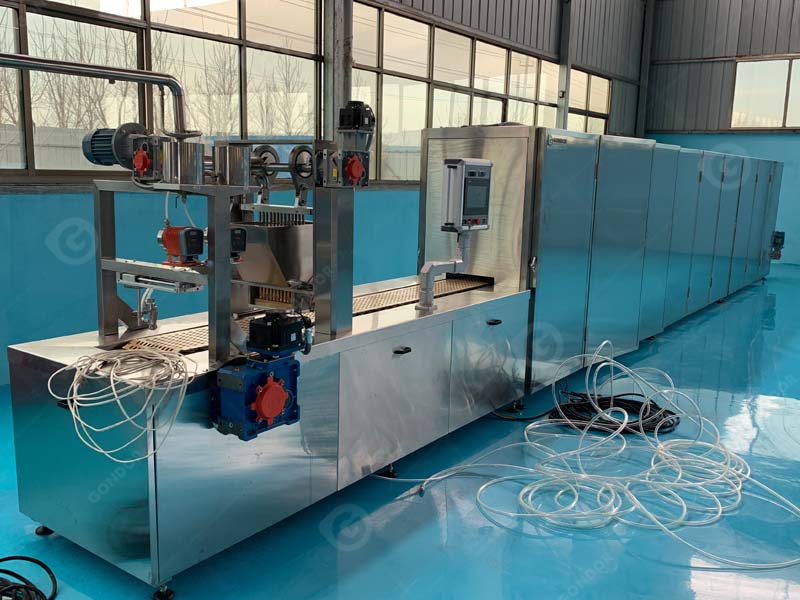

Gondor machinery provides a cost-effective gummy candy making machine for the competitive confectionery market with high automation and output. And it is an ideal piece of confectionery equipment for the continuous production of gelatin-based candies. Created with cutting-edge production processes and technologies, our gummy making machine can produce gummy candies in various shapes and colors. Besides, the gummy candy making machine for sale in Gondor can guarantee the stable gummy quality, reduce the space usage, and save labor costs, which can greatly lower the overall production costs for our clients. Therefore, Gondor gummy making machines are the optimal solutions for your small-scale to large-scale candy production! Choose Gondor machinery to start your gummy making project and we will always be here to assist you all!

Professional Gummy Candy Making Machine for Sale in Gondor

Why Choose Gondor Gummy Candy Making Machines?

As the gummy candies enjoy worldwide popularity, the demand for superior gummy making machines continues to rise. Moreover, in today’s highly competitive candy processing market, many manufacturers choose to invest in the advanced gummy candy machines and can gain a significant advantage. Thus, a growing number of businesses are deciding to invest in gummy candy making machines. Here, we will highlight the unique features and benefits of our innovative gummy production line, which makes it a perfect option for investors looking to streamline their gummy manufacturing operations. Check below for the top benefits of choosing gummy candy making machines from Gondor machinery:

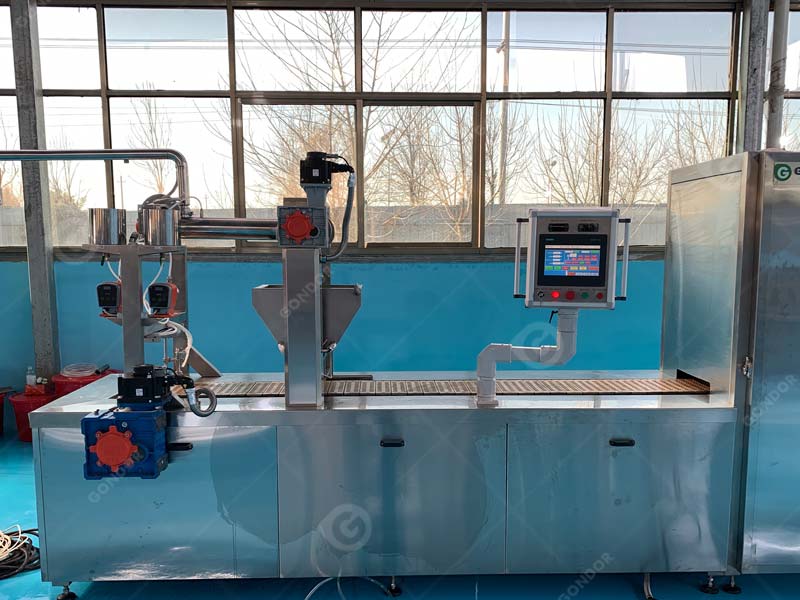

Automated Control System

We adopt an advanced programming system for our gummy making machine to control the essential parameters automatically. For example, the vacuum boiling temperature, cooking time, holding temperature, and pouring speed can be adjusted according to specific needs, which will ensure the uniform candy quality and reduce the likelihood of human error, more efficiently.

Intuitive Touchscreen Interface

The touchscreen control panel for gummy candy machine is user-friendly and operators can view the entire process flow and monitor the status of each component with ease. And it is easy to set and display many parameters, such as temperature and pouring speed, which make it simple to operate the production line, minimize the training time and maximize productivity.

Seamless Demolding of Gummies

Our gummy candy machines are designed and optimized with a robust conveyor system, cooling systems, and dual demolding mechanisms, which can ensure the seamless demolding of gummies. And these designs work together to maintain the shape and texture of the gummy candies, which can greatly reduce the production downtime and enhance overall efficiency.

Variable Frequency Drive

Gondor gummy candy making machines adopt variable frequency speed control and this can ensure the precise control over the syrup flow rate. So, the candy quality will be guaranteed. Meanwhile, the consistent syrup flow will greatly reduce the waste in the candy manufacturing and ensure that each gummy batch meets the highest standards.

Precise Dosing and Mixing

As for the gummy candy making machine, there is a dynamic mixer that can automatically perform the precise online dosing and mixing of flavors, colorants, and acids. The integration ensures that the ingredients are evenly distributed to produce eye-catching and tasty gummies that can attract consumers for investors to maximize their profits.

Flexible Production Capacity

At Gondor machinery, we offer gummy production line with flexible production capabilities, and the output for our gummy making machine is ranging from 150 to 600 kilograms per hour. Therefore, investors who buy our machines can adjust the production levels according to their demands, optimizing resource utilization and meeting market needs efficiently.

Chocolate Filling System

We also provide gummy production line with an optional chocolate filling system, which just meets some investors’ demand to diversify their product offerings with minimal disruption. This filling system enables the production of chocolate-filled gummies, as well as adds a luxurious twist to traditional gummy candies, which can appeal to a broader audience for them.

Versatile Candy Shapes

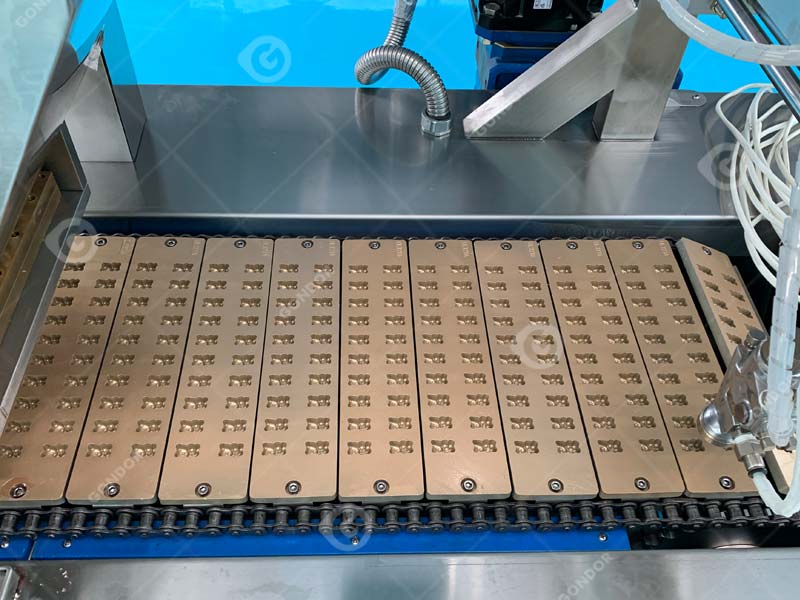

Due to its adaptable mold design, our gummy production line can produce gummy candies in a wide variety of shapes, which will cater to diverse market preferences. From traditional gummy bear shapes to customized designs, the mold options we offer allow candy manufacturers to innovate and capture consumer interest with unique products, more competitive.

Candy Making Machine for Gummies

Gummy Candy Factory Equipment

Gummy Candy Processing Equipment

Gummy Candy Production Line for Sale

Gummy Making Machine: Product Classification

Gummy making machines can produce gummy candies in different shapes, sizes and flavors, which are enjoyed by all ages worldwide. As for gummy manufacturers or investors in confectionery industry, it is important to understand how to classify the gummy candy making machines and choose the right machine to produce high-quality gummies efficiently. Here, we will explore the various classifications of Gondor gummy making machines based on product types, which aims to help our clients make informed decisions to meet your gummy production needs.

- Large-scale Gummy Making Machines: They have high production capacity and automation levels, which are widely used by large gummy manufacturing enterprises for large batch production.

- Medium & Small Gummy Machine: With lower production volumes and higher flexibility, it is designed for small and medium-sized candy manufacturers or specific markets to produce gummies.

- Fully Automatic Gummy Production Lines: With highly automated production processes, the gummy candy machine requires minimal manual intervention from raw material handling, ingredient mixing, cooking, and molding, to packaging.

- Semi-automated Gummy Processing Lines: It is suitable for less production needs or investors with limited budgets. In the production process, some are automated while others require manual operation.

- Pectin Gummy Making Machine: It involves the mixing and cooking of pectin to produce pectin gummies, which are appreciated for their plant-based ingredients, health benefits, and ability to cater to various dietary needs.

- Gelatin Gummy Candy Machine: It can produce gelatin-based gummies, such as gummy bears, gummy worms, gummy rings, sour gummies, vitamin gummies, themed gummies, and functional gummies.

- Starch Gummy Making Machine: It is specifically designed for producing gummies using starch as the main gelling agent to meet market demands, which involves the gelatinization and molding of starch.

- Molded Gummy Production Lines: This gummy machines use molds to shape and produce gummies, which are ideal for creating gummies in diverse shapes and sizes. These themed gummies include shapes like animals, fruits, or other custom designs.

- Cutting Gummy Production Lines: The gummy machines adopt candy cutting machines to shape gummies, which is suitable for producing strips or block-shaped gummies. The production line is especially effective for high-volume production or bulk packaging.

- Bulk Packaging Gummy Making Machines: It is suitable for mass production and bulk sales. At the ends of the production lies, there is a bulk packaging machines, which can ensure gummies are packaged quickly and accurately, ready for distribution.

- Individual Packaging Gummy Candy Machines: They are designed for packaging gummy candies into individual portions, which cater to the retail market and provide convenient, single-serving packages to suit the different market needs.

- Steam-heated Gummy Making Machine: It uses steam as the primary heating method, suitable for large-scale production with high thermal efficiency. In factories, it can effectively reduce energy consumption and production costs for investors.

- Electric-heated Gummy Candy Making Machine: With electric heating equipment, it can achieve rapid heating and cooling for medium and small-scale production. The precise temperature control can ensure consistency and quality stability.

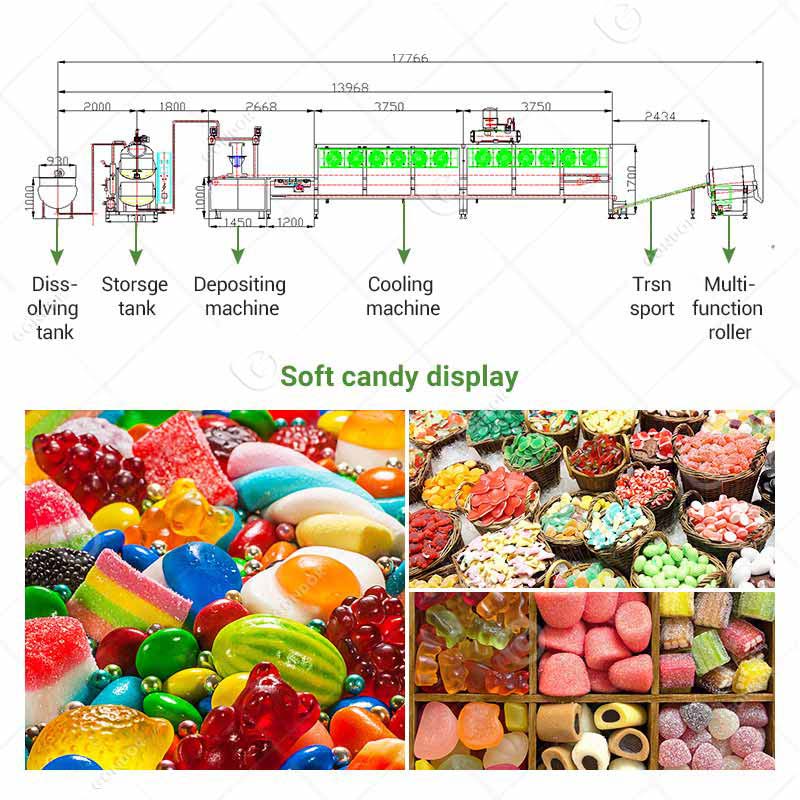

Gummy Making Machine Structures and Corresponding Functions

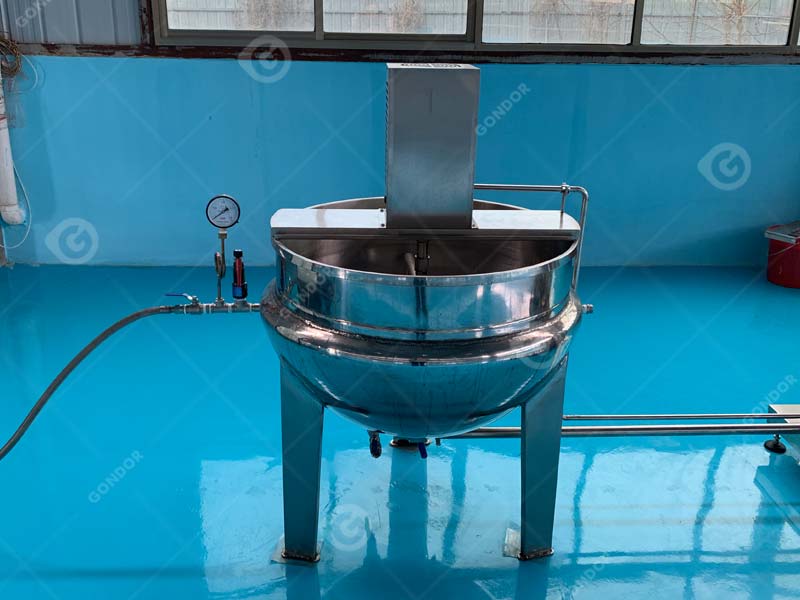

Gummy making machines are complex systems composed of several key structures, each playing a vital role in the gummy manufacturing process. In order to purchase a suitable gummy making machine for your project, investors had better understand the main structures and the function of each piece of equipment in the gummy production line. Choosing the right production lines can not only enhance productivity, ensure product consistency, and reduce operational costs, but also boost your business for long-term success. Here, Gondor will explain the structures and their roles in the soft candy manufacturing to help our clients select the appropriate gummy machines. Please feel free to leave a message on our website or WhatsApp to seek assistance from our professional project manager or technical team.

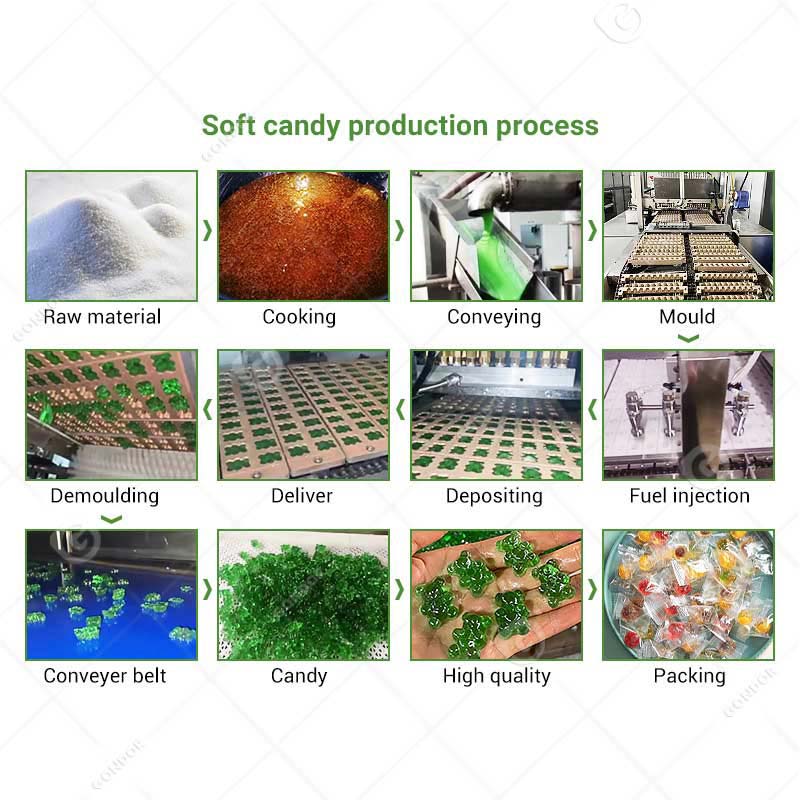

How are Gummy Candies Manufactured?

Gummy candy making machines can produce various gummy candies effectively. It combines different precise machinery with the gummy candy manufacturing, which is a complex process. It involves several key steps, from the preparation of the base ingredients to the final packaging. At Gondor machinery, our gummy making machines can ensure the consistency, quality and efficiency in the whole process of gummy candy production. No matter what you are operating, a small-scale production or a large manufacturing facility, it is essential to understand the workflow of gummy candy machines, which can help you make an informed decision. Here’s an overview of how gummy candies are made:

Gondor Machinery – Top Gummy Candy Making Machine Manufacturer

Are you interested in purchasing gummy candy making machines for your business? Gondor machinery will be the optimal selection when you are looking for a candy making manufacturer for your gummy business. In our company, you can not only buy a high-quality, reliable, and technologically advanced confectionery machinery, but also obtain support from our excellent customer service and industry expertise. Therefore, choosing Gondor machinery for your gummy making machine can guarantee you can succeed in the gummy candy industry. Here is a detailed analysis of why Gondor might be the best choice to meet your gummy production needs:

Reputation and Experience

As a professional manufacturer, Gondor is reliable and famous for our extensive experience, well-established expertise, strong market reputation and proven track record of satisfied customers.

High-Quality Machines

Our gummy candy machines adopt the food-grade stainless steel to ensure the durability and hygiene. Besides, we apply the latest technology to the machine, such as automated depositing and precise temperature control.

Customization and Flexibility

Customization is available in Gondor machinery. Our clients can choose and tailor the machine to match their production needs, such as the mold designs, production capacities, or specific automation features, and so on.

Competitive Pricing

In Gondor, we offer a competitively priced gummy candy machines not the cheapest when considering the quality, durability, and advanced features. So, the long-term value and return on investment from purchasing a Gondor machine are substantial.

Support & Service

The comprehensive support in Gondor machinery includes installation guidance, operator training, and ongoing technical support to ensure the smooth operation. We also offer reliable after-sales service, including the availability of spare parts, maintenance services, and warranty coverage.

Compliance & Certification

In order to win the trust of our clients, we also provide all necessary certifications and compliance, such as CE and FDA, which can meet international food safety and quality standards. Meanwhile, we constantly upgrade it to help you maintain compliance and competitive advantage.

Positive Feedback

Gondor has received positive feedback from global clients, which proves the reliability and effectiveness of our gummy making machines. As a leader in the confectionery industry, Gondor machinery also won many awards and is widely recognized by the industry.

Global Presence

At Gondor machinery, we have customers across the globe. No matter where you are, they have access to our products and services for our global clients. Besides, we can ensure the shipment, maintenance, and repairs for our worldwide clients can be handled promptly and efficiently.

Profitable Investment with Gondor Gummy Candy Making Machine

Planning to expand your gummy candy production and maximize the profits of your business? Gondor machinery will assist you here with our superior gummy candy making machines! Whether you’re starting a new business or scaling up, our gummy making machine is just for you and it is designed to streamline the production process, as well as improve the efficiency and precision of gummy manufacturing. Don’t miss out on this opportunity to elevate your gummy candy business and contact us today to get a quote and take the first step towards success!

In addition, except for various confectionery machinery, there are various production lines, and different food processing and packaging machinery in our factory. No matter what you need, snack making machine, meat processing machinery, fruit and vegetable processing machinery, grain and pasta processing machinery, and so on. Check here to contact us for a suitable food processing machinery to boost your investment!