In recent years, as the food processing industry has rapidly evolved, the demand for customized food processing equipment has continued to rise. Moreover, more and more manufacturers are turning to custom solutions, allowing them to produce distinctive final products and remain competitive in an intense market environment. Therefore, a client based in Santa Ana, California recently ordered a customized 3200L horizontal mixer, which has been delivered and installed successfully by Gondor machinery! From the initial inquiry to final delivery and installation, the project spanned several months and was completed by meeting the client’s specific requirements through the expertise in the design and customization of our company. Check more details below!

Gondor 3200L Horizontal Mixer in America

Project Background of Tailored Horizontal Mixer in the USA

- In 2023, we were introduced by one of our loyal clients to this customer. He has a well-established food processing company located in Santa Ana, California, USA. Additionally, the client has built a solid reputation in the local market, where they are widely recognized for their influence and success in the food processing industry. This connection was made through one of our long-standing Chinese partners, and the initial communication was carried out directly via WhatsApp, which allows for efficient and immediate dialogue.

- After a series of in-depth discussions, we learned that the client requires a mixing solution for their production process, which involves blending various powdered materials. Consequently, they have specific demands for the mixing equipment, particularly in terms of capacity, sealing efficiency, and customization options. After understanding the requirements of our customers from the USA, our project manager makes all efforts to offer tailored solutions that align perfectly with their operational goals and help optimize their production efficiency.

- Variable frequency stirring allows the adjustment of mixing speed according to different materials.

- High sealing performance can ensure that dust does not escape, which can maintain a clean production environment.

- A customizable discharge outlet is suitable for flexible application across different production lines.

Project Communication: Gondor Horizontal Mixing Machine

- After the client in the USA contacted us, our project manager promptly initiated communication with them. During the early discussions, the client outlined several key requirements for the mixing equipment, placing particular emphasis on sealing performance, dust control, and customization capabilities.

- Following that, our sales and technical teams held detailed discussions and proposed an initial mixing equipment solution, after carefully considering the client’s production line layout and mixing needs. Over a period of two months, through ongoing discussions with the technical team, the client gradually recognized our company’s expertise and the effectiveness of the proposed solution.

Order Secured Through 3D Drawings of horizontal mixer for sale in Gondor

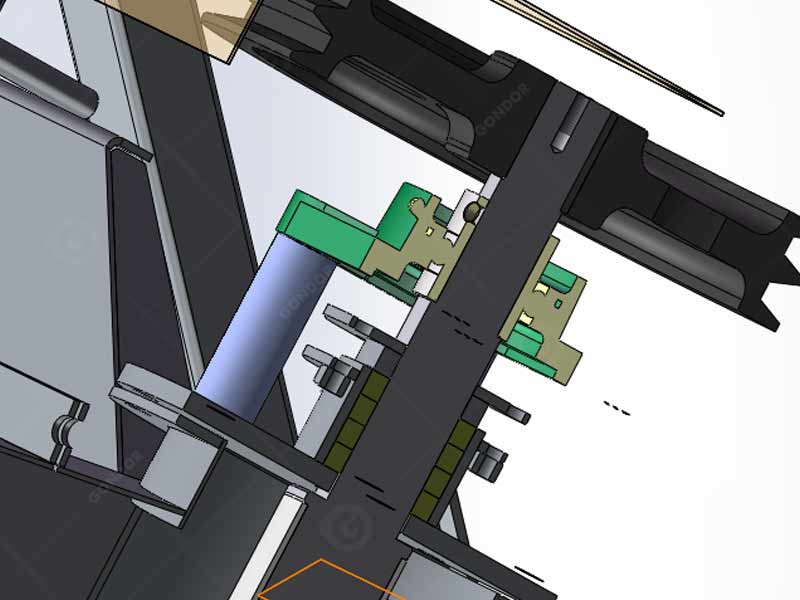

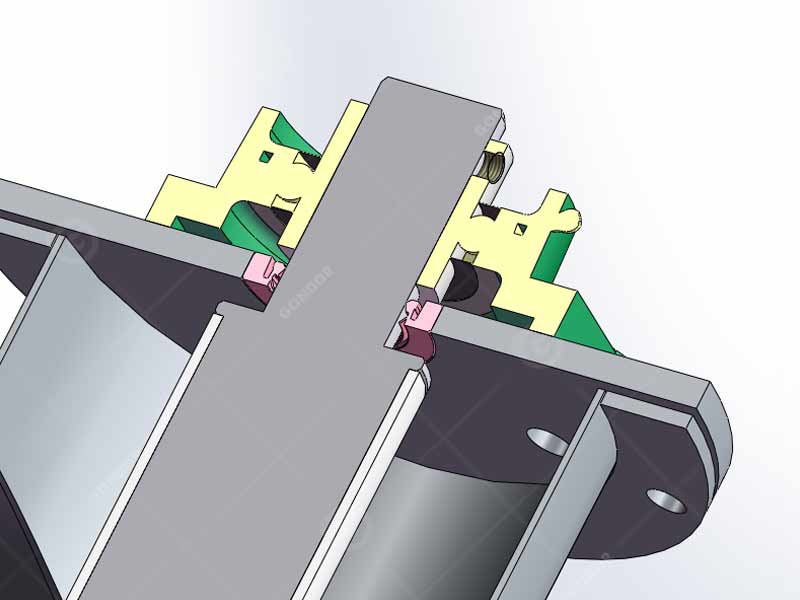

- During the communication process, the client showed a keen interest in the design details of the horizontal mixing machine, particularly focusing on sealing performance and customization features. To address these concerns of our customers, Gondor company provided detailed 3D drawings that showcased the internal structure and operational principles of the equipment. The 3D horizontal mixer design highlighted the mixing structure, discharge outlet design, and sealing mechanisms in great detail.

- Through the professional drawings and comprehensive explanations from our technical teams, this client gained a clear understanding of the design advantages and confirmed that the horizontal mixing machine would effectively resolve the dust leakage issues they were facing on their current production line. For this reason, he finally placed the order on March 28, 2024.

3D Drawing of Gondor Horizontal Mixing Machine

Custom Horizontal Mixing Machine – 3D Drawing

Production: Customom Horizontal Mixing Machine

- Upon receiving the client’s order, our factory immediately launched the production process, which can guarantee the horizontal mixing machine was tailored to the precise specifications of our customer from the USA. What’s more, the entire production cycle was completed in just 30 days, which surpassed his expectations.

- On May 1, 2024, Gondor factory successfully completed the production of the 3200L horizontal mixing machine and arranged the shipment on time. Therefore, this action not only highlighted our efficient production management but also demonstrated the reliable delivery capabilities when handling large orders.

Product Features and Customization Services

There are several customized features which is included in the 3200L horizontal mixer delivered to our client, such as variable frequency stirring, a customized discharge outlet, and high sealing performance. These custom features not only improved the efficiency of the custom horizontal mixing machine but also fully met our customer’s practical production needs.

- Variable Frequency Drive: Our client can adjust the mixing speed according to production needs, which can accommodate the different material mixing requirements.

- Custom Discharge Outlet: The discharge outlet was designed based on the client’s production line to ensure smooth material flow and alignment with the factory processes.

- High Sealing Performance: We designed the horizontal mixer with the feature of enhanced sealing to effectively prevent dust leakage, which can ensure a clean production environment.

Project Challenges and Horizontal Mixer Solutions

Addressing Customization Requirements

- One of the key challenges of the project we faced during the project was meeting various customization requirements from our customers. They requested features such as variable-frequency stirring, a specially designed discharge outlet, and stringent sealing requirements. Each of these posed significant technical demands on the design and manufacturing processes.

- To overcome these challenges, our technical team underwent several rounds of design revisions, with a special focus on enhancing sealing capabilities to ensure no dust leakage during operation. Additionally, to meet the need for variable-frequency stirring, we developed a custom high-efficiency variable-frequency control system, which ensured the machine could function smoothly under different production conditions.

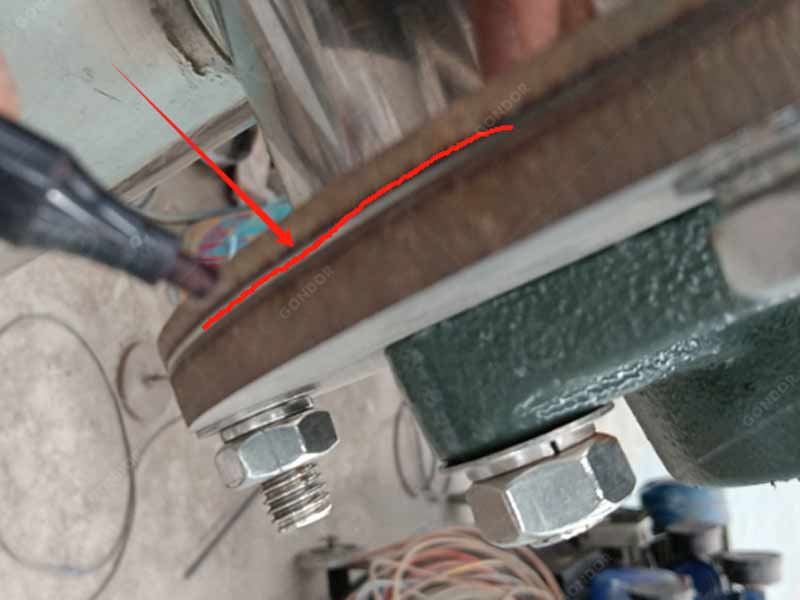

Sealing and Dustproof Design Optimization

- During the communication with our customer, we deeply recognized that their primary concern was the horizontal mixer’s sealing and dust control performance. With the aim of solving the requirement, we optimized the horizontal mixer design to significantly improve sealing through technical innovation, which can ensure that no dust would escape during production.

- After showcasing the sealing system and explaining the related technical advancements, this client expressed strong satisfaction with the dust control performance. To sum up, this breakthrough in technology was a crucial factor in the successful delivery of the project.

Project in the USA: Post-Delivery Feedback of Horizontal Mixer

- After the horizontal mixer was delivered, our client expressed high satisfaction with the exceptional performance of our mixing machinery. Most importantly, they were impressed with the efficiency of the variable-frequency stirring and the custom design of the discharge outlet.

- According to his feedback, the mixer significantly improved production efficiency in actual use. At the same time, the horizontal mixer also effectively solves the dust issue. Consequently, our horizontal mixing machine led to a marked improvement in his factory’s working environment.

- Based on the success of this collaboration, our client expressed a strong interest in deepening their partnership with our company in the future. Simultaneously, this project not only opened new opportunities in the U.S. market but also laid a solid foundation for securing more international orders moving forward.

- We welcome global clients with any needs for different food processing and packaging machinery to reach out to us at any time for food processing machinery quotes and customized solutions.

Strengths of Gondor Machinery in Customized Food Processing Machinery

Specialized Design & Manufacturing Capabilities

As a professional manufacturer of food processing machinery in China, Gondor company possesses extensive experience in both design and manufacturing of different food processing equipment, and we can provide efficient and reliable customized food processing machinery solutions tailored to the specific needs of global clients. Accordingly, our customers can witness the successful 3200L horizontal mixer model, which clearly demonstrates our ability to seamlessly integrate technical innovation with customer requirements.

Efficient Communication and Service Process

From initial communication to final delivery, Gondor machinery demonstrated an efficient and streamlined service process, which can definitely increase the trust of our customers. Moreover, we provided 3D drawings, and professional explanations, and conducted multiple technical discussions. Therefore, our company successfully addressed all client concerns and delivered a high-quality, customized piece of horizontal mixing machine in a short timeframe. To summarize, this efficient and comprehensive service process not only boosted client satisfaction but also earned a strong international reputation for our company.

Supporting Equipment of Gondor Horizontal Mixer for Sale

For global customers who are interested in this customized horizontal mixing machine, it is very likely they also have a plan to buy some related supporting equipment to match their production line. Therefore, you can find some related machines in Gondor machinery. Furthermore, the common supporting equipment for horizontal mixers includes feeding systems, metering devices, dust removal equipment, post-mixing handling systems, temperature control devices, control systems, and cleaning systems. By combining these machines, it ensures efficient, precise, and safe mixing processes, which are suitable for a variety of materials such as powders, granules, and liquids.

If you have any needs or questions, feel free to contact us. We are ready to provide a comprehensive solution to help you achieve a complete upgrade of your production process.