Starting with a glass of milk: What exactly does a yogurt-making machine do?

Yogurt is essentially a product of “milk + beneficial bacteria + time and temperature control.” In a suitable temperature environment, lactic acid bacteria break down lactose in milk into lactic acid, causing milk proteins to coagulate, forming yogurt with a sour taste and thick texture.

The functions of a yogurt-making machine are actually quite “specific”:

1. Provide a stable and suitable fermentation temperature (usually in the range of approximately 35–45℃);

2. Maintain a constant temperature within a set time, allowing lactic acid bacteria to work slowly;

Commercial equipment also incorporates heating and sterilization, cooling, heat preservation, and cleaning processes to achieve large-scale, standardized production.

From a food machinery perspective, a qualified yogurt-making machine is essentially a control system that creates the optimal working environment for “living microorganisms.”

The scientific basis of milk turning into yogurt: The secret of lactic acid fermentation

To understand the working principle of a yogurt-making machine, we must first understand “what the microorganisms are doing,” a process that involves three steps. 1. Inoculation with Lactic Acid Bacteria: Adding a starter culture (active lactic acid bacteria powder) or pre-made yogurt containing live bacteria to pasteurized milk is called “inoculation.” Commonly used starter cultures include “Lactobacillus bulgaricus” and “Streptococcus thermophilus”.

2. Lactose to Lactic Acid Conversion: At suitable temperatures, lactic acid bacteria multiply rapidly, breaking down lactose into lactic acid. The pH gradually decreases from approximately 6.6 to around 4.5, resulting in a sour taste and thick consistency.

3. Formation of Protein Network Structure: Casein in milk unfolds and aggregates in an acidic environment, forming a three-dimensional network structure that “locks in” water—this is the gel structure of yogurt. Preheating the milk to 80–90°C denatures some whey proteins, allowing them to participate in this network structure, resulting in a smoother, thicker yogurt.

The function of a yogurt-making machine is to precisely control the temperature and time, ensuring these biochemical reactions occur under safe and stable conditions.

How does a yogurt maker work?

Whether it’s a small home yogurt maker or a commercial yogurt maker used in food factories, its core working principle can be summarized in one sentence: providing and maintaining a constant and suitable temperature environment for lactic acid bacteria fermentation.

A typical yogurt maker usually includes:

Heating and temperature control system: Uses electric heating elements or heating plates to heat the fermentation chamber or fermentation tank to the set temperature, preventing slow fermentation or even failure due to excessively low temperatures.

Temperature sensing and control unit: Temperature sensors monitor the temperature of the chamber or fermentation liquid in real time, and the control board adjusts the heating power to stabilize the temperature within a suitable range (e.g., 40–42℃). High-end models may have the probe directly contacting the bottom of the fermentation cup for improved temperature control accuracy.

Insulation and uniform heat distribution design: The machine’s outer shell is typically made of high-quality insulation materials, acting like an insulated box to minimize internal heat loss, ensure efficient energy utilization, and maintain a uniform temperature throughout the inner container. Whether it’s a yogurt maker with individual cups or an integrated inner container, its design aims to ensure that every portion of the milk is under the same fermentation conditions.

Time Control and Program Settings: Users can set the fermentation time (e.g., 6–12 hours), and some devices support multiple programs (preheating, fermentation, cooling).

Food Contact Components: Components in contact with milk are typically made of stainless steel (e.g., 304) or food-grade plastic to meet food safety and easy-to-clean requirements.

The entire system works collaboratively to ensure that the milk is consistently maintained within the optimal temperature range for lactic acid bacteria within the predetermined time, ensuring both thorough and safe fermentation.

How does a yogurt maker turn milk into yogurt step by step?

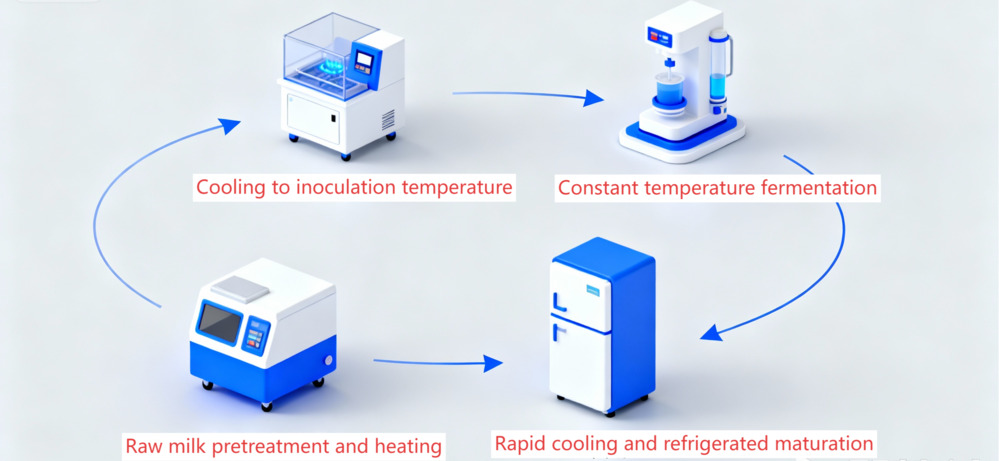

Having understood the working principle of a yogurt maker, let’s look at how a yogurt maker completes this conversion process step by step. A yogurt maker typically completes the following four steps:

1. Raw Milk Pretreatment and Heating

The milk is filtered and standardized (adjusting the fat and protein content). Some processes add milk powder to increase the protein content, making the yogurt thicker.

Sterilization: Eliminates any unwanted bacteria in the milk, preventing them from competing with lactic acid bacteria and affecting fermentation.

Denimized Whey Protein: Moderate heating denatures whey protein, thereby enhancing the water-holding capacity of the milk, making the finished yogurt thicker, and preventing whey separation.

Evaporation of Some Water: Slightly concentrates the milk.

2. Cooling to Inoculation Temperature

The milk is cooled to 40–45℃ using cooling water or a plate heat exchanger, which protects the activity of lactic acid bacteria and facilitates rapid fermentation. If the temperature is too high, it will kill the lactic acid bacteria; if the temperature is too low, fermentation will not start. After thoroughly mixing the starter culture, pour the milk into the inner container of the yogurt maker or into individual cups.

3. Constant Temperature Fermentation

Start the fermentation program on the yogurt maker. The equipment automatically controls the temperature to maintain it within a range of approximately 35–45°C, allowing the lactic acid bacteria to multiply stably.

Over the next 6 to 10 hours, the lactic acid bacteria will enter an exponential growth phase, breaking down lactose to produce lactic acid. You will observe the milk gradually thickening and emitting a slightly sour aroma.

4. Rapid Cooling and Refrigerated Maturation

After fermentation, the machine will indicate or automatically stop heating. At this point, you have a set yogurt, but the flavor is still mild. Immediately transfer the yogurt to the refrigerator (around 4°C) for at least 2–4 hours. During refrigeration, the yogurt structure will further stabilize, and the flavor will continue to develop.

Low temperatures significantly slow down the activity of lactic acid bacteria, preventing yogurt from becoming too sour, while allowing flavor compounds to continue maturing, resulting in a richer and smoother taste.

Key Considerations When Choosing a Yogurt Making Machine

Temperature Control Accuracy and Uniformity

- Can it stably maintain a fermentation temperature range of 35–45℃?

- Is there a reliable temperature sensor layout to prevent localized overheating or undercooling?

Materials and Hygiene Design

- Are parts in contact with materials made of food-grade materials (e.g., 304 stainless steel)?

- Are the tank and piping easy to clean, with no dead corners, and does it support CIP online cleaning?

Process Compatibility

- Does it support multi-stage processes such as preheating, heat preservation, and rapid cooling?

- Can the program be adjusted according to the needs of different strains of bacteria and different products (set-type, stirred-type, flavored-type)?

Energy Consumption and Capacity Matching

- Does the equipment capacity match the target output?

- Does it have an energy-saving design to reduce power consumption while maintaining a constant temperature?

Stability and Traceability

- Can the control system record key process parameters to provide data support for subsequent quality tracking?