As the chocolate market continues to expand and consumers’ requirements for quality increase, chocolate production equipment is also constantly being updated. Chocolate manufacturing machine price, cocoa melanger, and chocolate manufacturing processes have become hot topics in the industry. This article will briefly explore these three topics and take you to understand the latest developments in chocolate manufacturing.

The Changing Trend of Chocolate-Making Machine Prices

The price of chocolate-making machines has become diversified as technology advances and market demand grows. Depending on the function, size, and brand of the equipment, the price usually ranges from a few thousand dollars to hundreds of thousands of dollars. When choosing equipment, the chocolate manufacturing machine price is certainly important, but factors such as production efficiency, equipment durability, and after-sales service also need to be considered.

Cocoa Melanger: The Core Equipment of Chocolate Production

Cocoa melanger plays a vital role in chocolate production. It is mainly used to mix and grind cocoa beans with raw materials such as sugar and milk powder to ensure the uniform texture and ideal taste of chocolate paste. Modern cocoa blenders use advanced technology to accurately adjust the temperature and mixing speed to ensure the quality of chocolate. For large-scale manufacturers, choosing an efficient and stable blender is the key to improving production efficiency and product quality.

There are many types of cocoa blenders on the market, ranging from small manual equipment to large industrial production lines, suitable for the needs of enterprises of different sizes. Startup brands can choose small and medium-sized equipment, while large-scale manufacturers may need multiple industrial-grade blenders to ensure consistency and efficient production.

Chocolate Manufacturing Process: The Delicate Process from Beans to Chocolate

The chocolate production process is the key to ensuring the quality of chocolate. It includes the whole process from the processing of cocoa beans to the formation of the final chocolate product. The following is a typical chocolate production process:

Related Equipment Recommendation: Improve Production Efficiency

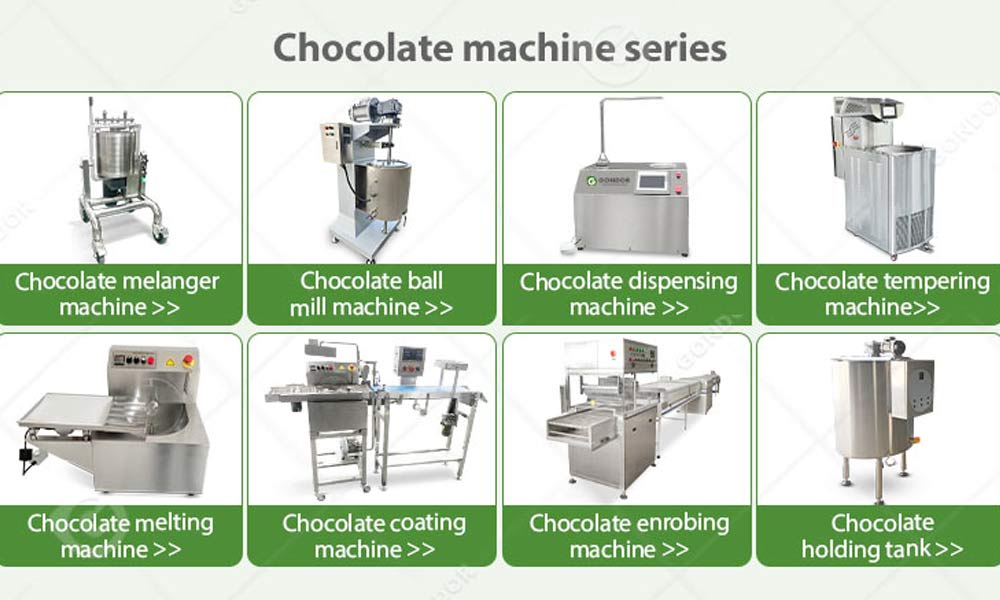

In addition to chocolate-making machines and cocoa mixers, many other related equipment in the chocolate production process can help companies improve production efficiency. For example:

The chocolate ball mill finely grinds and mixes cocoa paste and powdered sugar, creating a smooth, uniform chocolate paste that enhances flavor and texture.

Used to mold chocolate products of different shapes and sizes to meet the market demand for diversified products.

Used to quickly cool chocolate products to ensure chocolate’s structural stability and gloss.

These equipment work together to form an efficient and modern chocolate production line, providing manufacturers with more efficient and sophisticated production solutions.

Choose the Right Equipment to Help Upgrade Chocolate Production

Whether it is an efficient chocolate-making machine or a cocoa mixer that improves quality, companies should choose production equipment according to their own needs. With the continuous innovation of technology and processes, the chocolate industry will continue to develop and bring more high-quality products to consumers around the world. If you need to know the appropriate production equipment or have any questions, please contact Gondor Machinery. We will provide you with professional technical support and equipment recommendations.