The chocolate industry is experiencing technological innovation, especially in the field of industrial production. As demand grows, manufacturers are paying more and more attention to equipment efficiency and product quality. Industrial chocolate-making equipment has therefore become a focus. These advanced equipment not only increase production but also ensure the quality of chocolate. This article will focus on the best chocolate melter machine and automatic chocolate tempering machine, and explore their key roles in modern chocolate production.

Industrial Chocolate Making Equipment

As the demand for chocolate increases, traditional production methods can no longer meet the needs of large-scale production. Modern industrial chocolate making equipment has greatly improved production efficiency and ensured the consistency of chocolate quality through automation and intelligence. The following are the main functions of these equipment:

These functions enable industrial chocolate making equipment to ensure a high quality of chocolate while improving production efficiency.

Best Chocolate Melter Machine

The melting of chocolate affects the taste and quality. The Best chocolate melter machine melts chocolate quickly and evenly through precise temperature control, avoiding overheating or clumping, and ensuring smooth and uniform chocolate. Here are the main features of the best chocolate melter machine:

Precisely adjust the melting temperature to avoid overheating or burning of chocolate.

Automated control of the melting process to improve operational convenience.

Reduce cleaning time, keep equipment hygienic, and improve production efficiency.

Ensures that chocolate melts evenly, avoiding clumping or partial unmelting.

Significantly shorten chocolate melting time and improve overall production efficiency.

Optimize energy consumption and reduce production costs.

Automatic Chocolate Tempering Machine

The tempering of chocolate is crucial to its taste and appearance. The automatic chocolate tempering machine ensures that the chocolate forms an ideal crystal structure during the cooling process by precisely controlling the temperature and maintaining the perfect taste and gloss. Unlike traditional manual tempering, the automatic tempering machine can monitor and automatically adjust the temperature in real-time to ensure the consistency of each batch of chocolate, improve production efficiency, and reduce human errors.

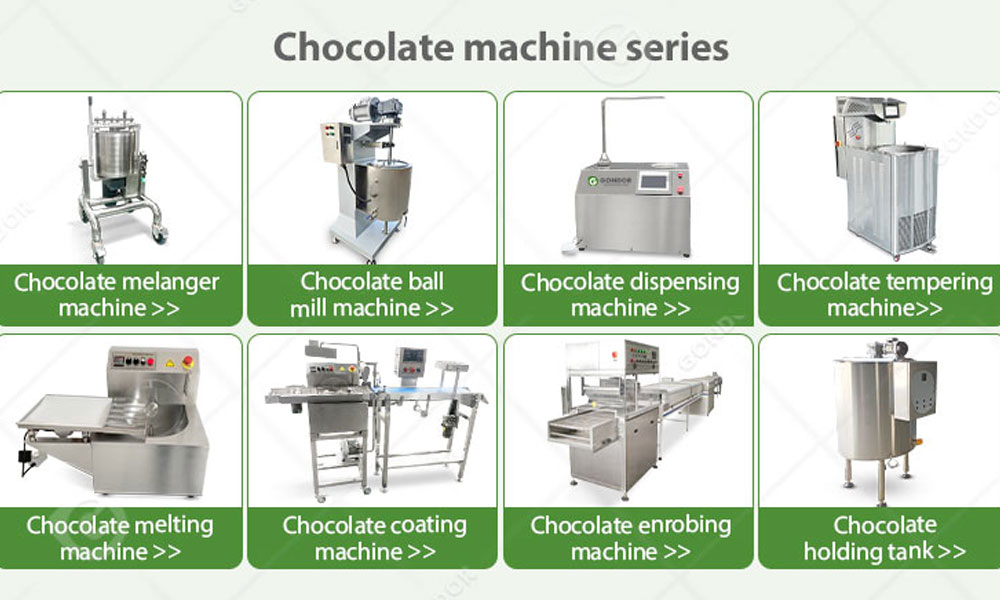

Comprehensive Support for Chocolate Production

In addition to melters and tempering machines, chocolate production also requires other key equipment, such as chocolate panning machines and chocolate stone grinders, which improve production efficiency while ensuring chocolate quality. Manufacturers should choose appropriate equipment based on scale, demand, and budget, and consider equipment performance and price. In addition, Gondor also provides customized services to meet the different needs of global customers.

Flexible Use Equipment to Win Market Competition

As technology advances, chocolate production equipment is also constantly innovating. If manufacturers can use it flexibly, they will stand out in the market competition. A complete production line also requires other equipment, such as coolers and coating machines, to achieve efficient and stable production to meet global demand.