Global Surge in French Fry Production Investment

As the frozen food industry continues its rapid expansion, demand for advanced french fry production line equipment is hitting record highs in 2025. Manufacturers across Asia, Europe, and the Americas are investing heavily in automated systems to improve efficiency, reduce labor dependency, and meet the growing global appetite for French fries. From cloud kitchens to mega food processors, businesses are re-evaluating production technologies to stay competitive, driving innovation and changing pricing dynamics throughout the sector.

Rising Consumption and Shifting Consumer Behavior

French fries remain one of the world’s most consumed fast foods, but recent changes in consumption habits—especially the boom in online food delivery and quick-service restaurants—have significantly boosted the need for reliable potato processing equipment. Industry analysts report that global frozen French fry consumption is expected to grow steadily over the next five years.

Automation and Digitalization Define the 2025 Equipment Landscape

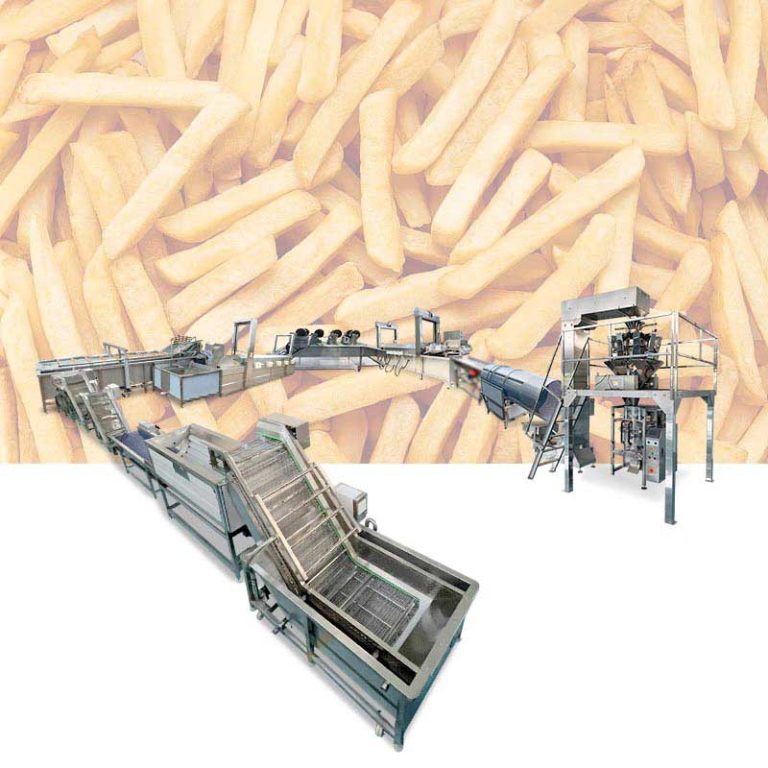

Modern french fry production lines are no longer simple cutting-and-frying systems. Instead, they incorporate advanced automation technologies such as:

- Intelligent washing and peeling systems

- Precision cutting and uniform sizing equipment

- Automated blanching, de-watering, and frying chambers

- Energy-efficient freezing systems for frozen fries

- Smart packaging and traceability integration

Growing Popularity of Small Scale Frozen French Fries Production Lines

Not every factory requires a massive processing plant. In fact, one of the most notable industry shifts in the last two years is the rising popularity of small scale frozen french fries production line systems. These compact lines are designed for:

- New entrants in the frozen food market.

- Regional suppliers targeting local supermarkets.

- Investors in emerging markets.

- Restaurants or central kitchens expanding into retail frozen fry production.

Such small-scale lines allow companies to start with lower capital expenditure while still maintaining industrial-level output quality. More processors are embracing pilot-scale or modular designs that can be expanded as demand grows. This flexibility has contributed to rapid adoption among developing regions where initial investment budgets are typically more conservative.

Factors Influencing French Fries Production Line Price

The french fries production line price continues to vary widely, largely based on equipment capacity, automation level, and customization needs. Key factors include:

Smart, Sustainable French Fry Production

The global french fry processing sector is undergoing a transformational shift driven by automation, sustainability demands, and expanding consumption. As businesses evaluate the french fries production line price and consider their investment options, flexible and scalable systems are becoming essential. Whether through compact small-scale lines or high-capacity fully automated plants, the market is moving toward smarter, greener, and more efficient production solutions.With evolving technologies and rising global demand, the potato chips production line market is set for continued growth and innovation in the years ahead.